Composite spring type flexible clutch as well as welding method thereof

A technology of flexible couplings and composite springs, which is applied in the direction of elastic couplings, couplings, mechanical equipment, etc., can solve the problems of high technology, easy aging, low reliability, etc., and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

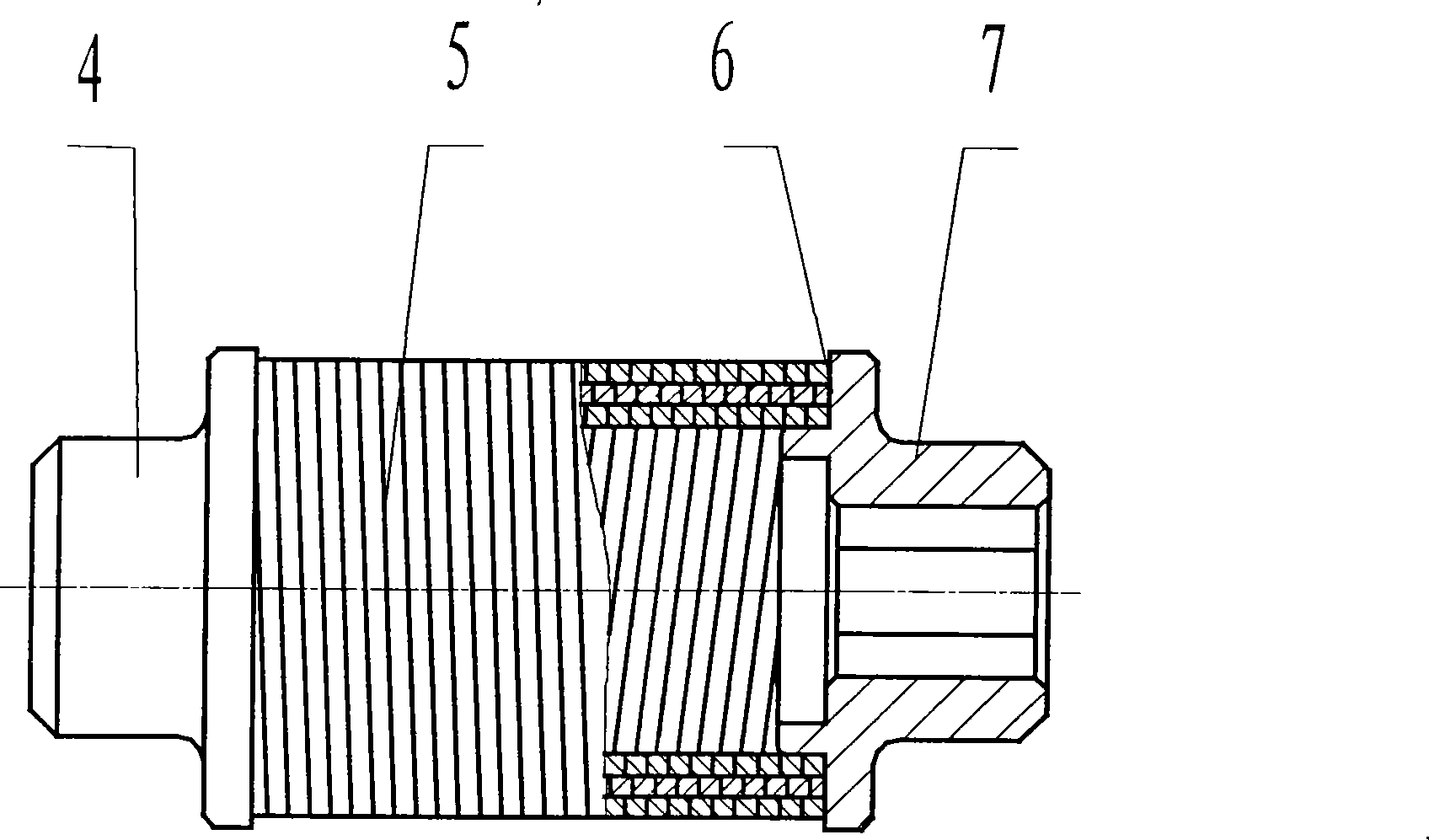

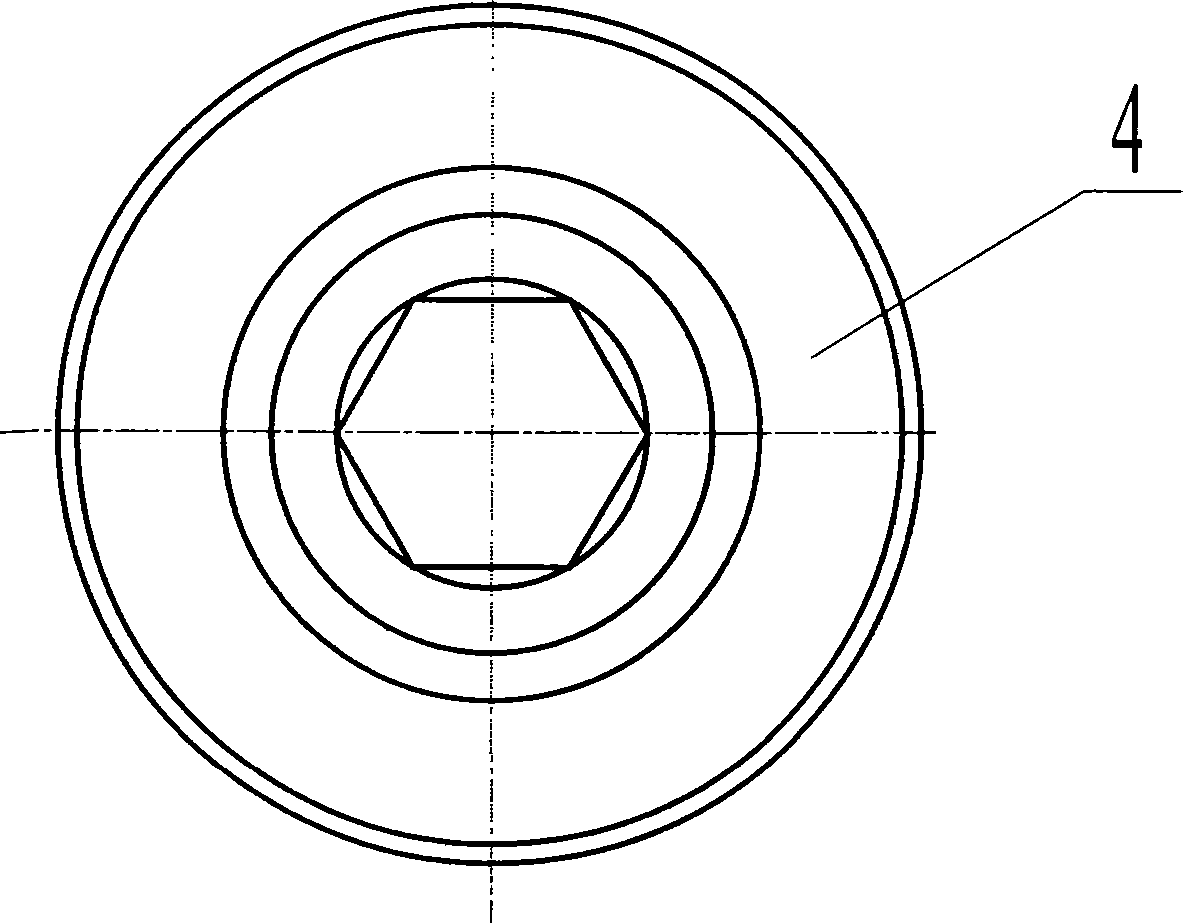

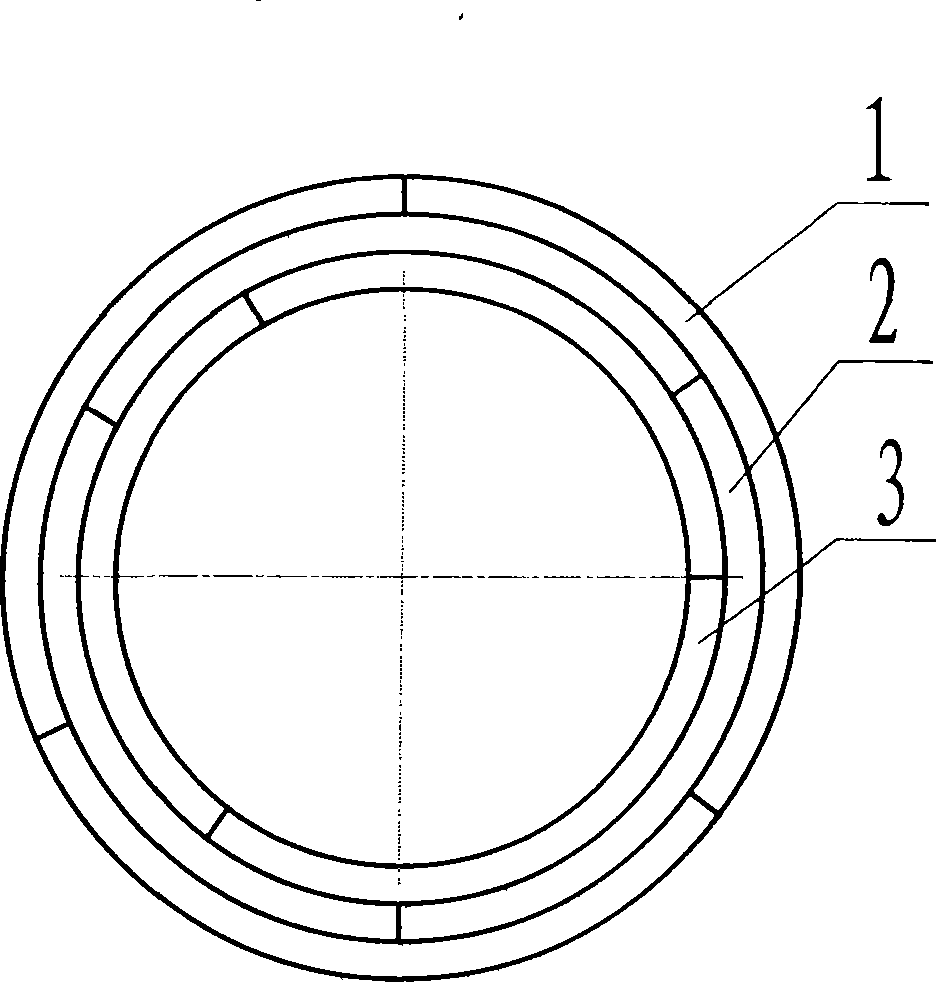

[0031] See figure 1 , figure 2 with image 3 , The composite spring 5 is composed of an inner layer of spiral spring 3, a middle layer of spiral spring 2 and an outer layer of spiral spring 1. Each layer of spiral spring is composed of three rectangular spiral springs with a rectangular cross section, and the ends of the three spiral springs are evenly divided; The direction of rotation of the spiral spring is right-handed, and the direction of rotation of the middle-layer spiral spring is left-handed; the two ends of the composite spring 5 are respectively provided with a hexagonal through hole in the center of the first half coupling 4 and the second half coupling The step 6 provided at one end of 7 can be welded.

[0032] See Figure 4 with Figure 5 , The welding method of the composite spring type flexible coupling according to the present invention has the following steps:

[0033] The first step is the preparation of the solder: a sheet of silver solder with a thickness of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com