Modified asphalt and its preparation method

A technology for modifying asphalt and asphalt, applied in building components, building insulation materials, buildings, etc., can solve the problems affecting the use effect and low-temperature ductility effect of modified asphalt, affecting the effect of asphalt modification, and huge one-time investment, etc. Achieving the effect of ideal product quality index, non-toxic flash point and reasonable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

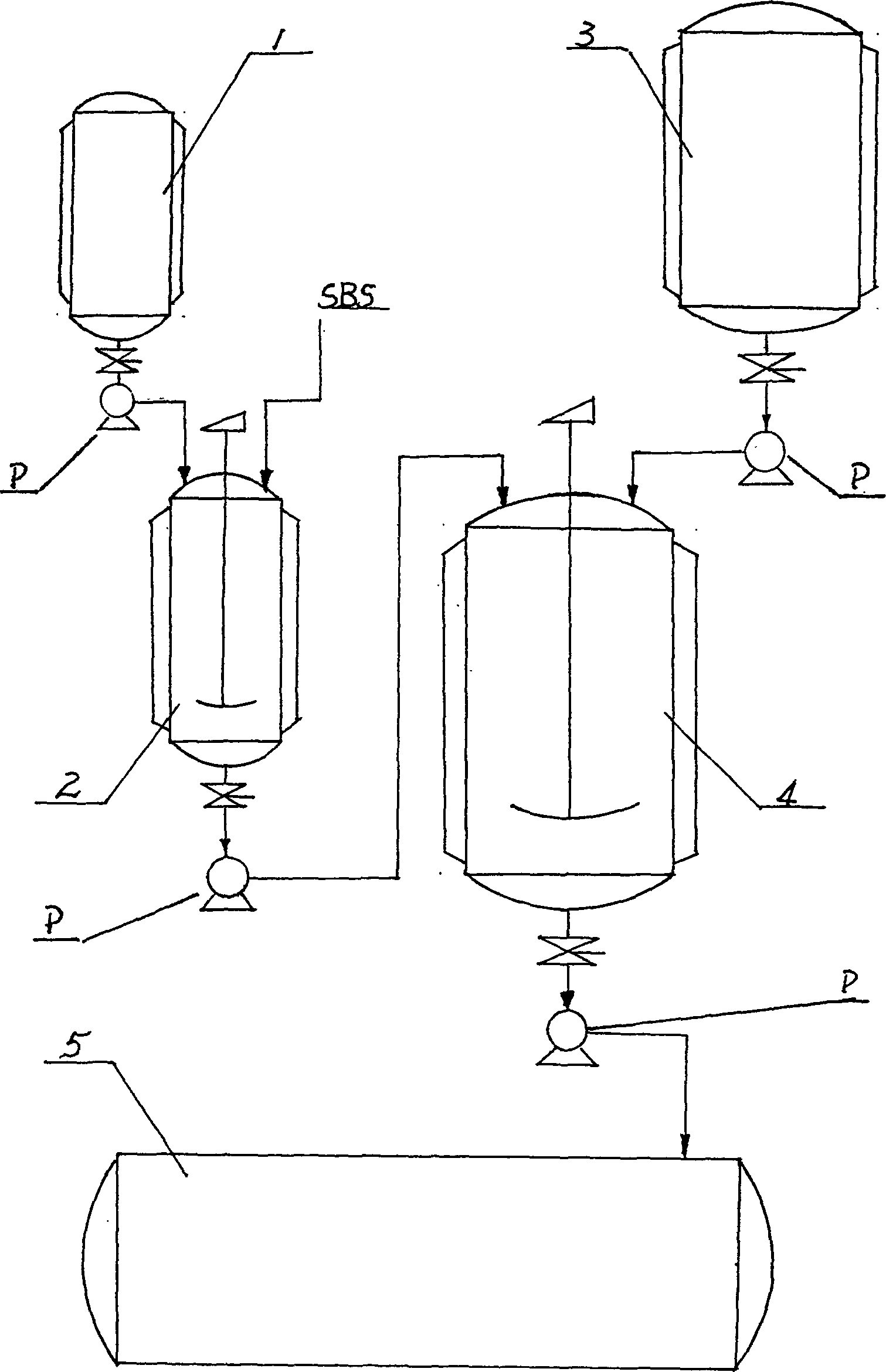

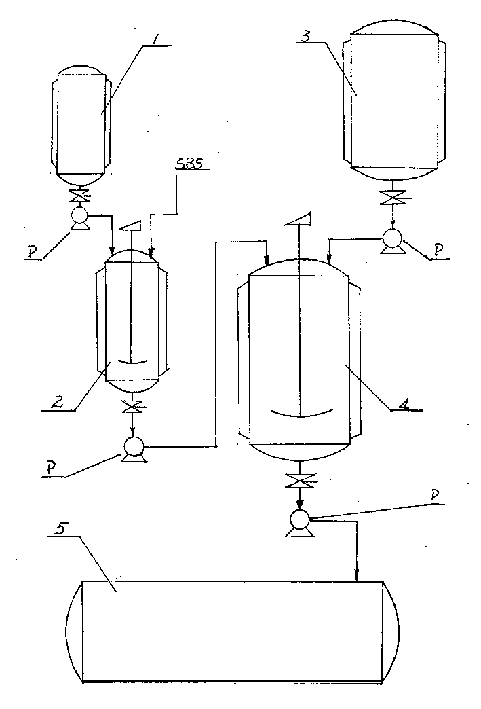

Image

Examples

example ( 1

[0037] Process for preparing modified asphalt: First, heat the extracted oil of secondary refined furfural at 260-560°C to 160°C, and mix it with the same amount of thermoplastic elastomer SBS, and the ratio between them is 1:1. Stir at the same temperature for 35 minutes to make a viscous solution, which is called homogeneous system A. Heat the asphalt to 160°C, mix 10% homogeneous system A with 90% road asphalt, and stir rapidly for 5 minutes to prepare modified asphalt.

[0038] The test results of physical indicators of modified asphalt are shown in Table 1.

example ( 2

[0040] Process for preparing modified asphalt: First, heat the extracted oil of secondary refined furfural at 260-560°C to 160°C, and mix it with the same amount of thermoplastic elastomer SBS, and the ratio between them is 1:1. Stir at the same temperature for 35 minutes to make a viscous solution called homogeneous system A. Heat the asphalt to 160°C, mix 8% homogeneous system A with 92% road asphalt, and stir rapidly for 5 minutes to make modified asphalt.

[0041] The test results of physical indicators of modified asphalt are shown in Table 1.

example ( 3

[0043] Process for preparing modified asphalt: First, heat the extracted oil of secondary refined furfural at 260-560°C to 170°C, mix it with the same amount of thermoplastic elastomer SBS, and the ratio between them is 40:60. Stir at the same temperature for 35 minutes to make a viscous solution, which is called homogeneous system A. Heat the asphalt to 160°C, mix 15% homogeneous system A with 85% road asphalt, and stir rapidly for 5 minutes to prepare modified asphalt.

[0044] The test results of physical indicators of modified asphalt are shown in Table 1.

[0045] experimental project

[0046] It can be seen from Table 1 that there are the following characteristics: (1) Compared with the grinding method, the ductility of the pretreatment method at 5°C is about 2 times that of the grinding method; the ductility of the 0°C method is 19.6-32 times that of the grinding method . (2) Softening point and penetration, the two methods are basically similar. The equiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com