Novel energy conversion system

An energy conversion system and energy conversion technology, applied in steam engine installations, machines/engines, mechanical equipment, etc., can solve problems such as inability to transplant low-grade marine thermal power generation technology, difficult pipeline fixed construction operations, and increased investment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0045] Example 1. Common scheme

[0046] This scheme is suitable for general heat source occasions, including the use of natural environmental heat sources or artificial environmental heat sources, such as factory waste heat, and the water or gas of the heat source needs to be input into the gas-liquid phase combined heat exchange component through the action of a pump or an air pump, so it is called Ordinary program.

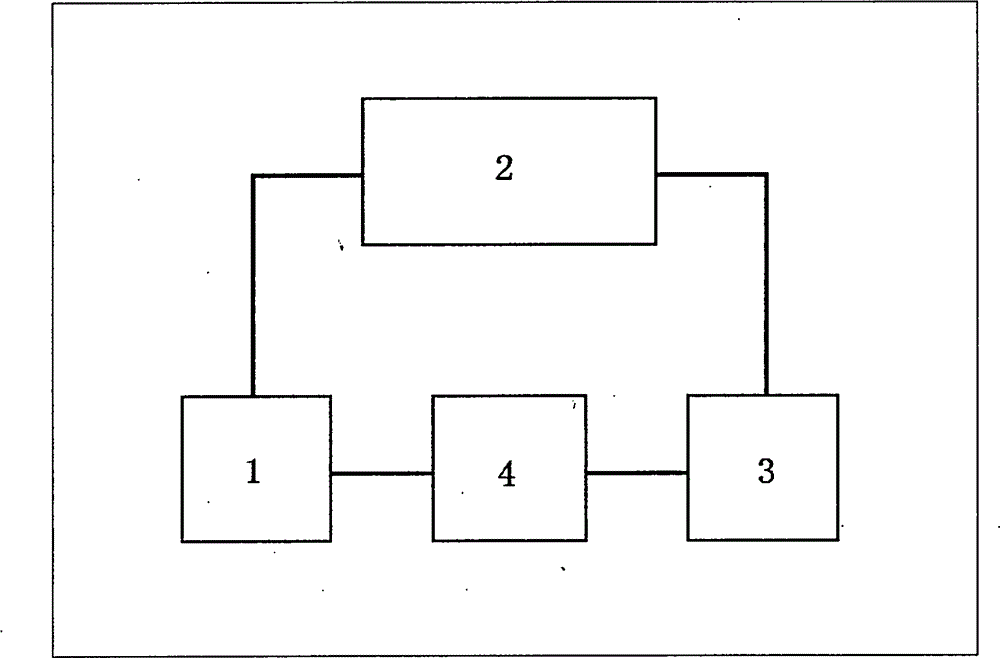

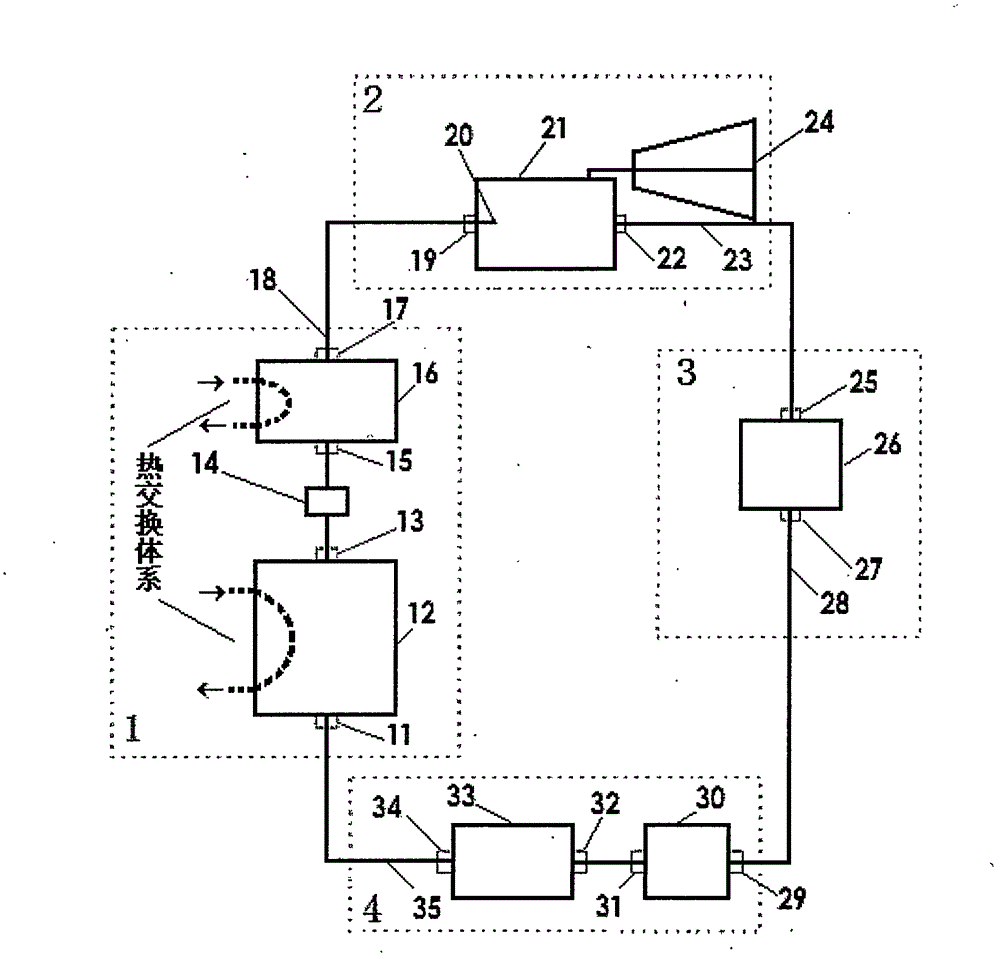

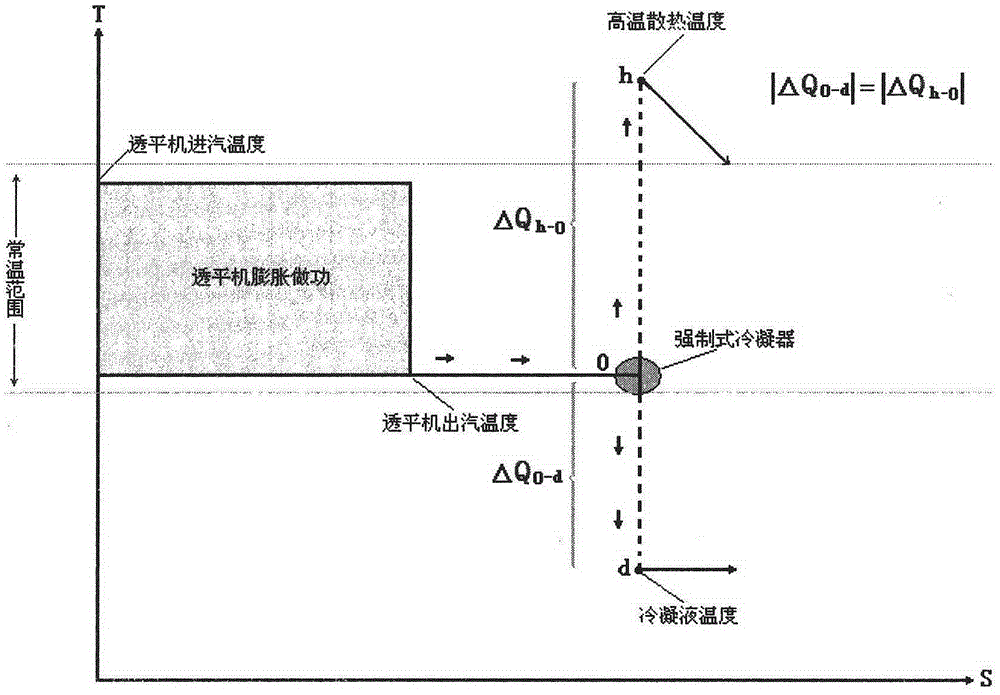

[0047]The heat accumulation mechanism 1, the energy conversion mechanism 2, the cooling and liquefaction mechanism 3 and the working medium circulation mechanism 4 are connected by pipelines in sequence. That is, the liquid inlet valve 11, the liquid phase heat exchanger 12, the check valve 13, the electronic expansion valve 14, the intake valve 15, the gas phase heat exchanger 16, the gas outlet valve 17 in the heat accumulation mechanism 1, and the energy conversion mechanism 2 Inlet valve 19, nozzle 20, pneumatic components 21, outlet valve 22, and inlet va...

example 2

[0051] Example 2. Energy-saving and high-efficiency solution

