Previous particle boundary precipitation preventable high-temperature alloy powder hot isostatic pressing process

A high-temperature alloy and original particle technology, which is applied in the field of static pressure process and powder metallurgy superalloy components, can solve the problems of increasing the manufacturing cost of powder superalloy, achieve the effect of improving utilization rate, reducing manufacturing cost and shortening the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The composition of the alloy is shown in Table 1:

[0037] Table 1. Alloy composition of GH4169G

[0038] Cr

Mo

Al

Ti

Nb

C

B

P

Ni

Fe

19.3

2.98

0.5

1.04

4.94

0.031

0.008

0.023

53.5

margin

[0039] In this embodiment, argon gas atomization is used to prepare the powder of the alloy, and the powder with a size below 105 microns is packed into a stainless steel sheath, and hot isostatic pressing is performed after vacuum degassing. The following process system (A) was selected for this alloy:

[0040] In the first stage, the temperature and pressure are increased with the furnace, 1245 ° C / 150 MPa / 0.5 hours, and cooled with the furnace after completion;

[0041] The second stage heat preservation process, 1110°C / 150MPa / 4 hours, cool to room temperature with the furnace.

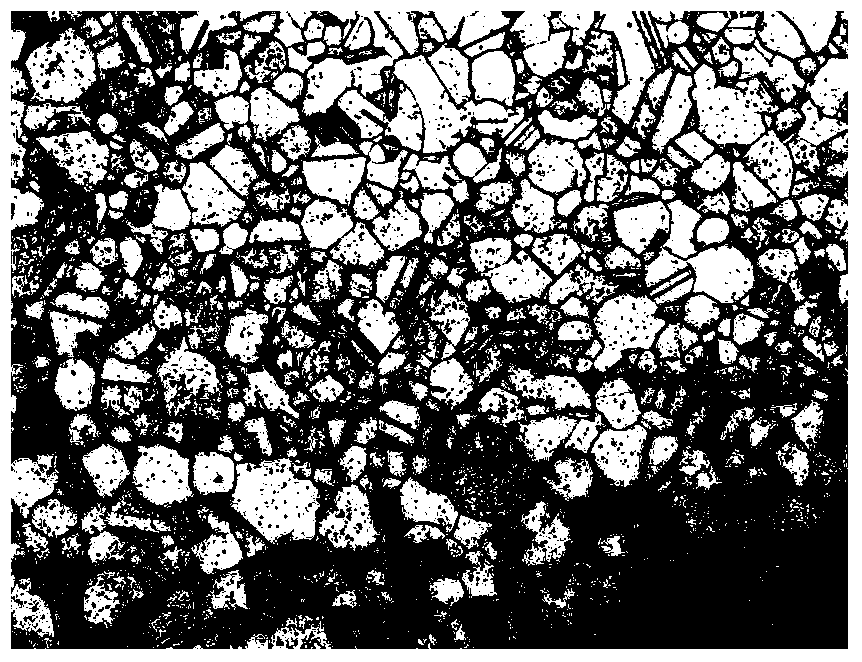

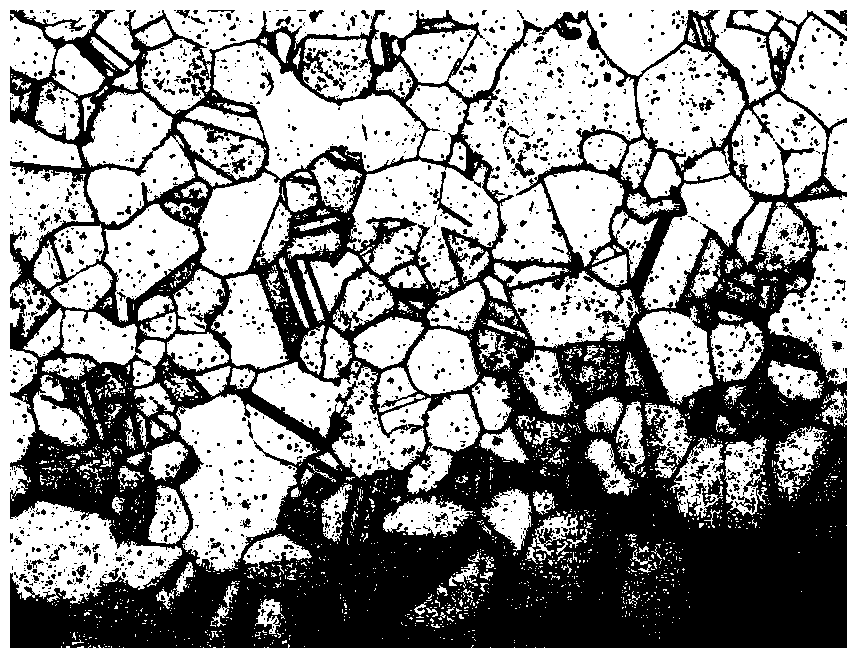

[0042] The hot isostatic pressing temperature of the first stage of the system is higher than the Laves p...

Embodiment 2

[0047] The difference from Example 1 is that the temperature in the first stage of this embodiment is above the solidus line of the alloy, and more liquid phases will be formed during the hot isostatic pressing process, so the temperature in the second stage increases accordingly, so that Ensure that the Laves phase formed after cooling in the first stage can be fully eliminated.

[0048] In this embodiment, argon gas atomization is used to prepare the powder of the alloy, and the powder with a size below 105 microns is packed into a stainless steel sheath, and hot isostatic pressing is performed after vacuum degassing. The following process system (B) was selected for this alloy:

[0049] In the first stage, the temperature and pressure are increased with the furnace, 1265 ° C / 150 MPa / 0.5 hours, and cooled with the furnace after completion;

[0050] The second stage of heat preservation process, 1140 ° C / 150 MPa / 4 hours, cooled to room temperature with the furnace. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com