Beverage portioned package for preparing a foamy beverage from soluble powder

a technology of soluble powder and beverage, which is applied in the direction of packaging, food packaging, packaged goods, etc., can solve the problems of not being well adapted to preparation, affecting the control of solid concentration, and the pressure in the portioned package would tend to drop rapidly

Inactive Publication Date: 2005-07-21

NESTEC SA

View PDF14 Cites 128 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

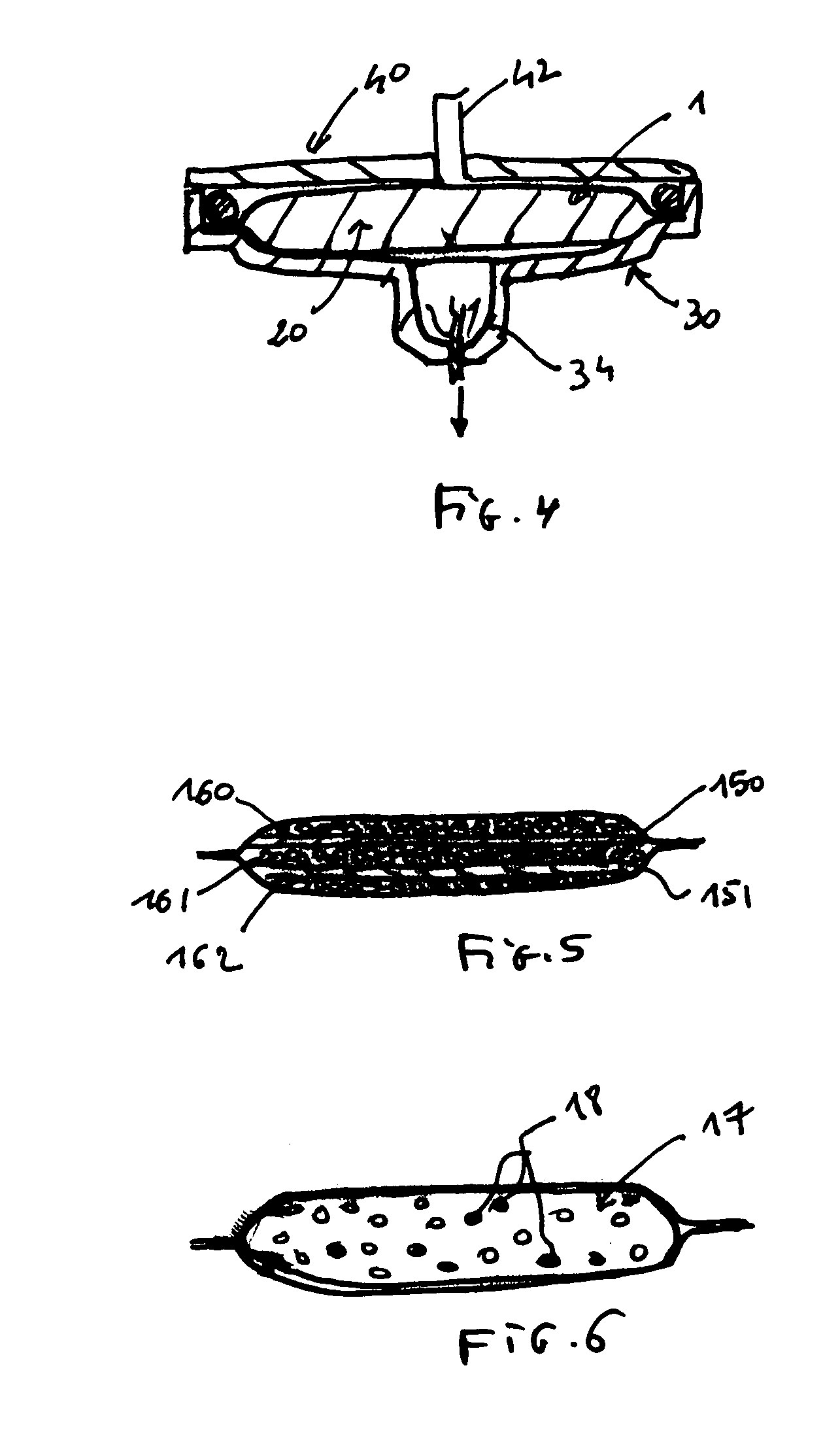

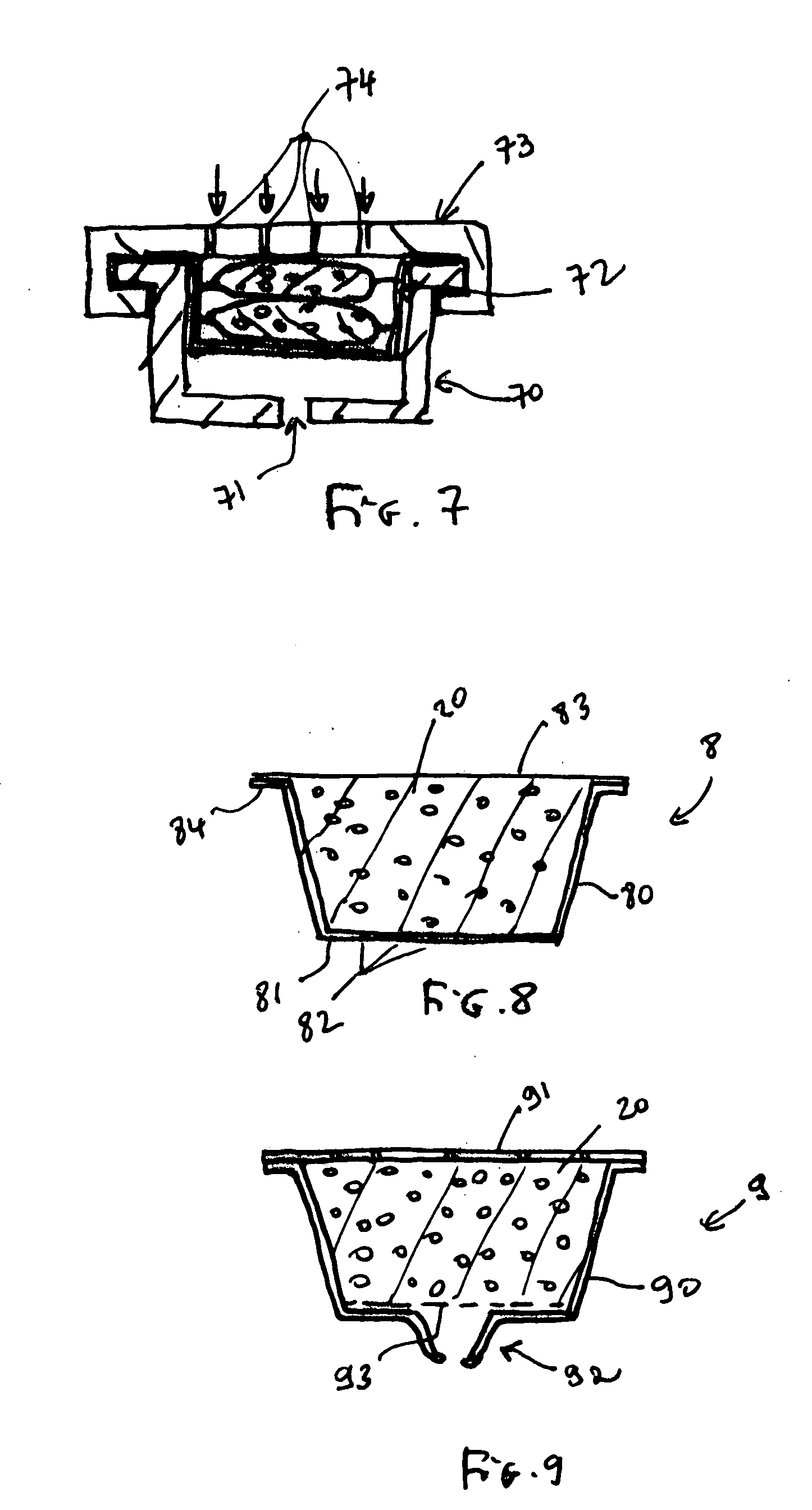

[0008] The filler performs to maintain a sufficient pressure of extraction during extraction of the portioned package while the water-soluble beverage material progressively dissolves in water, as water passes through the package to release the beverage. The pressure inside the portioned package, which can be so maintained at a sufficient level until the portion of soluble material