Optimization method for determining flue gas excess heat organic Rankine cycle system parameter

A flue gas waste heat and circulation system technology, applied in design optimization/simulation, data processing applications, general water supply saving, etc., can solve the problems of large cooling water demand, large heat release during condensation process, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

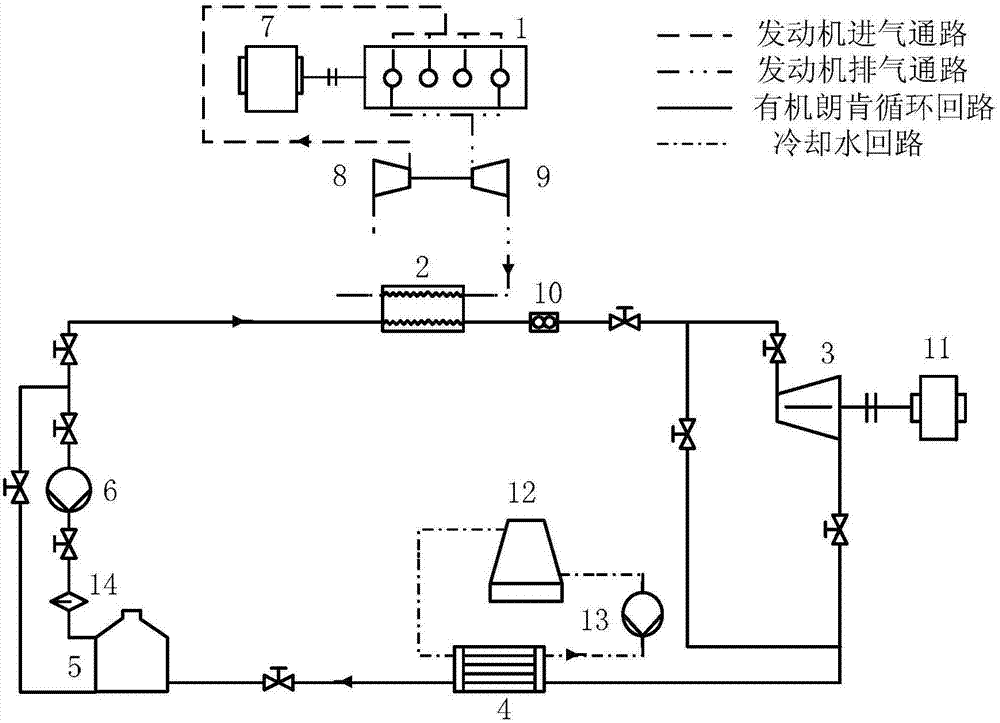

[0088] An optimization method for determining the parameters of the flue gas waste heat organic Rankine cycle system of the present invention will be described in detail below with reference to the embodiments and the accompanying drawings.

