Gas protecting means for preparing superhard abrasive material tools through induction brazing

A gas protection device and induction heating technology, applied in the direction of manufacturing tools, auxiliary devices, metal processing, etc., can solve the problems of substrate microstructure and diamond abrasive performance adverse effects, protracted production cycle, long heating and cooling time, etc., to achieve improved The effect of welding quality, welding firmness and stable chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

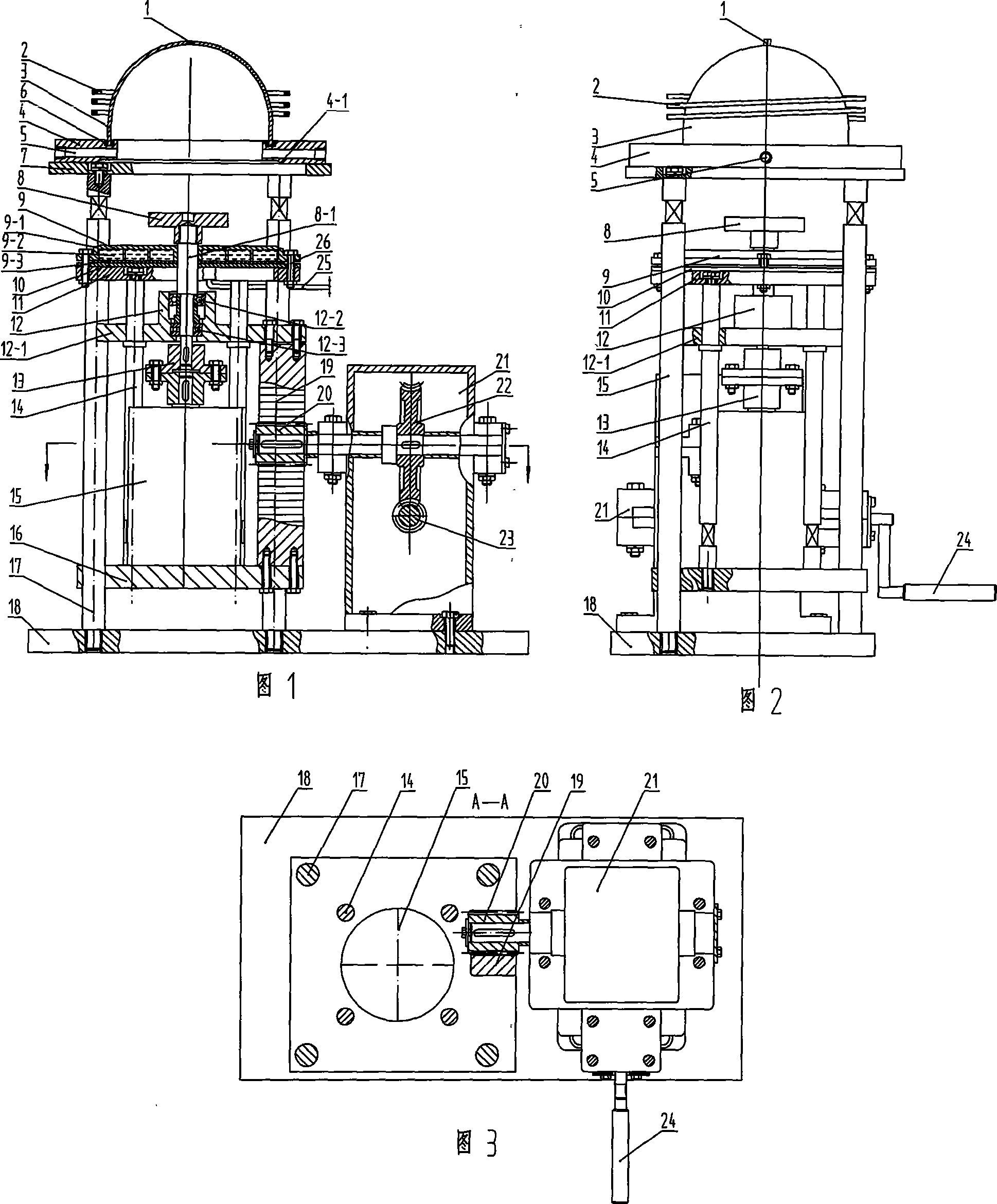

[0024] As shown in Figure 1, Figure 2, and Figure 3, a gas protection device for making superabrasive tools by induction heating brazing is characterized in that the device includes a frame, an induction heating system, a gas protection chamber, a workpiece lifting system, The workpiece rotation system has five parts.

[0025] The frame includes a base 18 , an upper fixed plate 7 and guide columns 17 ; the lower ends of the four cylindrical guide columns 17 are connected to the rectangular base 18 , and the upper ends are connected to the square upper fixed plate 7 .

[0026] The gas protection chamber includes a quartz bell jar 3, an upper sealing plate 4, and a lower sealing plate 9; the lower part is cylindrical and the upper part is hemispherical. In the groove, the high-temperature sealing grease 6 is filled in the annular groove; an exhaust hole 1 is made on the upper end of the quartz bell jar 3; a protective gas inlet 5 is made on the cylindrical surface of the cylindr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com