Underground hydraulically-driven spiral-rotational flow coupling tubular separator

A technology of hydraulic drive and separator, which is used in the production of fluids, wellbore/well components, earth-moving drilling, etc. It can solve the problems of wellbore, equipment erosion, wear and blockage, goaf reservoir collapse, and wellbore instability, etc. problems, to avoid erosion, wear and blockage, reduce the volume of riser pipe, and reduce pump power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention includes but not limited to following description:

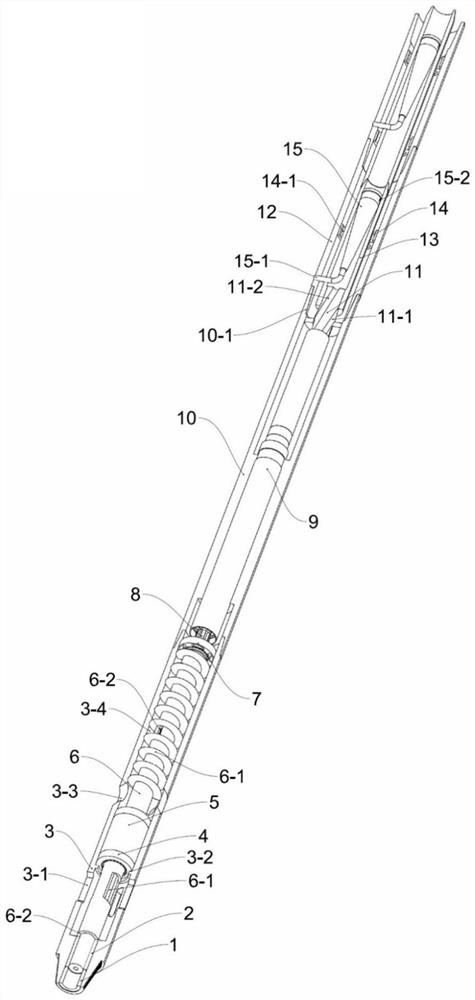

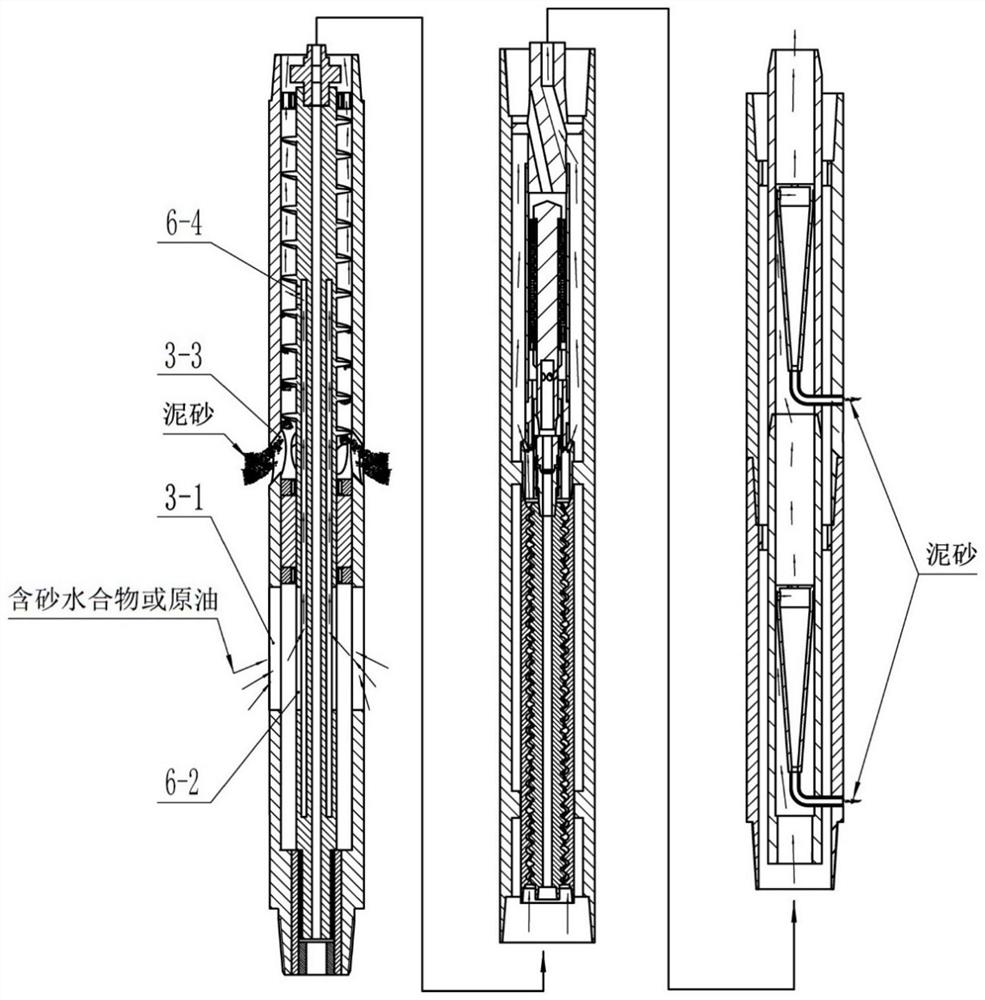

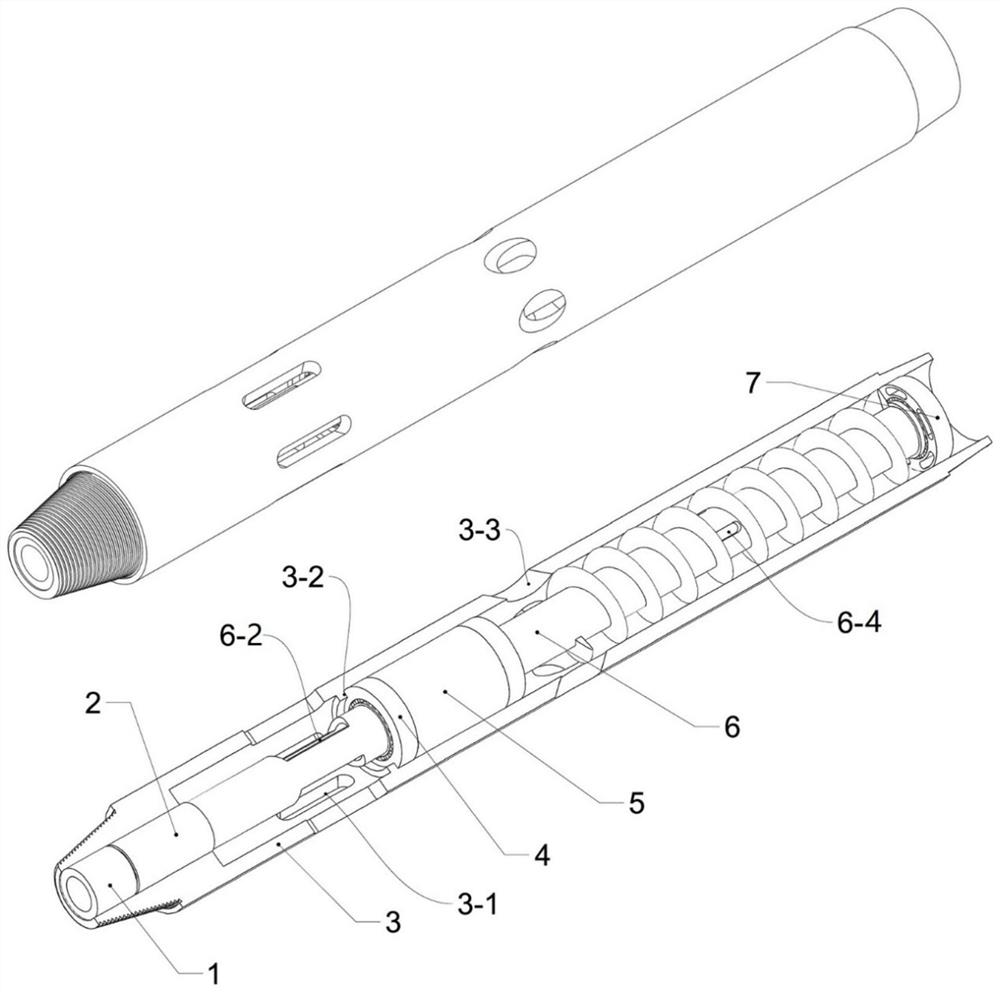

[0054] Such as Figure 1 to Figure 10 As shown, a downhole hydraulically driven spiral-swirl coupled tubular separator is characterized in that it includes three parts: a spiral crushing and separating device, a hydraulic motor screw pump device, and a multi-stage swirling fine separating device;

[0055] The screw crushing and separating device is composed of a packing gland 1, a dynamic sealing packing 2, a spiral crushing and separating device shell 3, an axial positioning bearing 4, a sealing cylinder section 5, a separating screw 6, and an overflow bearing I7. The dynamic sealing packing 2 Installed at the lower end of the shell 3 of the spiral crushing and separating device, the packing gland 1 is connected to the lower end of the shell 3 of the spiral crushing and separating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com