Adhesive composition and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

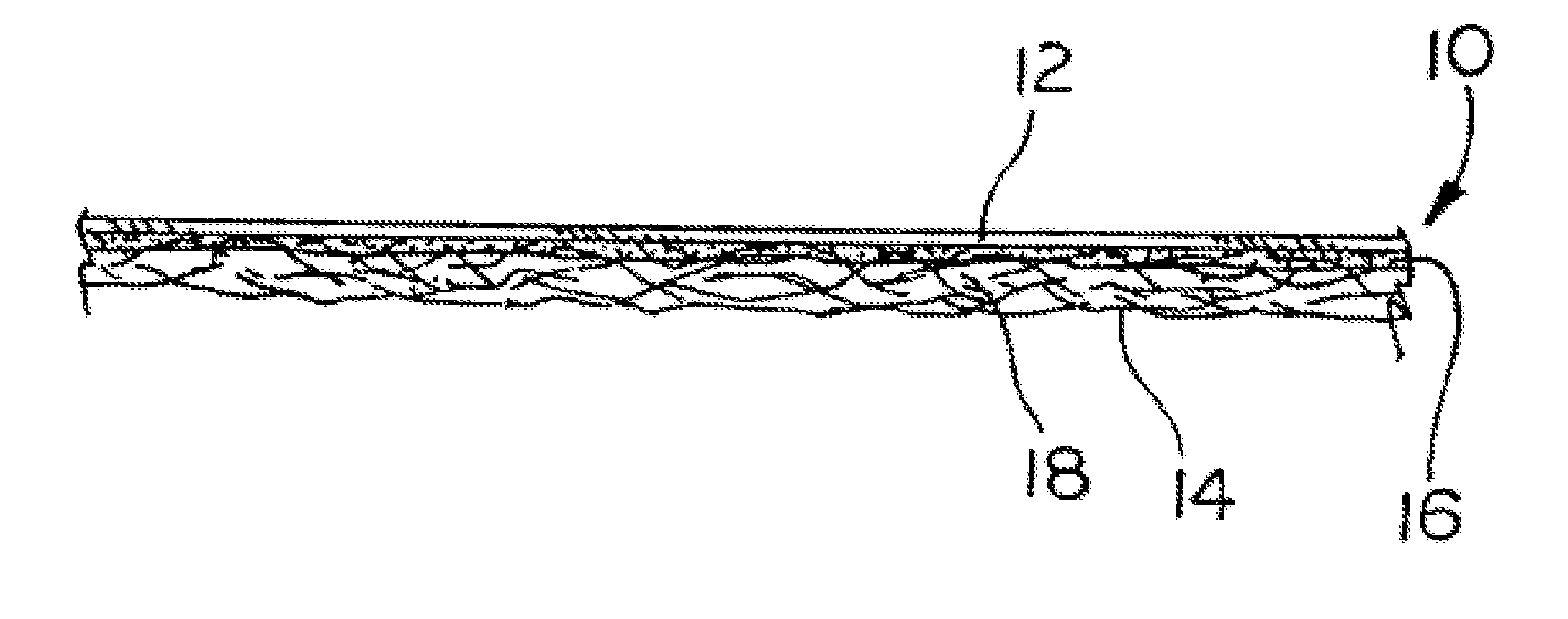

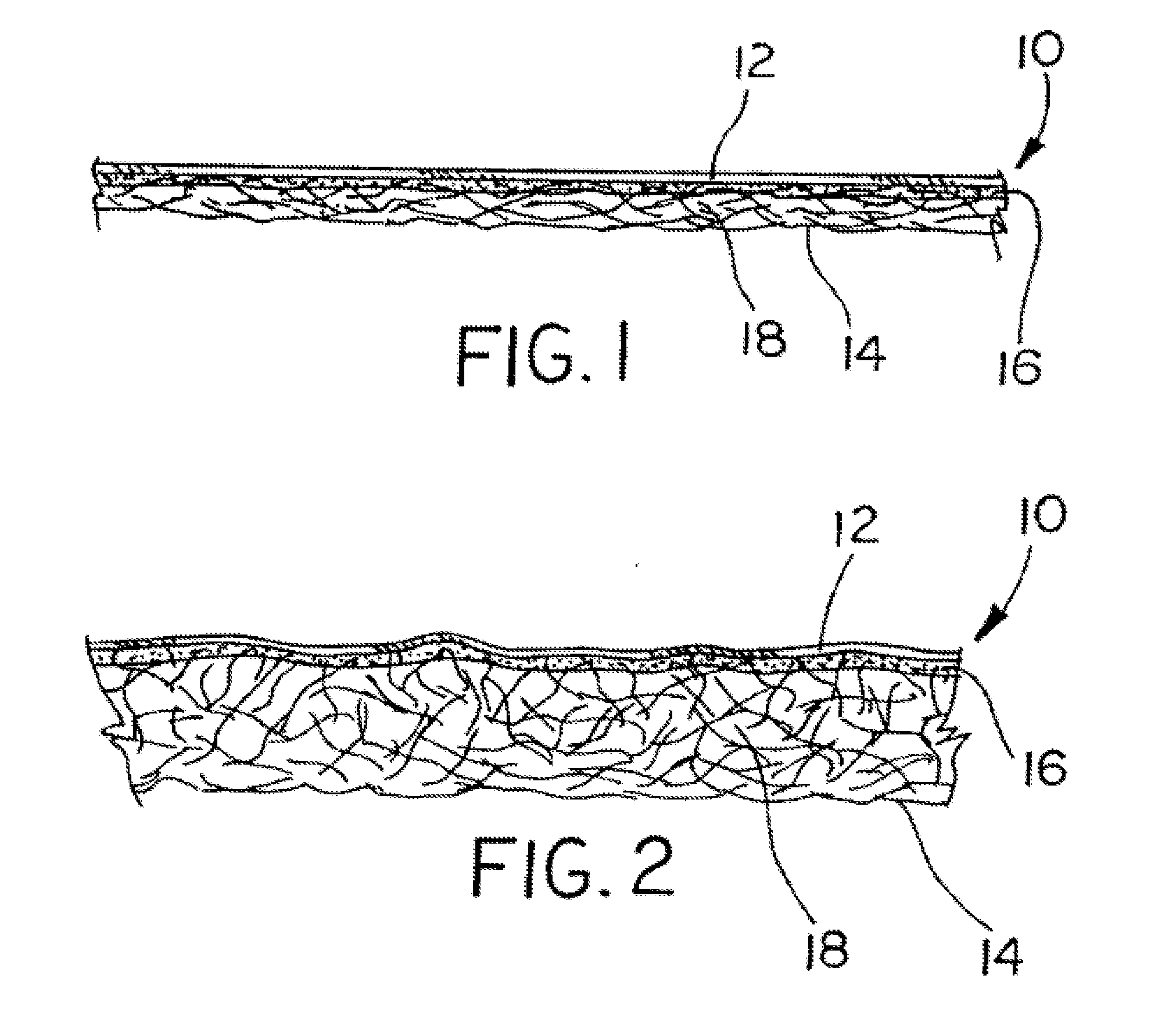

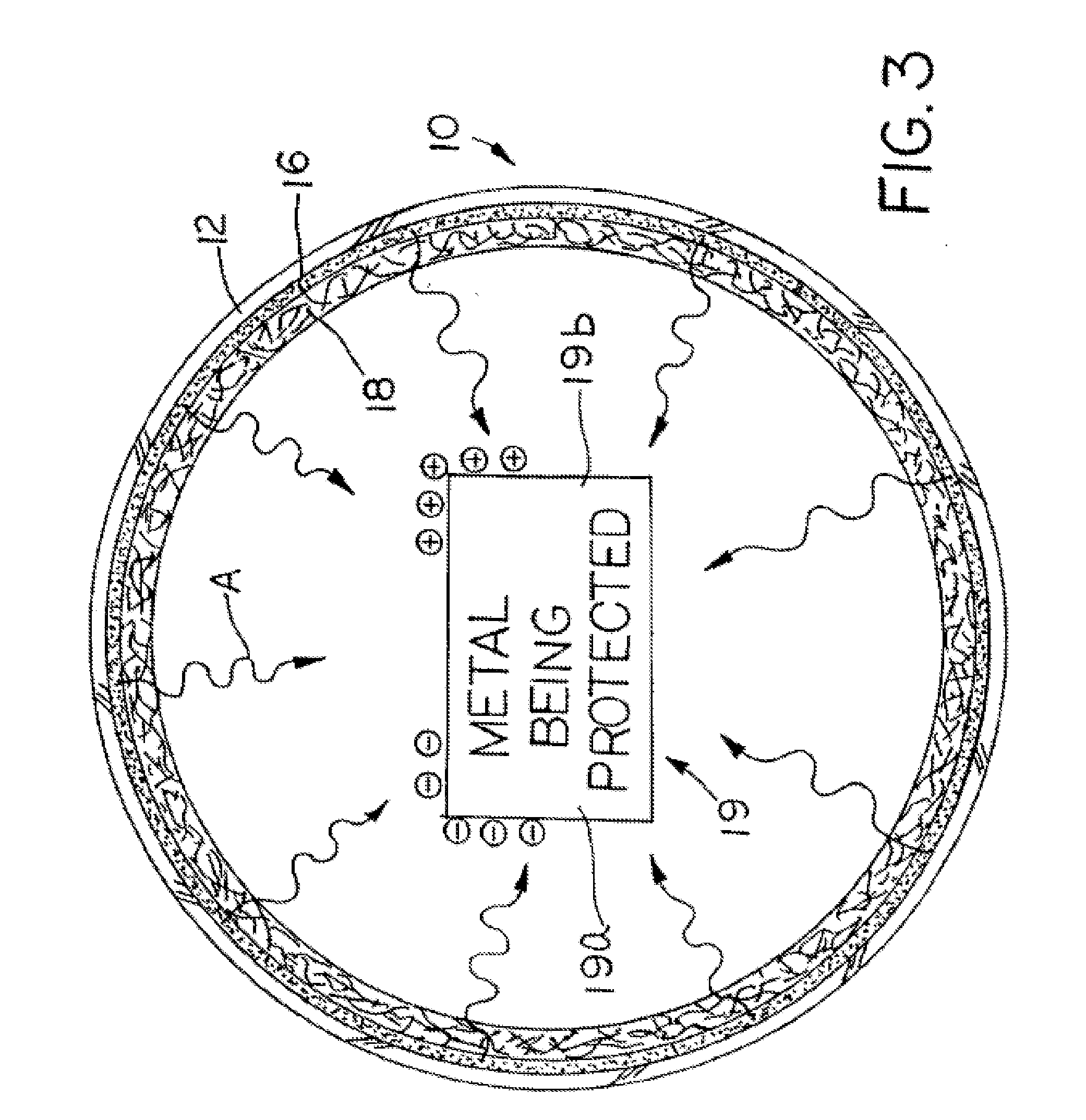

Image

Examples

example 1

[0146]Using a ZSK 30 mm twin-screw extruder—screw design A42723.001, at Aspen Research Inc. St. Paul, Minn., the initial integration of VCI(T) powder to the adhesive was improved dramatically in terms of speed, quality and uniformity. In this system the hot-melt adhesive is pumped from a drum to the 30 mm twin-screw extruder with the hose temperature at 155° C., melt temperature at 125° C. When the adhesive reached to the barrels the temperatures were lowered to 110° C.