Method for vibration-assisted induction brazing

An induction brazing and auxiliary vibration technology, which is applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as brazing seam defects and poor brazing seam density, and achieve good brazing seam density and shear strength Improvement, brazing material flow spread and the effect of rapid flow improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

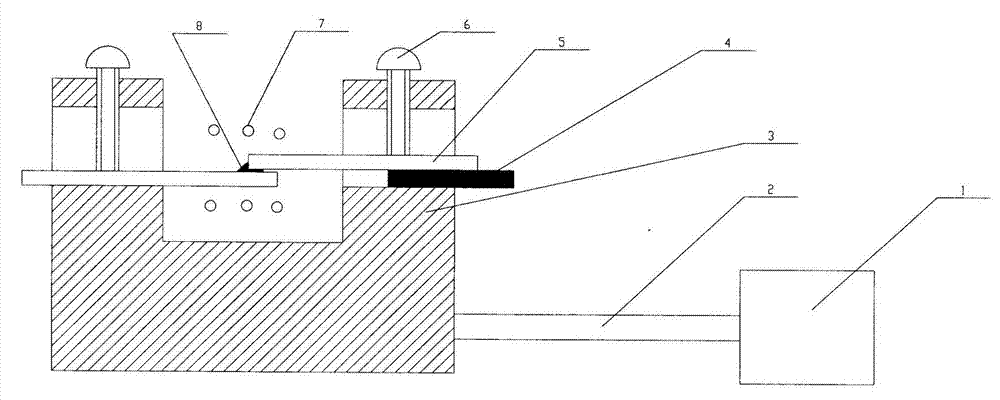

[0028] like figure 1 Shown, the method for auxiliary vibration induction brazing of the present invention comprises the steps:

[0029] (1) The clean workpiece 5 to be welded is a stainless steel plate (150mm×30mm×3mm), lap joints, and pre-set flux and copper-based powdered solder 8 at the joints;

[0030] (2) Pass the workpiece to be welded through the induction coil 7 and place it horizontally on the vibration table 3, cooperate with the gasket 4 with a thickness of 3mm, so that the position to be welded is in the center of the induction coil; tighten the fastening screws 6 at both ends to fix it ;

[0031] (3) Start the water-cooling system, and start the high-frequency power supply of the induction brazing machine, and heat the workpiece to be welded for 15s;

[0032] (4) The solder is melted and spread, and the mechanical vibrator is turned on for 3s, with an amplitude of 4μm and a vibration frequency of 25kHz;

[0033] (5) Stop the vibration, keep warm for 10s, let th...

Embodiment 2

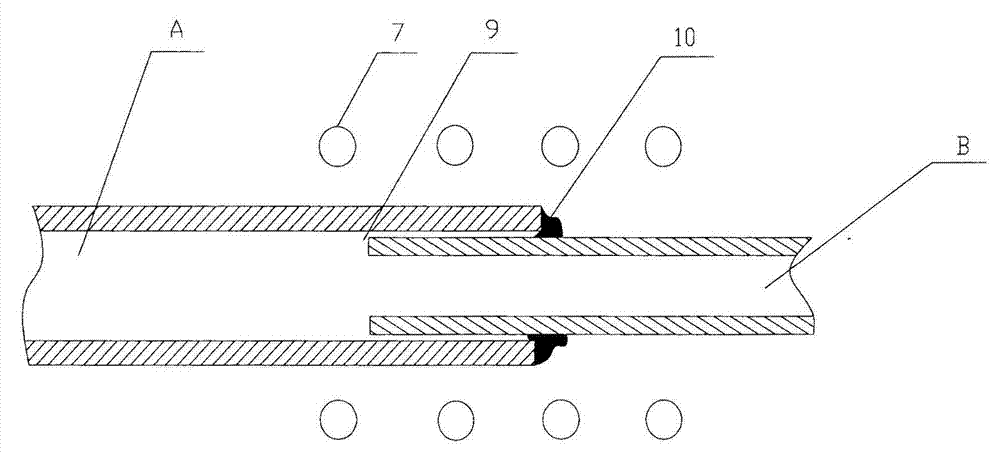

[0037] to combine figure 1 and figure 2 , changing the lap joint of the stainless steel plate into a copper pipe fitting sleeve 9, and pre-setting flux and paste copper-based solder 10 at the joint, including the following steps:

[0038] (1) The clean workpiece 9 to be welded is a socketed copper pipe fitting, in which pipe A: inner diameter 30mm, outer diameter 33mm; pipe B: inner diameter 27.5mm, outer diameter 29.5mm, pre-set flux and paste copper at the joint Base solder 10;

[0039] (2) Pass the workpiece to be welded through the induction coil 7 and place it horizontally on the vibrating table 3. The end of the tube B is fitted with a gasket 4 with a thickness of 1.5mm, so that the position to be welded is in the middle of the induction coil; tighten the fastening screws at both ends 6 fix it;

[0040] (3) Start the water cooling system, and start the high-frequency power supply of the induction brazing machine, and heat the workpiece to be welded for 25s;

[0041]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com