Steel sheet for hot press forming having excellent heat treatment and impact property, hot press parts made of it and the method for manufacturing thereof

A technology of hot-rolled steel sheets and steel sheets, which is applied in the field of hot-formed steel sheets, can solve problems such as difficulty in controlling the concentration of the coating solution, and achieve the effects of increased yield strength, reduced weight, and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

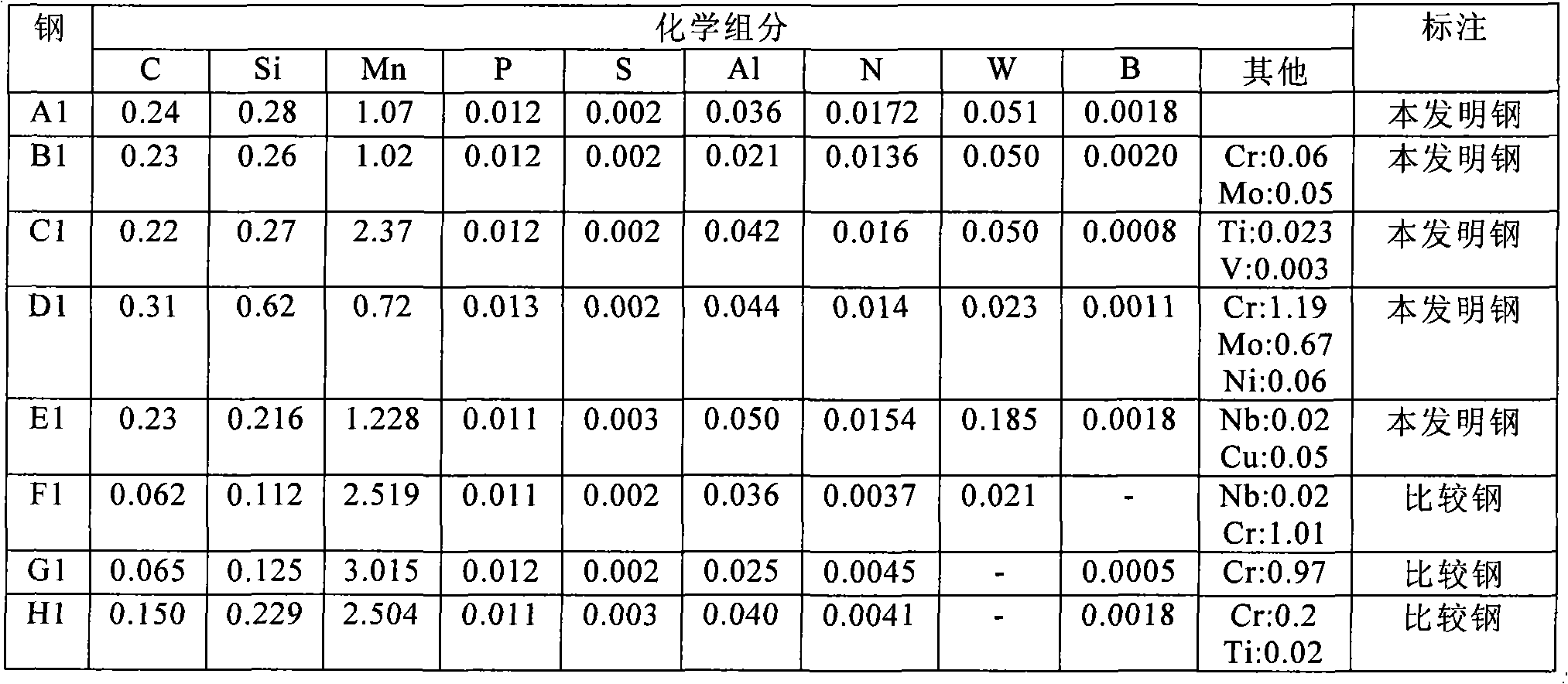

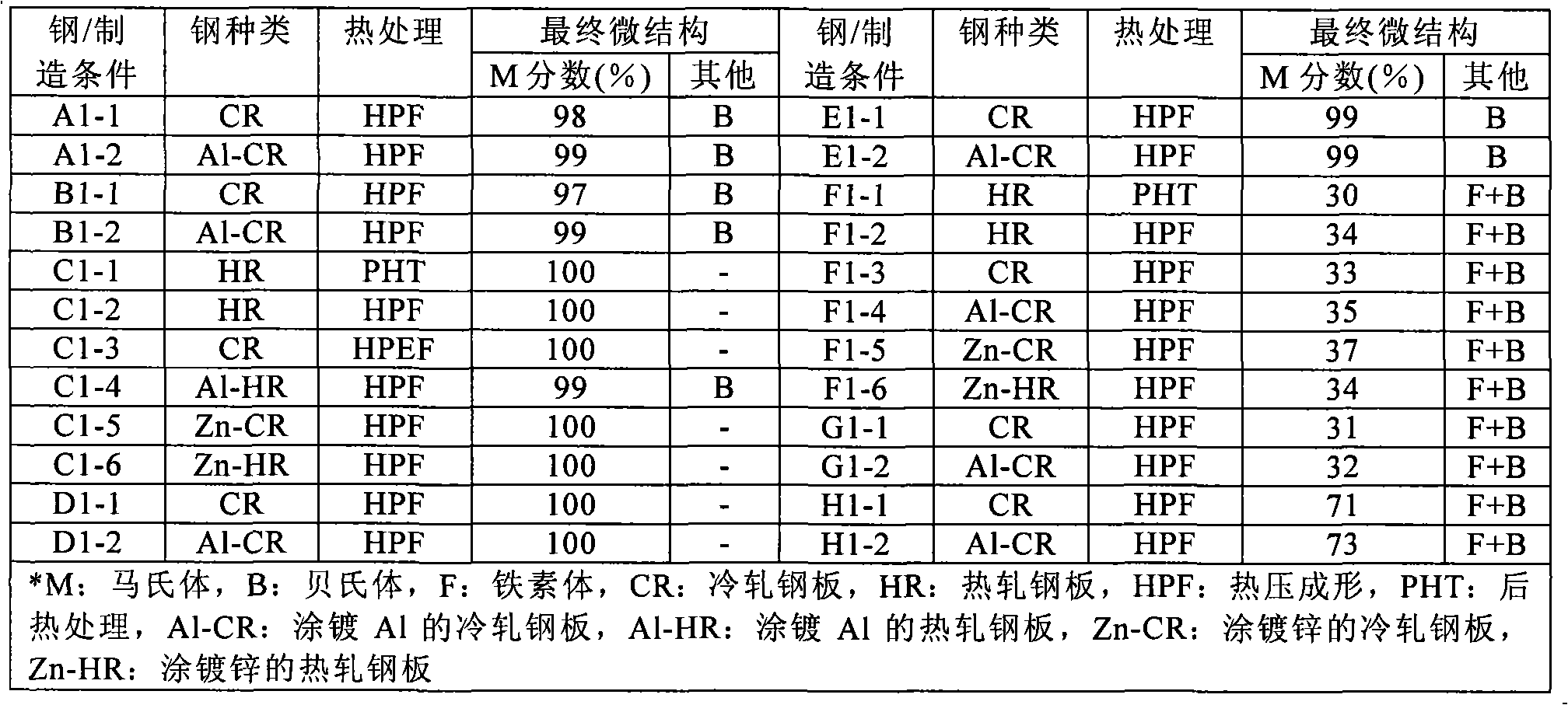

[0097] First, steel slabs having the compositions shown in Table 1 were manufactured. The steel slab is reheated at 1,150-1,250°C for 1 hour, hot rolled and coiled. Hot rolling is done at 850-950°C and coiling is done at 650°C. The parts of the hot-rolled steel sheets were pickled and cold-rolled at a reduction ratio of 50%, to manufacture cold-rolled steel sheets.

[0098] Hot-rolled and cold-rolled steel sheets are galvanized in the following manner. The steel plate was annealed at 800°C, slowly cooled to 650°C at a rate of 3°C / s, cooled to 550°C at a rate of 7°C / s, and continuously annealed at an overaging temperature of 460°C. Then, the annealed steel sheet was hot-dip galvanized for 5 seconds to manufacture a hot-dip galvanized steel sheet.

[0099] On the other hand, the hot-rolled steel sheet and the cold-rolled steel sheet were coated with aluminum in the following manner. The cold-rolled steel sheet is degreased, pretreated, preheated in a non-oxidizing furnace at...

