Comprehensive utilization system of waste heat of ring cooling machine low-temperature exhaust gas and sintering large flue smoke

A flue gas waste heat and ring cooler technology is applied in the field of comprehensive utilization system of sintering waste heat, which can solve the problem of not doing waste heat recovery, and achieve the effect of reducing operating costs and increasing waste heat recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

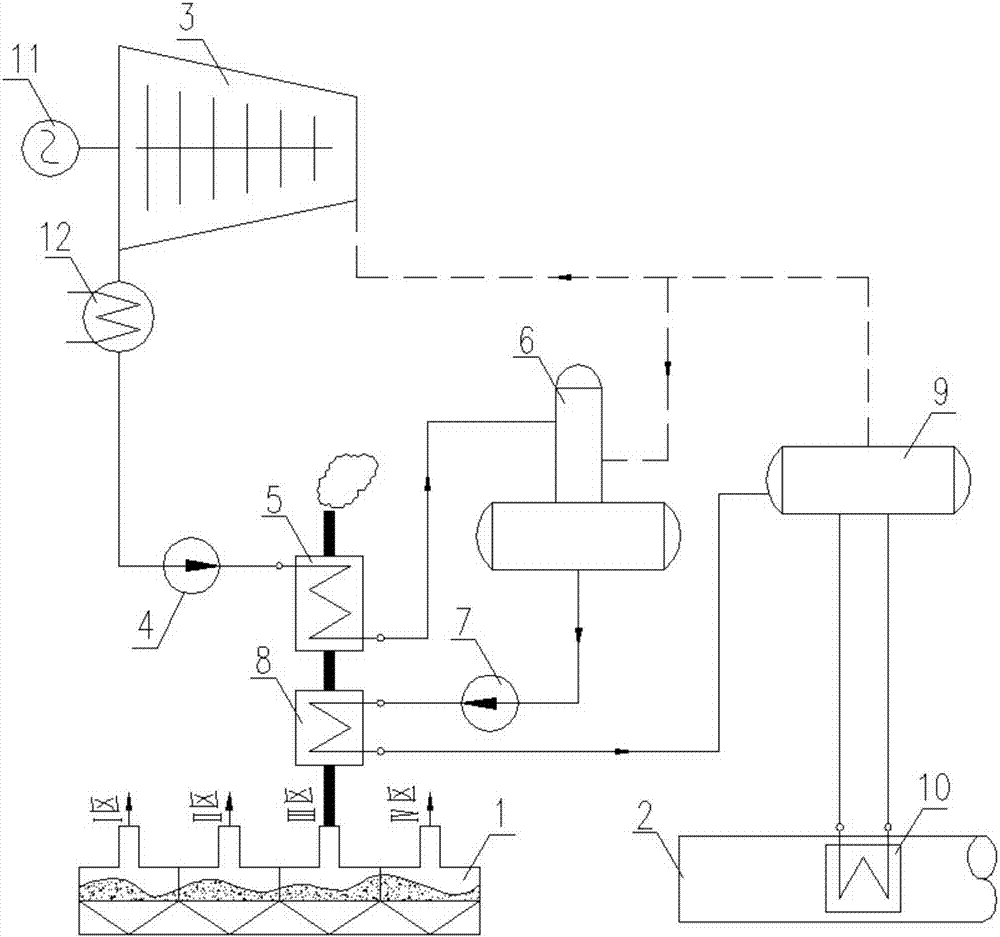

[0024] Such as figure 1 As shown, in this embodiment, the condensed water condensed in the condenser 13 is pumped into the feedwater preheater 5 through the condensate pump 4 to absorb the waste heat of the exhaust gas that has been heat exchanged by the economizer 8, and the temperature rises to the next Enters the deaerator and the water tank 6, the water after deaeration enters the feed water pump 7 to pressurize and then enters the economizer 8, absorbs the low temperature (100~150℃) waste heat of the ring cooler III zone and enters the steam drum In 9, the steam drum 9 and the evaporator 10 are connected to each other through at least two pipelines. The water absorbs the heat of the exhaust gas in the evaporator 10 and then transforms into a steam-water mixture and enters the steam drum 9. This part of the hydraulic cycle relies on the inlet and outlet of the evaporator 10. The weight difference of the medium in the end pipeline is completed, forming a natural circulation ...

Embodiment 2

[0028] On the basis of embodiment 1, the water inlet of the waste heat recovery device in the low temperature zone of the annular cooler is in communication with a water supply pipeline, and the water supply pipeline is provided with a water supply regulating valve group;

[0029] A liquid level sensor is provided in the steam-water separation device, and the feedwater regulating valve group is used to receive a signal sent by the liquid level sensor to control the water level of the steam-water separation device within a preset range.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com