Method and device for generating kinetic energy and refrigerating

A kinetic energy and equipment technology, applied in lighting and heating equipment, refrigerators, mechanical equipment, etc., can solve the problems of not being able to provide a cold source, and not being able to convert heat energy into kinetic energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

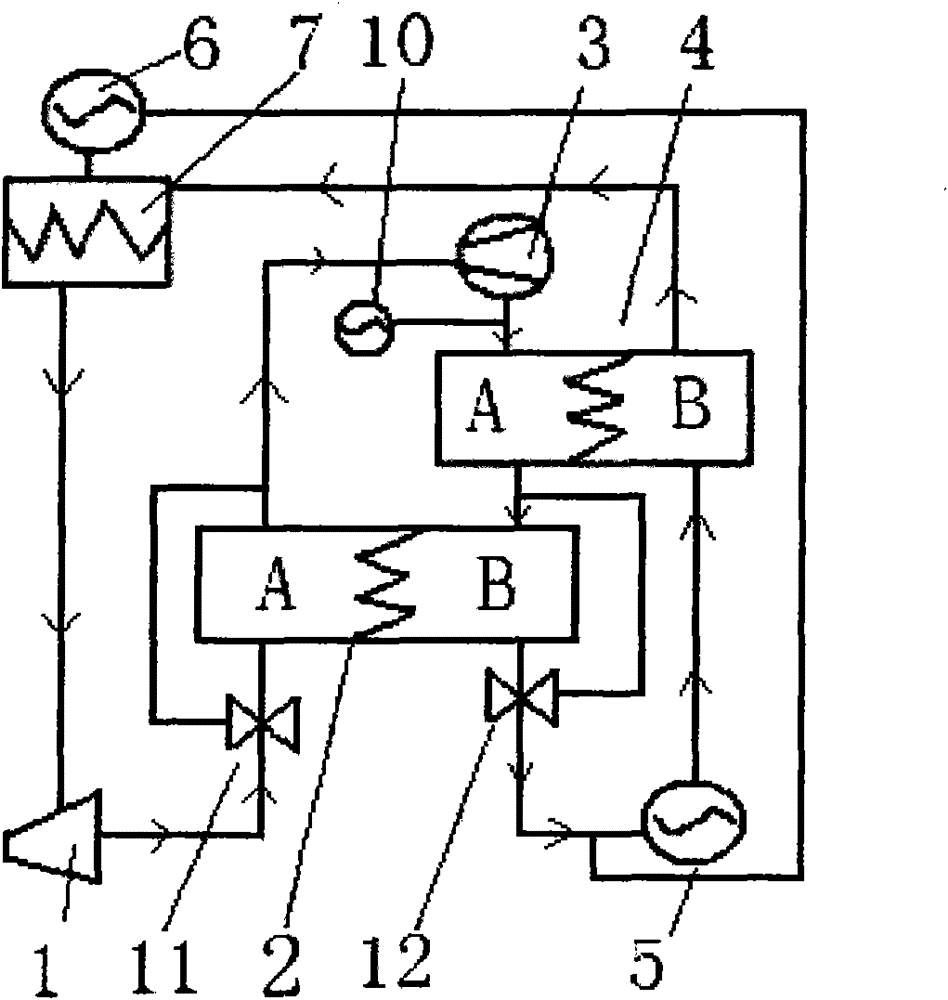

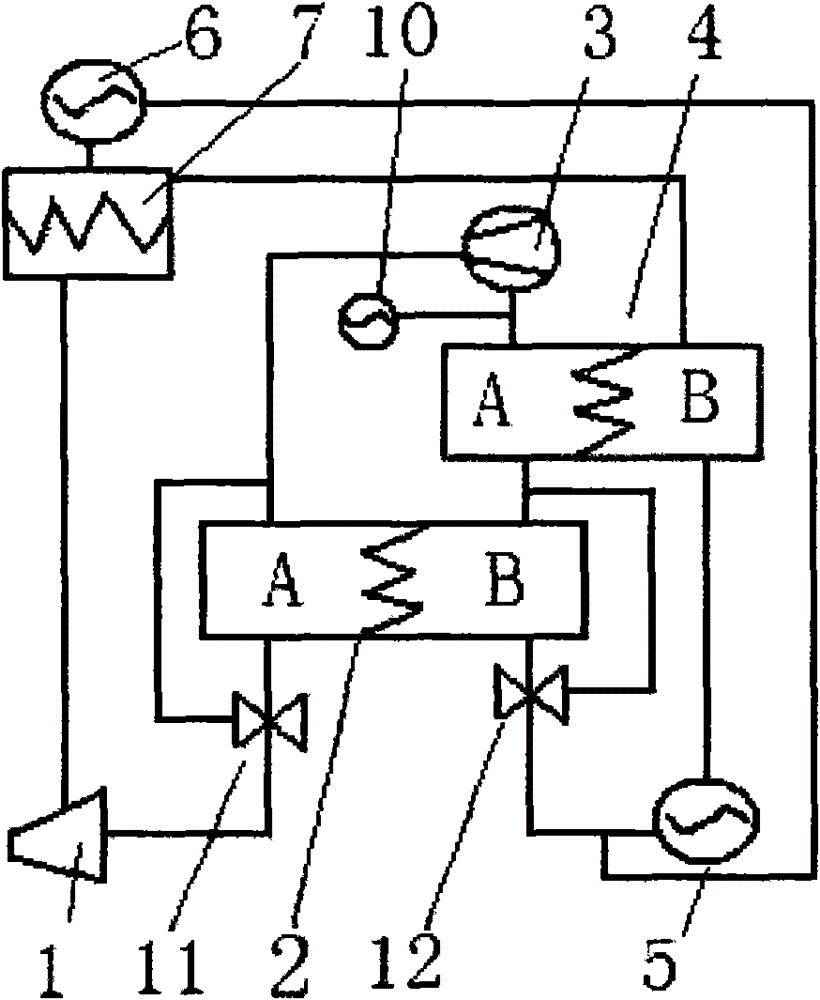

Embodiment 1

[0043] A kind of method for generating kinetic energy and refrigeration, its technical scheme has 11 implementation steps altogether, and its implementation steps are:

[0044] [1] Let the non-condensable gas suction pump (5) pump out the non-condensable gas that needs to be pumped out in the pipeline of the work cycle and the equipment;

[0045] [2] Let the liquid working medium in the evaporator (7) which has a boiling point lower than normal temperature and has no superfluidity when it is in the liquid phase absorb heat from the heat source and heat up;

[0046] [3] Let the work medium in the evaporator (7) that has exchanged heat with the heat source to heat up enter the expander (1) connected to it to do work;

[0047] [4] Let the gaseous working medium flowing out from the outlet of the expander (1) after doing work enter the chamber A of the heat exchanger (2) and then enter the compressor (3);

[0048] [5] Let the compressor (3) compress and heat up the gaseous workin...

Embodiment 2

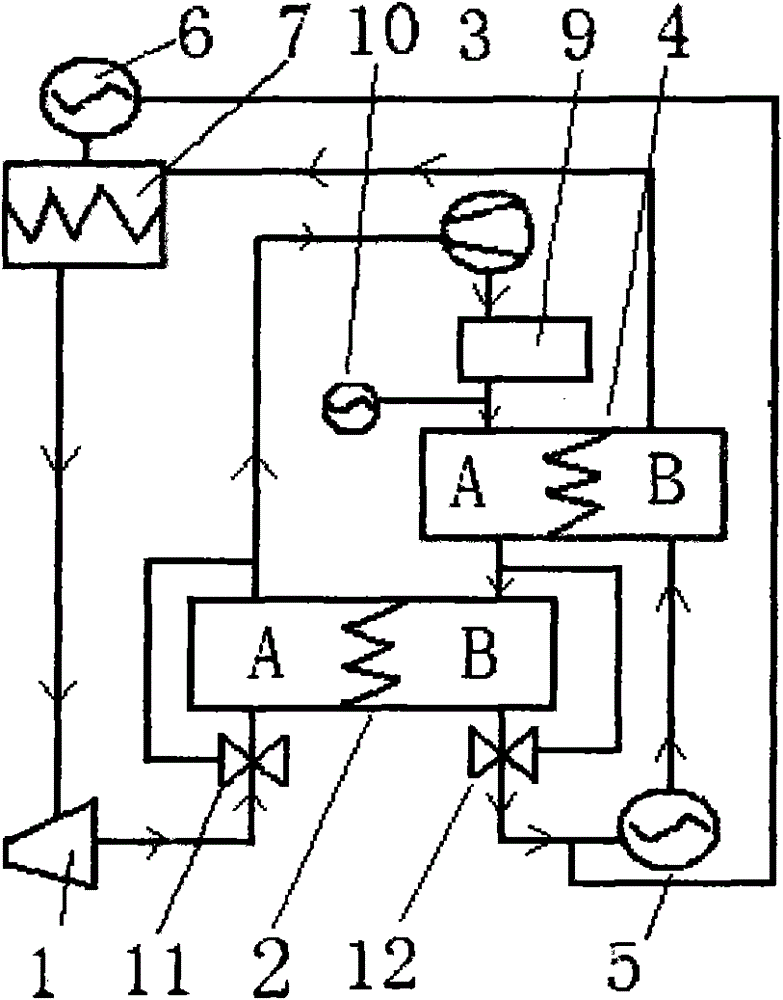

[0068] A device for generating kinetic energy and refrigeration, its structural scheme is: it consists of an expander (1), a heat exchanger (2), a compressor (3), a main heat exchanger (4), a working medium pump (5), Auxiliary working medium pump (6), evaporator (7), vapor-liquid separator (9), non-condensable gas suction pump (10), the working medium outlet of the evaporator (7) is connected with an expander (1) The inlet and the outlet of the expander (1) are connected to the inlet of chamber A of the heat exchanger (2), the outlet of chamber A of the heat exchanger (2) is connected to the inlet of the compressor (3), and the outlet of the compressor (3) is connected to There is the inlet of chamber A of the main heat exchanger (4), and the inlet of the non-condensable gas suction pump (10) is connected to the pipeline between the outlet of the compressor (3) and the inlet of chamber A of the main heat exchanger (4) , the outlet of chamber A of the main heat exchanger (4) is...

Embodiment 3

[0070] A method for generating kinetic energy and refrigeration. The difference between this embodiment and Embodiment 1 is that in the initial working cycle of the working cycle described in Embodiment 1, when the vapor state flowing out of the compressor (3) When the temperature of the working medium exceeds the critical temperature of the vapor working medium, let the refrigerator (9) transfer the vapor working medium between the outlet of the compressor (3) and the inlet of the chamber A of the main heat exchanger (4). The temperature is lowered to below the critical temperature of the working medium in vapor state.

[0071] In the work cycle described in this embodiment, the heat exchange efficiency of the main heat exchanger (4) is directly proportional to the efficiency of the work cycle described in this embodiment.

[0072] This embodiment can also be improved to inject an appropriate amount of liquid working medium whose temperature meets the requirements of the work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com