[0052] Compared with Example 1, this scheme is called energy-saving and high-efficiency type, because it does not need to pump water or air, which reduces the power consumption of water pumping or air pumping, so it is energy-saving and efficient. It is suitable for mountainous rivers with a water temperature above 25-10℃ all year round, with a certain water level gradient, or a certain flow rate, and is also suitable for outputting water flow or airflow in a factory waste heat type with a positioning difference and a certain pressure.

[0053] The system of this scheme is basically the same as Example 1, and the power generation mode is also the same, the difference is how to obtain the heat source water or gas process. In this scheme, the gas-liquid phase combined heat exchange components 12, 16 are directly placed in the flowing river water, so the water (gas) side of the heat exchange system of the gas-liquid p...

example 3

[0054] Example 3. Low-temperature photothermal water storage scheme

[0055] Compared with Example 1, this scheme is called low-temperature photothermal water storage type, because heat storage facilities and light field facilities are added to solve the heat source problem in areas with higher latitude and lower temperature. It is especially suitable for inland environments with long sunlight and unsatisfactory water sources, or marine or lake river environments with sufficient water sources but large temperature differences between day and night.

[0056] The system of this scheme is basically the same as Example 1, and the power generation mode is also the same, the difference lies in the intervention and preparation of the external heat source. In this solution, the light field focusing mirror array uses sunlight to focus and heat the aqueous solution in the storage tank during the daytime. The aqueous solution in the storage tank is the heat source of the system. General...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com