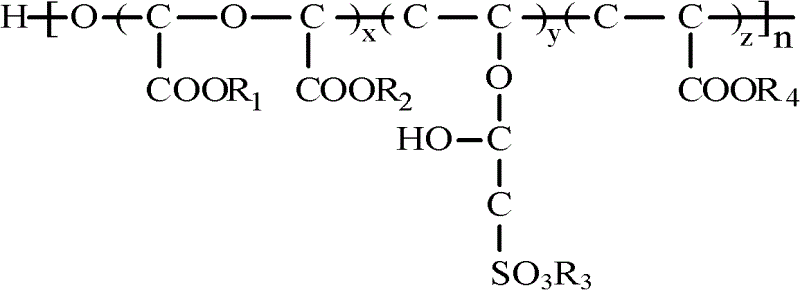

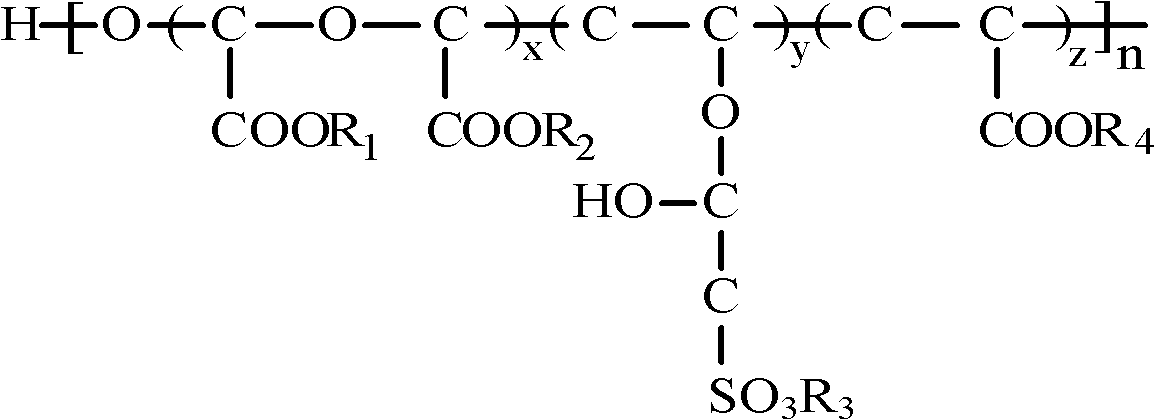

Biodegradable corrosion and scale inhibitor epoxy succinic acid copolymer and its preparation method

A corrosion and scale inhibitor, epoxy succinic acid technology, applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc., can solve the problem of high cost, high catalyst requirements, epoxy succinate The problem of single type of acid water treatment agent, etc., to achieve the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

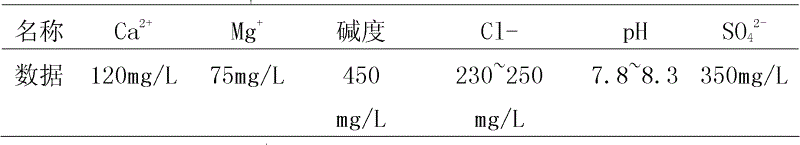

Examples

Embodiment 1

[0023] Embodiment 1: Preparation of epoxy succinic acid / acrylic acid / 3-allyloxy-2-hydroxyl-1-propanesulfonic acid monosodium salt copolymer

[0024] Add 38.67g of maleic anhydride and 15.78g of potassium hydroxide to a four-necked flask equipped with a thermometer, a condenser, a dropping funnel and a constant-speed stirring device, dissolve them in deionized water, and add 1.21 g catalyst 1 ammonium molybdate, and then slowly add 30% hydrogen peroxide dropwise to the solution under stirring condition, and the pH of the reaction solution is 3-4 after the dropwise addition is completed. The reaction is continued for 1 hour at a temperature of 60-90° C. under stirring conditions to synthesize the intermediate epoxysuccinic acid. At a temperature of 60-90°C, under stirring conditions, after adding 22.13g of catalyst potassium hypophosphite to the solution, 134.95g of acrylic acid and 7.11g of 3-allyloxy-2-hydroxyl-1-propanesulfonic acid were added dropwise at the same time The m...

Embodiment 2

[0025] Embodiment 2: Preparation of epoxy succinic acid / acrylic acid / 3-allyloxy-2-hydroxyl-1-propanesulfonic acid monosodium salt copolymer

[0026]Add 38.67g of maleic anhydride and 20.45g of sodium hydroxide to a four-necked flask equipped with a thermometer, a condenser, a dropping funnel and a constant-speed stirring device, dissolve them in deionized water, and add 1.67g when the temperature rises to 60-90°C g catalyst 1 sodium tungstate, and then slowly add 30% hydrogen peroxide dropwise to the solution under stirring conditions, and the pH of the reaction solution is 3-4 after the dropwise addition is completed. The reaction is continued for 2 hours at a temperature of 60-90° C. under stirring conditions to synthesize the intermediate epoxysuccinic acid. At a temperature of 60-90°C, under stirring conditions, after adding 20.81g of catalyst ammonium phosphite twice, 161.94g of acrylic acid and 8.525g of 3-allyloxy-2-hydroxyl-1-propanesulfonate were added dropwise at the...

Embodiment 3

[0027] Embodiment 3: Preparation of epoxy succinic acid / acrylic acid / 3-allyloxy-2-hydroxyl-1-propanesulfonic acid monosodium salt copolymer

[0028] Add 58.0g of maleic anhydride and 26.04g of sodium hydroxide to a four-neck flask equipped with a thermometer, condenser, dropping funnel and constant speed stirring device, dissolve them with deionized water, and add 2.5 g catalyst 1 ammonium vanadate, and then slowly add 30% hydrogen peroxide dropwise to the solution under stirring condition, and the pH of the reaction solution is 3-4 after the dropwise addition is completed. The reaction is continued for 2 hours at a temperature of 60-90° C. under stirring conditions to synthesize the intermediate epoxysuccinic acid. At a temperature of 60-90°C, under stirring conditions, after adding 23.32g of catalyst sodium phosphite twice, 158.54g of acrylic acid and 11.93g of 3-allyloxy-2-hydroxyl-1-propanesulfonate were added dropwise at the same time A mixed solution of acid monosodium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com