Process technique for incineration tail gas of medical waste, hazardous waste and consumer waste

A technology of domestic waste incineration and hazardous waste, which is applied in the field of domestic waste incineration tail gas treatment process, hazardous waste and medical waste, can solve the problems of incomplete configuration of tail gas treatment process, incomplete purification and disposal, unreasonable temperature control, etc., and achieve improvement The effect of service life, improvement of waste heat recovery utilization rate, energy-saving operation and maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

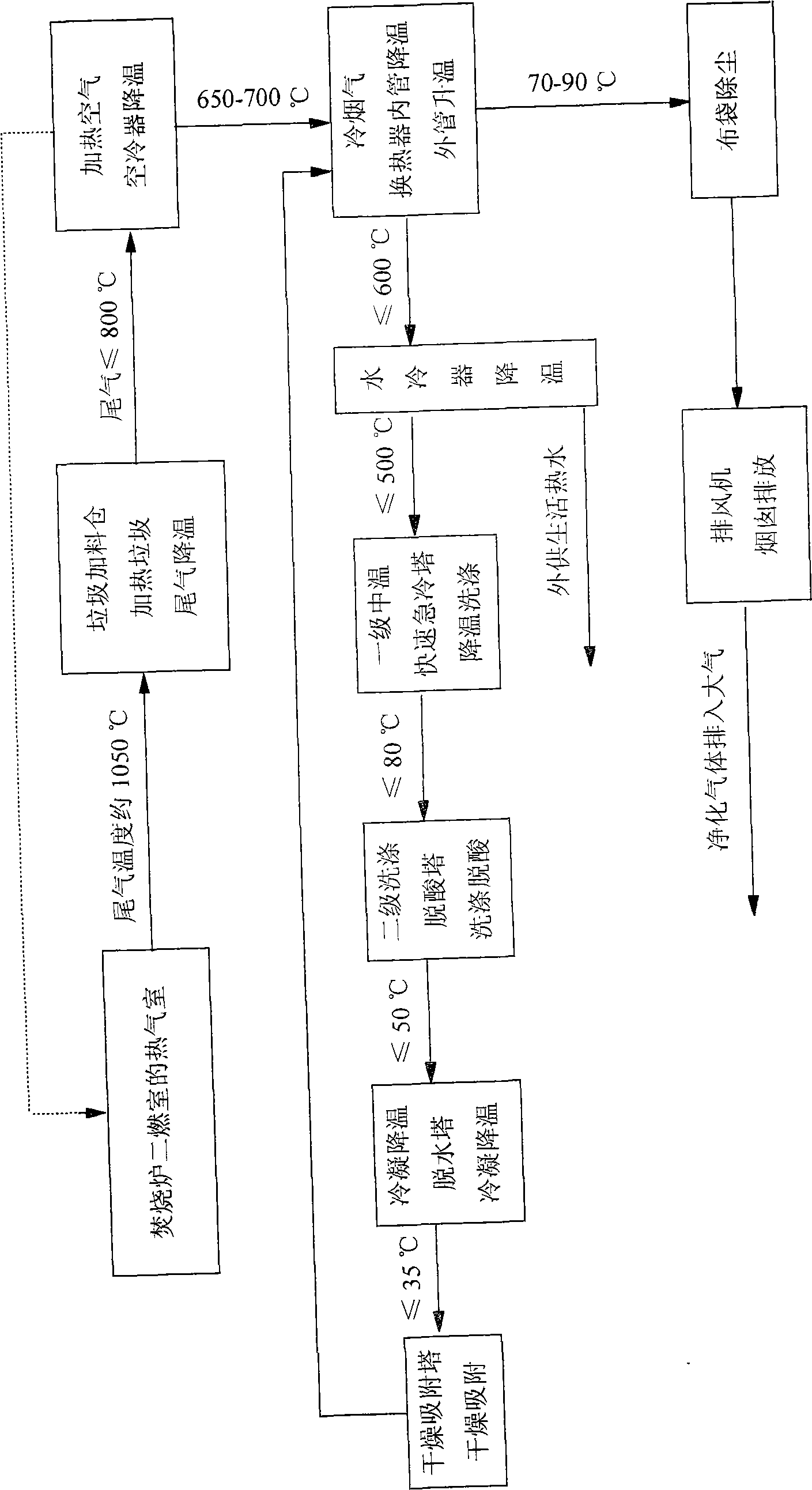

[0042] The present invention is used for the treatment process flow of medical waste (or dangerous goods, household waste) incineration tail gas, see accompanying drawing, comprises the following steps:

[0043] 1. The flue gas discharged from the tail of the second combustion chamber of the incinerator is about 1050°C, and is sent to the waste drying and cracking chamber to heat the waste through the indirect heat transfer of the heat transfer body in the hot gas chamber, for waste heat utilization, and to reduce the flue gas temperature to ≤800°C;

[0044] 2. The temperature is lowered to 650-700°C by the air cooler, the inner cylinder is a high-temperature flue gas channel, and the outer cavity is a secondary oxygen supply air channel, which is heated into the furnace to supply oxygen, and the waste heat is recycled;

[0045] 3. The temperature is lowered to ≤600°C by the cold flue gas heat exchanger. The inner cavity of the heat exchanger is a medium-temperature flue gas ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com