Organic environmentally-friendly soil conditioner for improving acidified or acid soil

A technology of soil conditioner and acidic soil, applied in the field of organic environment-friendly soil conditioner and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of the organic environment-friendly soil conditioner of improving acidification or acid soil according to the present invention, the steps are as follows:

[0026] (1) Biogas residue pretreatment: the biogas residue with animal manure and straw as the main raw material is separated from solid and liquid to obtain biogas residue with a water content of 50wt% to 60wt%, and then air-dried or dried to obtain a water content of less than 30wt% biogas residue; shear and crush the biogas residue to a fineness of 0.5-1 mm;

[0027] (2) Pretreatment of shell powder: Rinse natural scallop shells, oyster shells, green clam shells, carved clam shells, meretrix meretrix shells or mixed shells with clean water, dry them to constant weight, place them in a kiln, and heat Carry out high-temperature calcination at 900-1000°C for 30-60 minutes, cool down to room temperature, then grind and pass through a 200-mesh sieve to obtain shell powder;

[0028] (3) Add the ...

specific Embodiment approach

[0055] Below in conjunction with embodiment, the present invention will be further described, what is not described in detail in the embodiment is all by the prior art in this area, and the raw material used in the embodiment is as follows:

[0056] Calcium magnesium phosphate fertilizer is available from Fuquan Phosphate Fertilizer Factory in Guizhou Province; chitosan, deacetylation degree > 80%, is available from Jinan Haidebei Marine Bioengineering Co., Ltd.; plant ash is from Guoneng Gaotang Biological Power Plant; zeolite powder and bentonite , Xinyang City Pingqiao District Jinchuan Mining Flour Mill for sale. Other raw materials without special instructions are commercially available conventional products.

[0057] Examples The solid-liquid separator used in the preparation method is a Hansen brand LX 280-2 spiral solid-liquid separator, available from Zibo Hansen Machinery Co., Ltd. The biogas residue is sheared and pulverized using a wet material pulverizer, which i...

