Electric power test trolley

A power test and trolley technology, applied in the direction of wheels, trolleys, measuring electricity, etc., can solve the problems of reducing the work efficiency of power maintenance personnel, moving instruments up and down, inconvenient installation, and difficulty in withstand voltage testing, and avoid cable length. Insufficient, improve the efficiency of unwinding, easy to disassemble and replace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] Embodiment A kind of electric test trolley

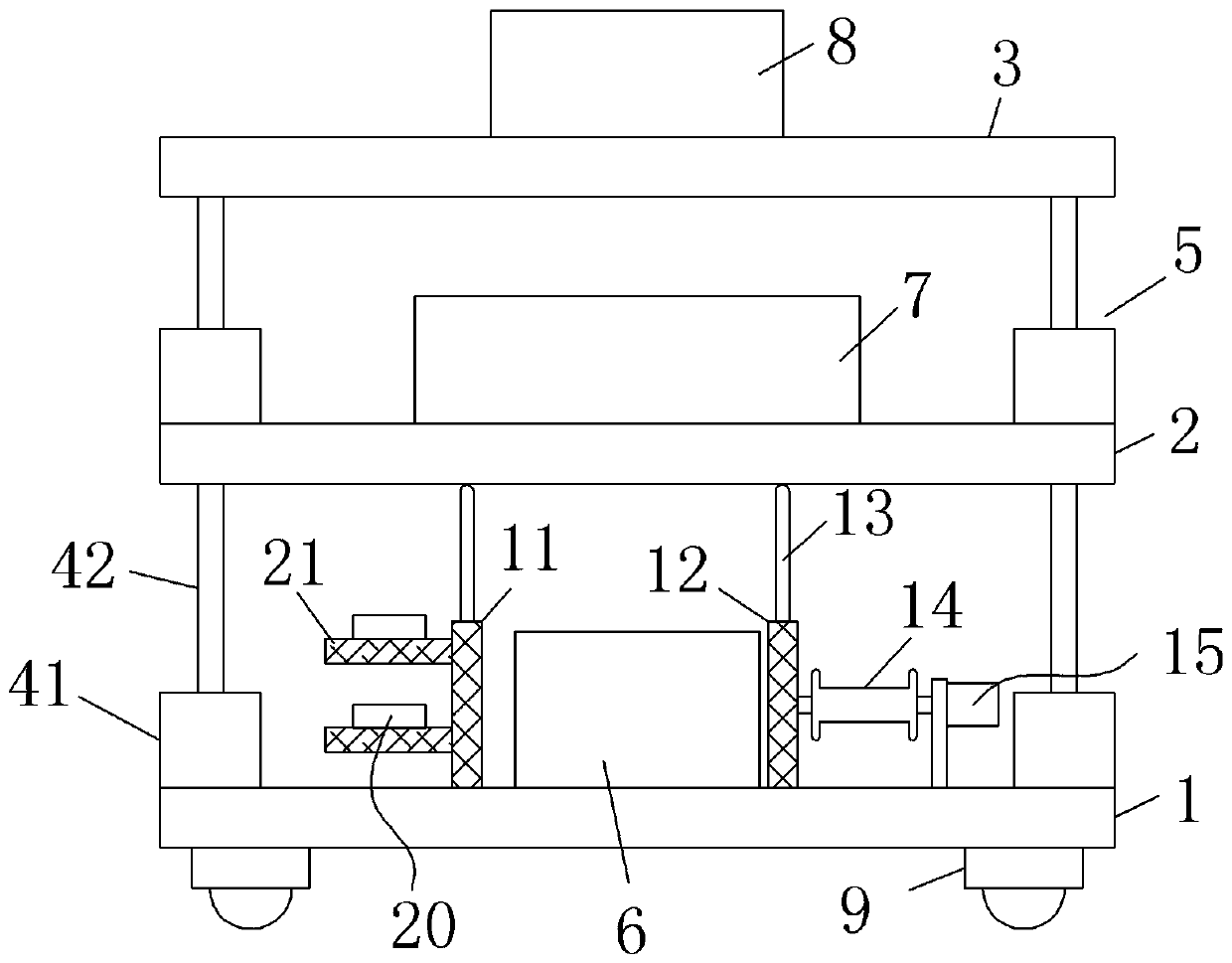

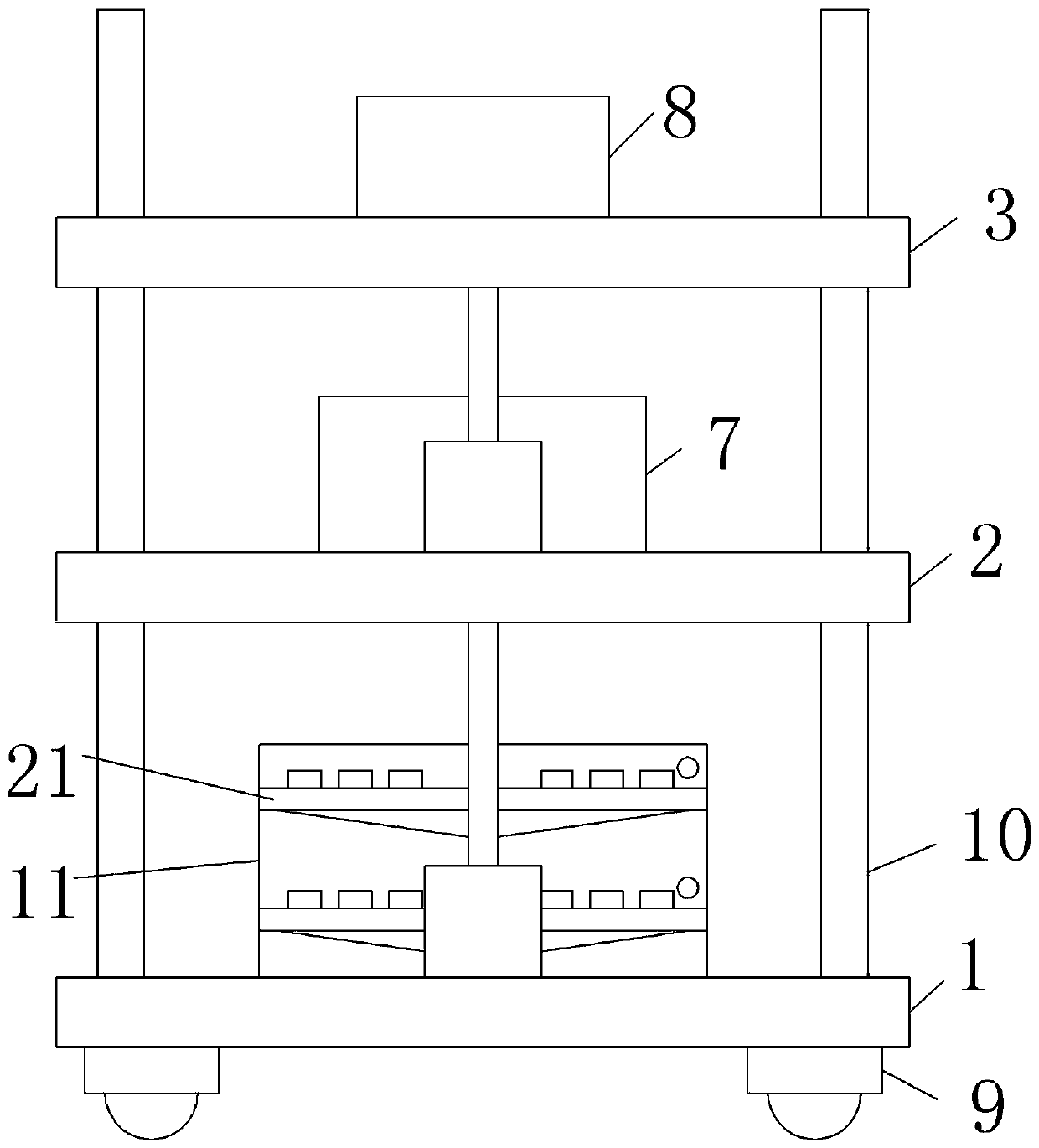

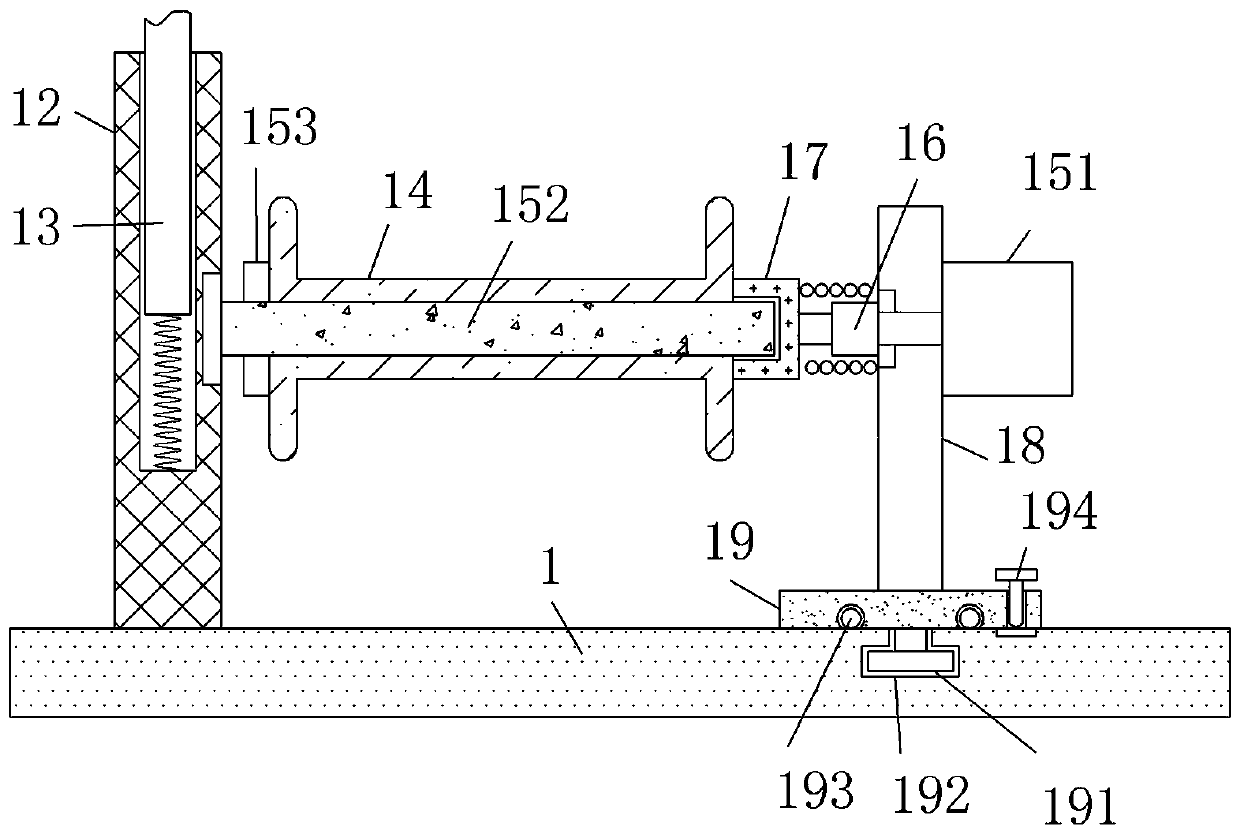

[0032] like Figure 1 to Figure 4 As shown, this embodiment includes the first support plate 1, the second support plate 2 and the third support plate 3 arranged in sequence from bottom to top, between the first support plate 1 and the second support plate 2, the second support plate 2 and the third support plate 3 are fixedly connected by lifting components, so that the height of each floor of the electric test trolley can be adjusted; the first support plate 1 is fixed with the main test equipment 6, and the second support plate 2 is fixed Auxiliary test equipment 7 is provided, and a controller 8 for controlling the main test equipment 6 and the auxiliary test equipment 7 is provided on the third support plate 3 . The controller 8 respectively controls the main test equipment 6 and the auxiliary test equipment 7 to complete the on-site detection and test of the electric safety equipment with the cooperation of cables. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com