has been dissolved, contributes to ensure that the beverage delivers the desired solids concentration and that a sufficient amount of foam is also created. These properties are significantly improved over portioned packages that do not include such a filler. For packages comprising flexible walls, the filler also acts to maintain the proper volume and size of the package during and after the extraction process and prevent the package from collapsing in the extraction chamber.

[0009] Preferably, the filler is configured for avoiding a drop of the pressure of extraction. Thanks to the filler, the maximum pressure reduction during the extraction of the package can be maintained lower than 0.2 bars, preferably lower than 0.05 bar, until full completion of the beverage delivery.

Problems solved by technology

However, they are not well adapted to prepare, from soluble powder, a beverage with a sufficient solids concentration and decent foam.

In this regard, it has been found that the pressure in the portioned package would tend to drop rapidly before the end of the beverage delivery.

The drop of pressure is detrimental to a full dissolution of the powder in the package, consequently, it is detrimental to the control of the solids concentration in the final liquid delivered since soluble material does not dissolve entirely and some soluble material remains in the package.

This patent, however, does not remedy the deficiencies of the art.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example

[0058] A pod was made using 4.5 g spent coffee ground to 390 microns and 2 grams of soluble coffee. The ingredients were mixed thoroughly and sealed in two layers of disc-shaped filter paper with a diameter of 69 mm, a dry tensile strength of 180 gram per millimeter. This pod was used to prepare a black coffee beverage of 120 mL with a layer of foam of about 15% of the volume beverage.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

