High-frequency induction brazed diamond drill bit

A technology of high-frequency induction brazing and diamond drills, which is applied in the fields of diamond drills (opening drills) and high-frequency induction brazing diamond drills (opening drills), which can solve the problem of insufficient holding force of material alloy binders and diamond particles falling off , Shorten service life and other issues, to achieve good heat dissipation, improve service life, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

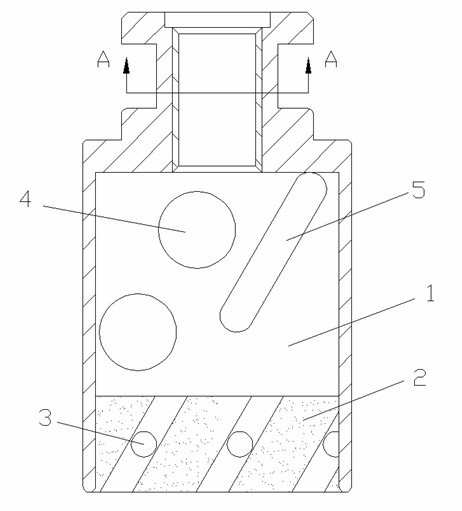

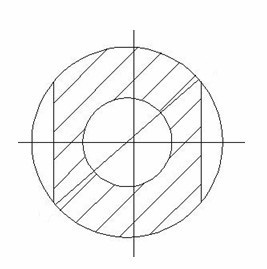

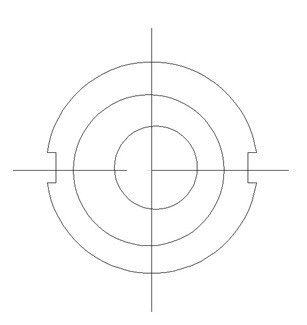

[0039] see Figure 1~3 , figure 1 It is a structural schematic diagram of the high-frequency induction brazing diamond drill bit of the present invention. figure 2 for figure 1 A-A cut-away diagram. image 3 for figure 1 top view. Depend on figure 1 , figure 2 and image 3 It can be seen that the high-frequency induction brazing diamond drill bit of the present invention comprises a drill bit matrix 1, and the composition of the drill bit matrix alloy is: 65 manganese steel and WC powder; There are only three, and there are three symmetrically on the other side of it) the first circular heat dissipation flute 3 with a diameter of 4mm, the second circular heat dissipation flute 4 with a diameter of 12mm, and two lengths of 29.2 mm and a third heat-dissipating flute 5 with a width of 4.7 mm; two layers of diamond particles 2 are brazed by high-frequency induction on the surface of the drill bit base body 0-15 mm away from its lower edge (the first brazing layer is 40 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com