-120° C. range which provides a safe compounding temperature for the VCI(T) powder by preventing loss of excess VCI and burning the titanate. The SEBS rubber that makes up the matrix for the original adhesive is shear sensitive. This way it allows the twin screw turn and push it through the barrel at a lower temperature without losing shear. This allows the adhesive to be at a lower temperature suitable for VCI(T) application.

[0147]In the experimental process, vapor phase corrosion powder consisted of benzotriazole, b...

example 2

VCI Trial Production #1

[0154]Commercial razor blades are placed in a closed Zip-Lock® type bag with a 6 inch by 8 inch rectangle of laminate. The laminate is prepared by adhering a non-woven fabric to a thermoplastic film with an adhesive. In controls, the adhesive contains no VCI. In the test samples, the adhesive contains VCI particles and titanate / zirconate coupling agents as described herein. The blades and laminate are held in the bag for two hours, and then ¼ inch of water is added to the bag. After addition of water, the blades are visually inspected with a 3× magnifying glass) on a periodic basis, and the extent and kind of rust are noted over time. In the table, the numbers represent % corrosion, being that fraction of the surface of the razor that is covered with rust at the noted time. The nature of the corrosion (black oxide, gray oxide, or red oxide) is also qualitatively noted.

[0155]Sample 1 in the table is an adhesive composition with Adhesive 2 with VCI but no titana...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com