Embodiment 2

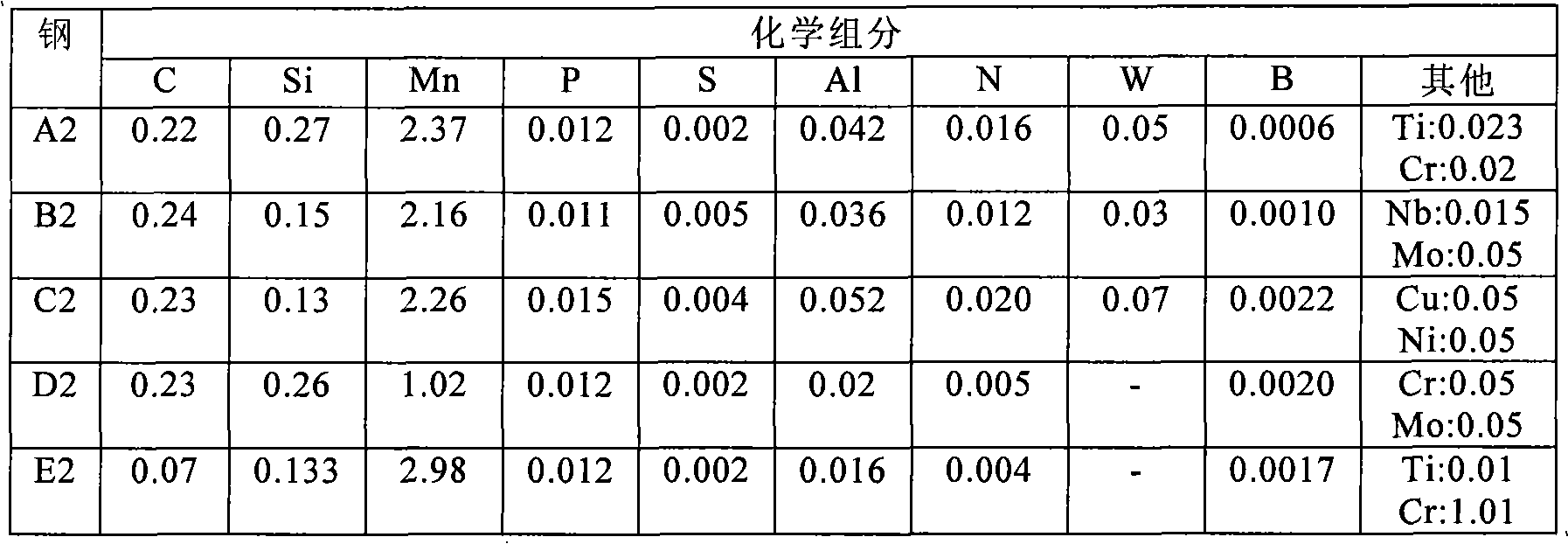

[0113] First, steel slabs having the compositions shown in Table 4 were produced. The steel slabs are dissolved under vacuum, heated in a furnace at a temperature of 1,150-1,250°C for an additional hour, and hot-rolled and coiled. Hot rolling is done at 850-950°C and coiling is done at 650°C. Hot-rolled steel sheets are pickled and cold-rolled at a reduction ratio of 50%. The cold-rolled steel sheet is annealed at 800°C and continuously annealed at an overaging temperature of 400°C.

[0114] Then, the annealed steel sheet is heated to 460°C, hot-dip galvanized for 5 seconds, alloyed at 500°C for 10 seconds to alloy the coating, and cooled to room temperature to produce an alloyed hot-dip galvanized steel sheet. Then, the coated steel sheet was heated to each temperature shown in Table 5 at a speed of 10° C. / sec, further heated in this temperature range for 5 minutes, transferred to a mold, and processed in the mold. Immediately after finishing the processing, the finished s...

Embodiment 3

[0126] First, steel slabs having the compositions shown in Table 6 were produced. The steel slabs are dissolved under vacuum, heated in a furnace at a temperature of 1,150-1,250°C for an additional hour, and hot-rolled and coiled. Hot rolling is done at 850-950°C and coiling is done at 650°C. Hot-rolled steel sheets are pickled and cold-rolled at a reduction ratio of 50%. The cold-rolled steel sheet is annealed at 800°C and continuously annealed at an overaging temperature of 400°C.

[0127] This cold-rolled steel sheet was coated with Al in the following manner. The cold-rolled steel sheet is degreased, pretreated, preheated in a non-oxidizing heating furnace at 700°C, and heat-treated in a reducing atmosphere of nitrogen and hydrogen. At this time, heat treatment is performed at a temperature of up to 820°C. The steel plate after the heat treatment was cooled and immersed in the coating solution at 680°C. The coating solution contained 8.5% Si, 2.4% Fe and the balance A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com