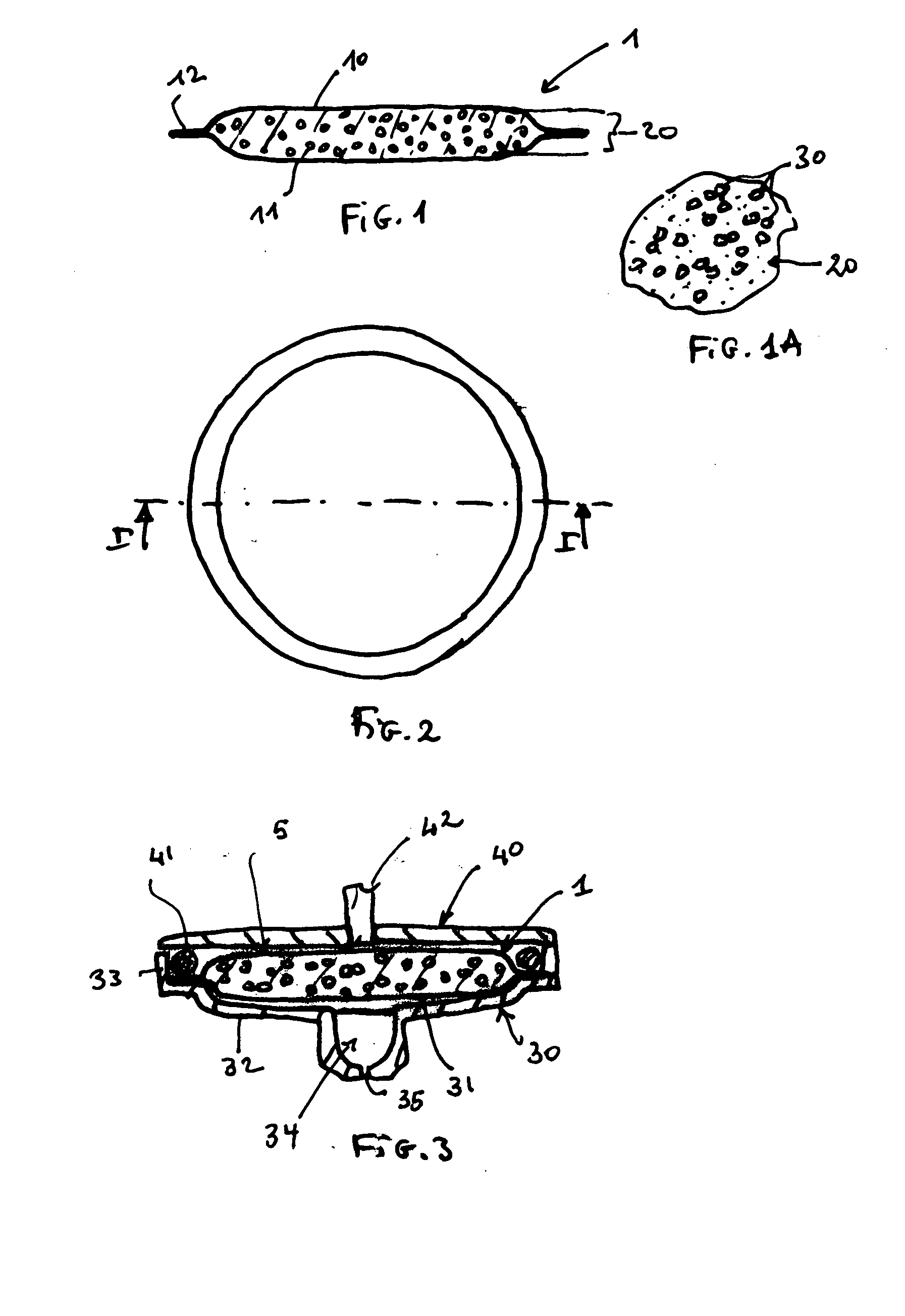

A beverage portioned package for preparing a beverage in an extraction device of which the package is held or clamped between a water supplying part and a receiver of the device. The package has a first surface for the water to be forced to flow there through under pressure when the package is held or clamped in the device; a second surface for the flow of beverage to be forced to flow there through so to be collected in the receiver, wherein the package contains a portion of water-soluble beverage material and a portion of a filler. The filler comprising water insoluble material adapted to maintain the extraction pressure above the pressure created by the sole resistance of the first and second surfaces when the package is emptied of said soluble material.

Description

FIELD OF THE INVENTION [0001] The invention relates to a beverage portioned package with soluble powder for preparing a foamy beverage in an extraction device in which the package is held or clamped and water is injected under pressure therethrough. BACKGROUND OF THE INVENTION [0002] Foamed beverages, such as espresso, cappuccino or latte can be dispensed from portioned packages that are placed inside a beverage machine. Pre-metered and pre-packed portions of coffee and the like for the preparation of coffee-based beverages facilitate the preparation of the beverage while ensuring that the dose-to-dose quality and strength of the beverage remains constant for the same conditions of preparations (dosage, temperature, pressure, time, etc.). It also provides convenience to the user. The portioned package usually sits in a leak-tight enclosure of an espresso type coffee machine, and hot water is passed under pressure through the portion of coffee. A receiver forming the underside of the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B65B29/02B65D85/804

CPCB65D85/8046B65D85/8043

Inventor HU, RUGUOMAGEL, LILIAN K.SCOVILLE, AMANDA

Owner NESTEC SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com