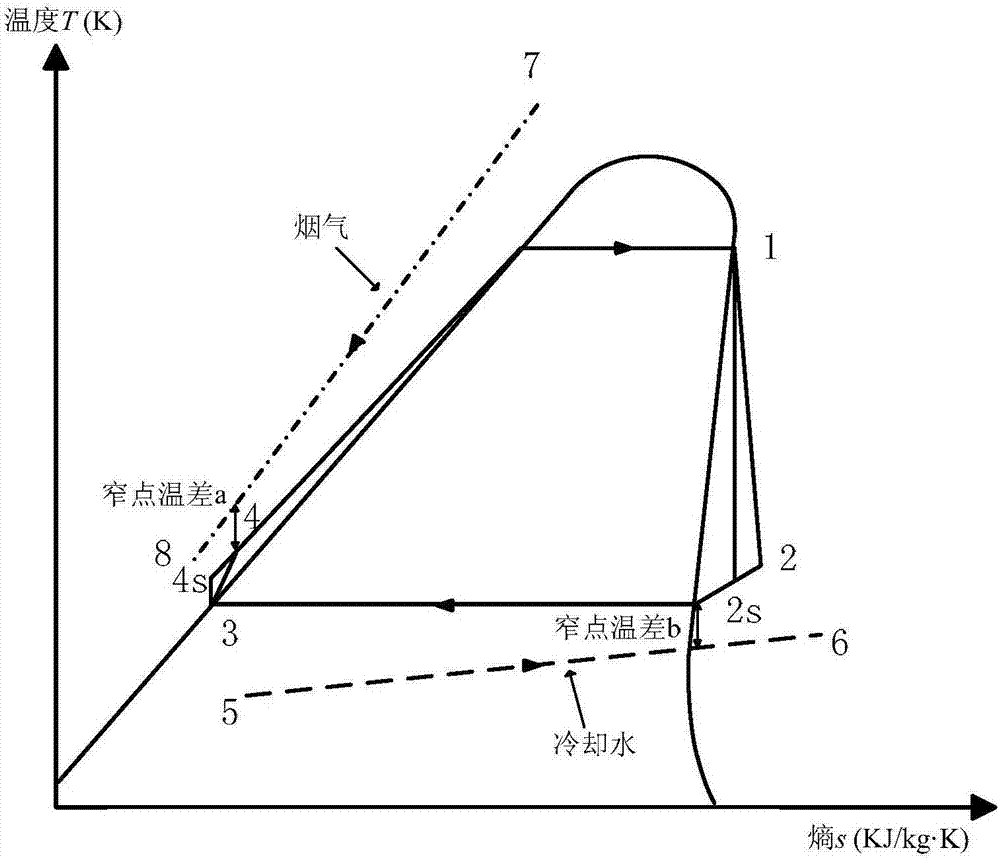

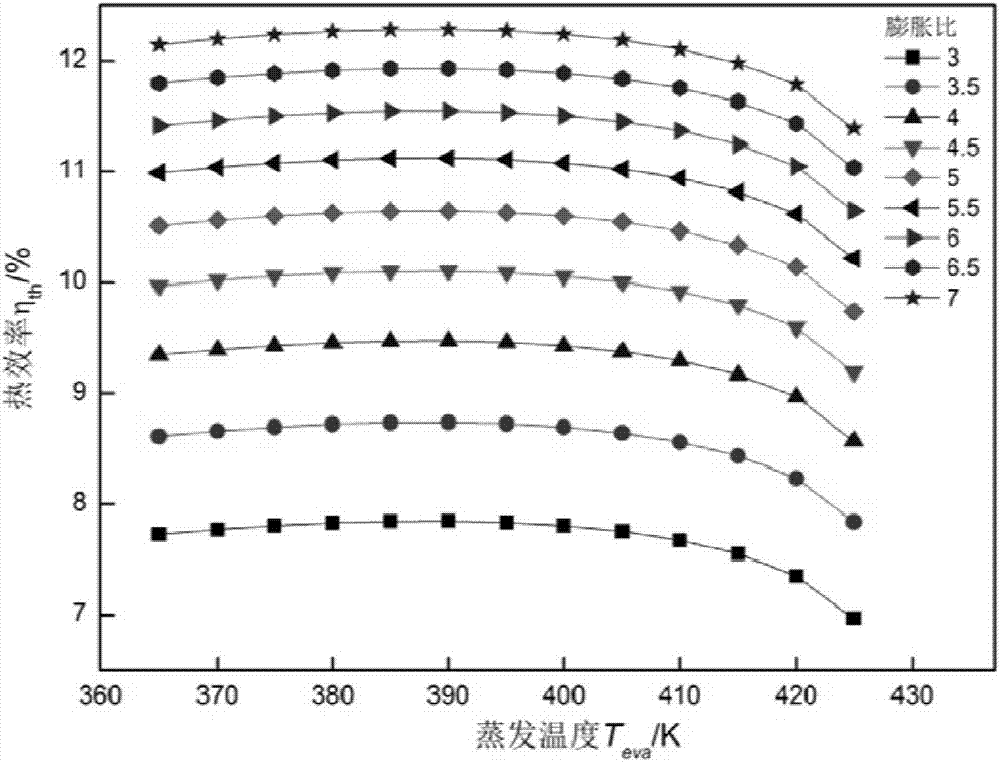

[0089] The purpose of an optimization method for determining the parameters of the flue gas waste heat organic Rankine cycle system of the present invention is to analyze the thermodynamics of the system performance by the first law of thermodynamics and the second law of thermodynamics, optimize the optimum evaporation temperature, and optimize the evaporation temperature from the evaporator and condenser. Analyze the economic performance of the organic Rankine system from the angle of area and net output power, comprehensively consider the thermodynamic performance and economic performance, and then optimize the optimal condensation temperature, so as to determine the optimal system parameters, and provide a widely used flue gas waste hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com