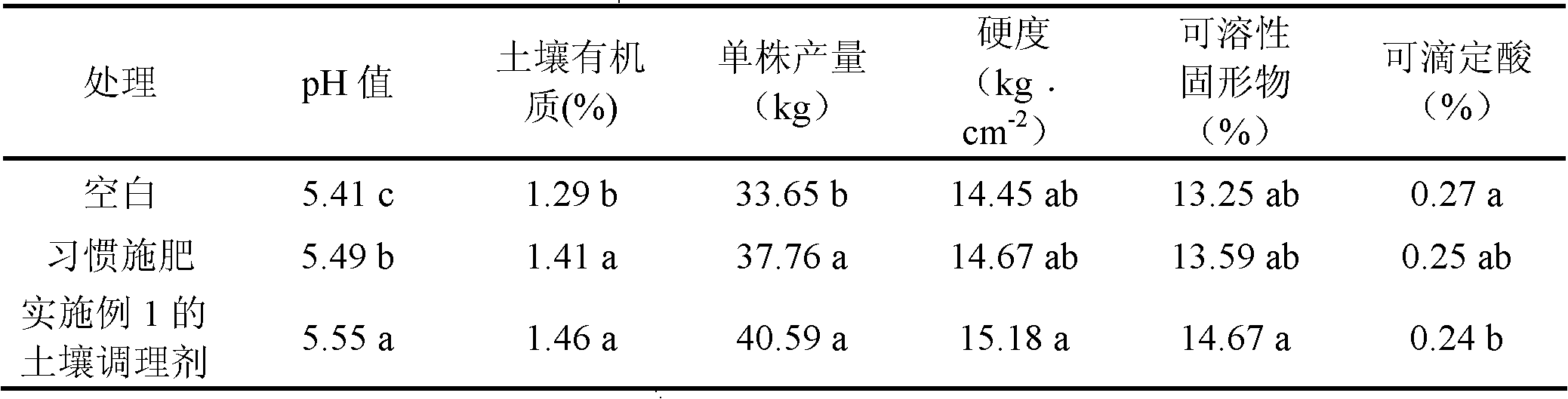

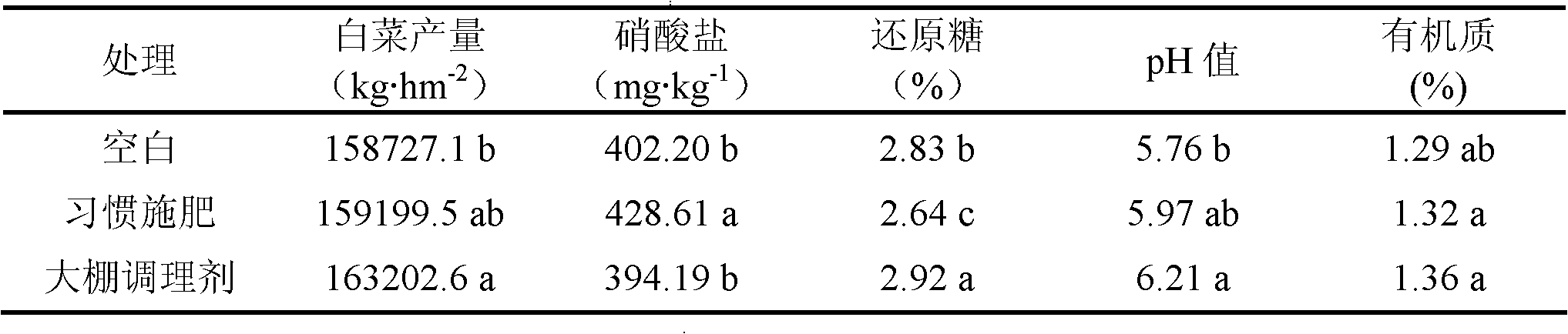

Embodiment 1

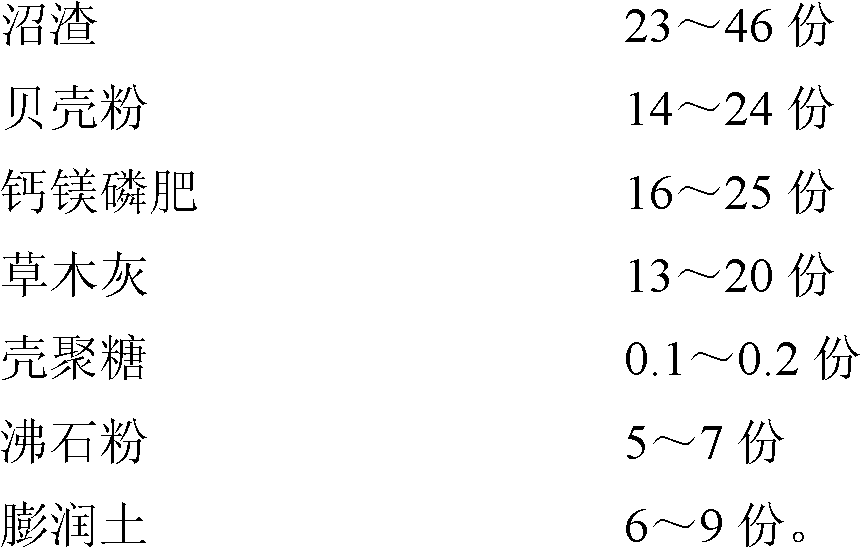

[0059] Embodiment 1: organic environment-friendly type soil conditioner, raw material component is as follows:

[0060] Biogas residue 24.3kg; shell powder 23kg; calcium magnesium phosphate fertilizer 18.5kg; plant ash 20kg; chitosan 0.2kg; zeolite powder 6kg; bentonite 8kg.

[0061] The preparation steps are as follows:

[0062] (1) Biogas residue pretreatment: the biogas residue with animal manure and straw as the main raw material is separated from solid and liquid, and then air-dried or dried to obtain biogas residue with a water content of 25wt%; shear and pulverize the biogas residue to fineness 0.8mm;

[0063] (2) Pretreatment of shell powder: Rinse natural scallop shells, oyster shells, green clam shells, carved clam shells, meretrix meretrix shells or mixed shells with clean water, dry them to constant weight, place them in a kiln, and heat Carry out high-temperature calcination at 960-980°C for 40-50 minutes, lower to room temperature, then grind, pass through a 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com