Special reactive typehigh-activityleveling agent for epoxy powder coatings as well as preparation method and application of leveling agent

An epoxy powder, reactive technology, applied in powder coatings, epoxy resin coatings, coatings, etc., can solve the problems of poor resin compatibility, poor substrate wettability, etc., to improve the compactness of the coating and improve the durability Solvent performance, effect of leveling improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

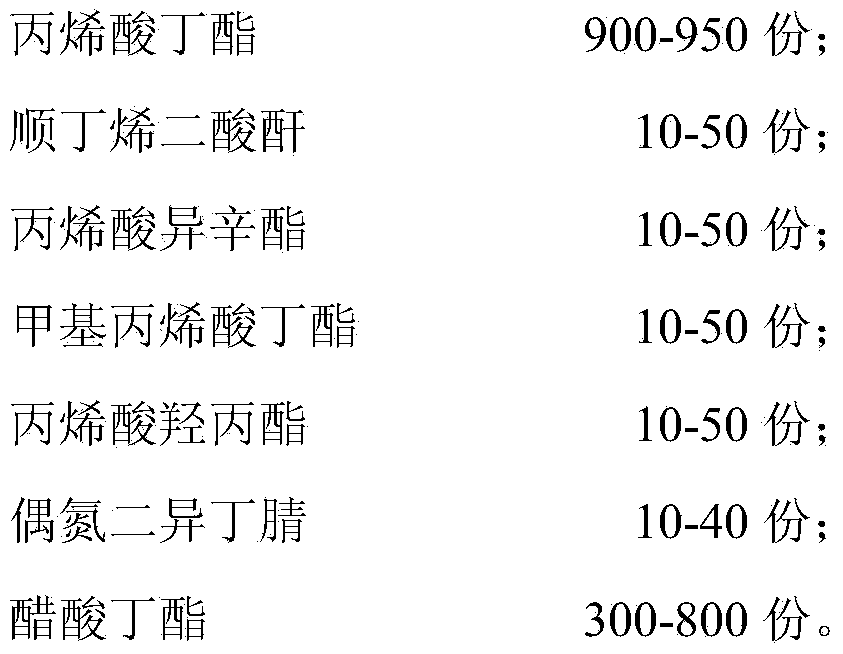

[0023] A special reactive type high activity leveling agent for epoxy powder coatings, its raw material constituents and weights are respectively:

[0024]

[0025] The preparation method of the above-mentioned special reactive type high activity leveling agent for epoxy powder coatings, the steps are as follows:

[0026] The butyl acetate and butyl acrylate of the above weight are sucked into the reaction kettle under negative pressure, and the stirrer is started to heat and reflux while maintaining a balanced state;

[0027] (2) Mix azobisisobutyronitrile, butyl methacrylate, hydroxypropyl acrylate, isooctyl acrylate, and maleic anhydride evenly, suck them into the additive dropping tank, and control the dropping rate and reaction kettle temperature , The dropwise addition is completed within 2 hours, and then the reaction is continued at 100-105°C for 3-6 hours, and then distilled under reduced pressure until there is no distillate, and weighed under cooling.

Embodiment 2

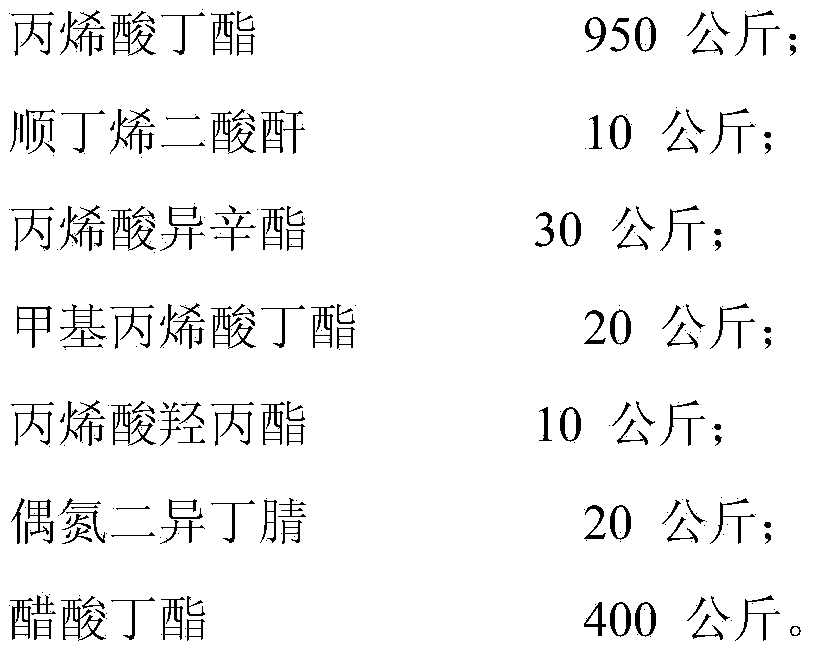

[0029] A special reactive type high activity leveling agent for epoxy powder coatings, its raw material constituents and weights are respectively:

[0030]

[0031] The preparation method of the above-mentioned special reactive type high activity leveling agent for epoxy powder coatings, the steps are the same as in Example 1.

Embodiment 3

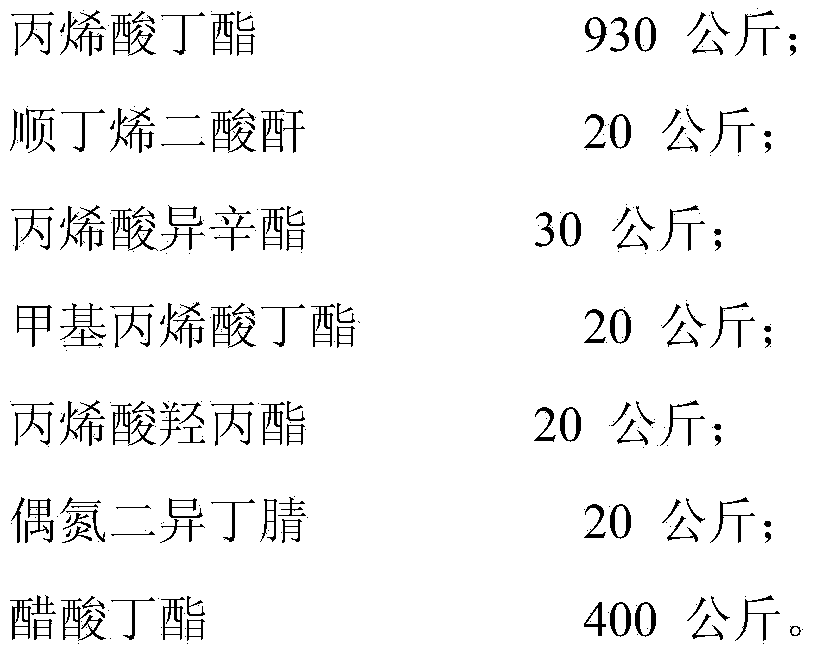

[0033] A special reactive type high activity leveling agent for epoxy powder coatings, its raw material constituents and weights are respectively:

[0034]

[0035] The preparation method of the above-mentioned special reactive type high activity leveling agent for epoxy powder coatings, the steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com