Maintaining and energy-saving method for blowout stand-by boiler

A standby boiler and maintenance technology is applied in the field of maintenance during the period of industrial boiler shutdown and standby, which can solve the problems of high maintenance energy consumption, slow startup of standby boilers, and inability to meet continuous production of enterprises, so as to achieve rapid startup and reduce wall temperature difference. , good maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

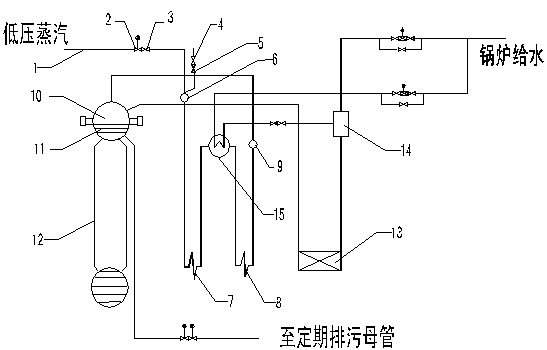

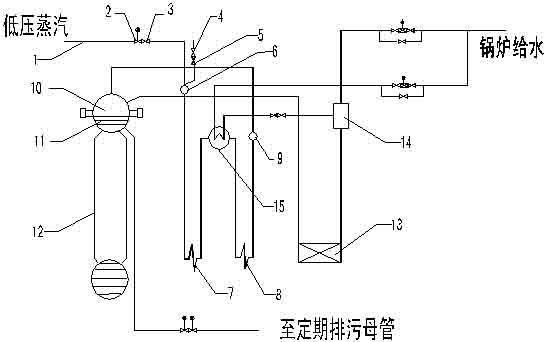

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

[0015] 1. Water side maintenance: When the boiler is running, the PH value of the boiler water is actually controlled between 10 and 12. Therefore, after the boiler is shut down for standby, keep the boiler water during operation, maintain the drum water level 11 within the range of ±30mm from the center of the drum, close all drain valves and drain valves, and perform water side maintenance.

[0016] 2. Steam side maintenance: After the boiler is shut down for standby, fully open its main steam electric valve 2 and main steam manual valve 3, close the manual emptying primary valve 5 and manual emptying secondary valve 4, and drain the water from the low-pressure steam main pipe The pipeline leads 3kg of low-pressure steam through its main steam pipe 1, the outlet header of the secondary superheater 6, the secondary superheater 7, the primary superheater 8, and the inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com