Tough ultra-strength stainless steel and method for manufacturing the same

A technology of ultra-high strength and manufacturing method, which is applied in the field of stainless steel materials, can solve the problems of low toughness and low yield ratio, and achieve the effect of increasing yield strength, improving yield strength and improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

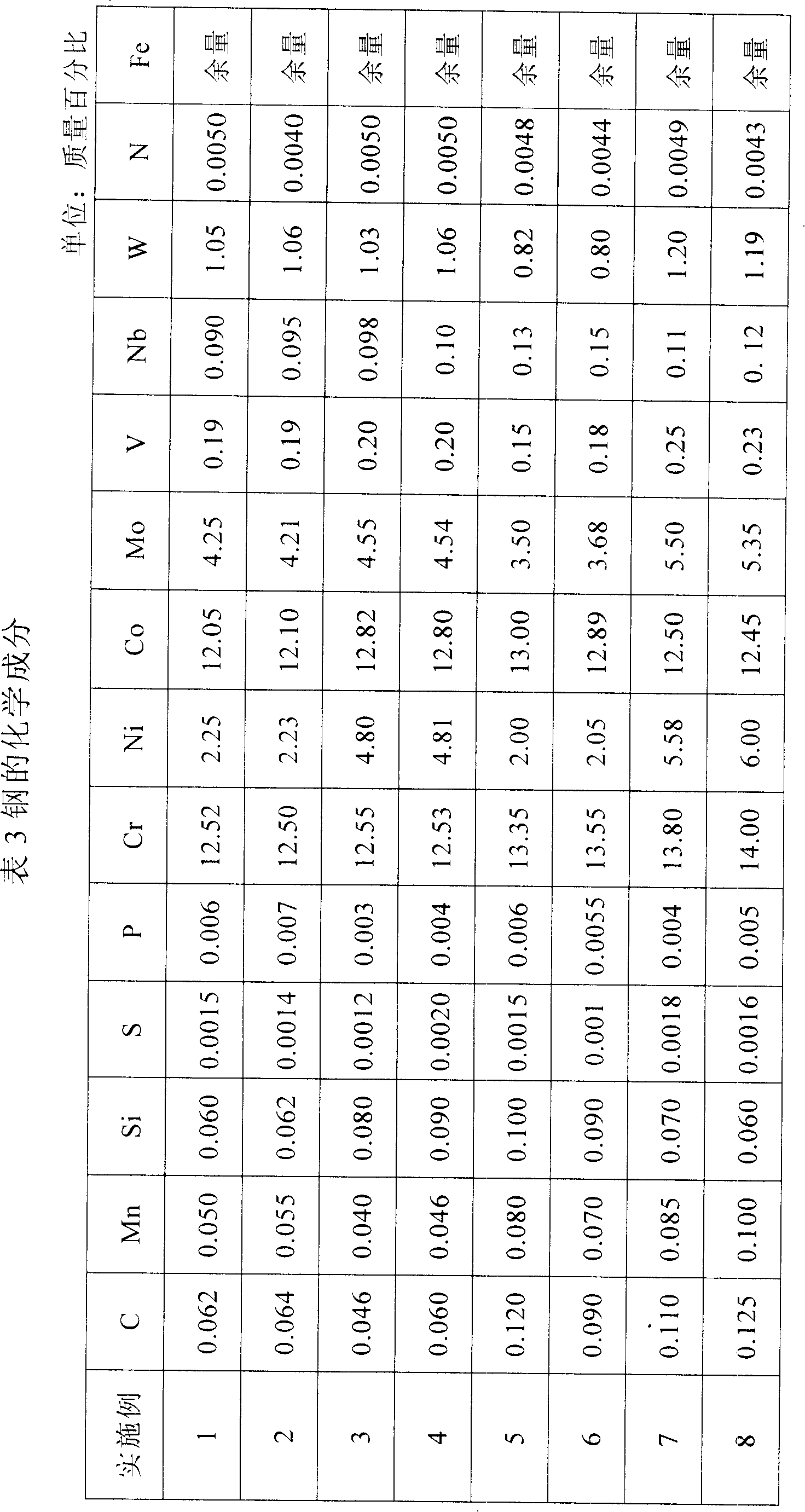

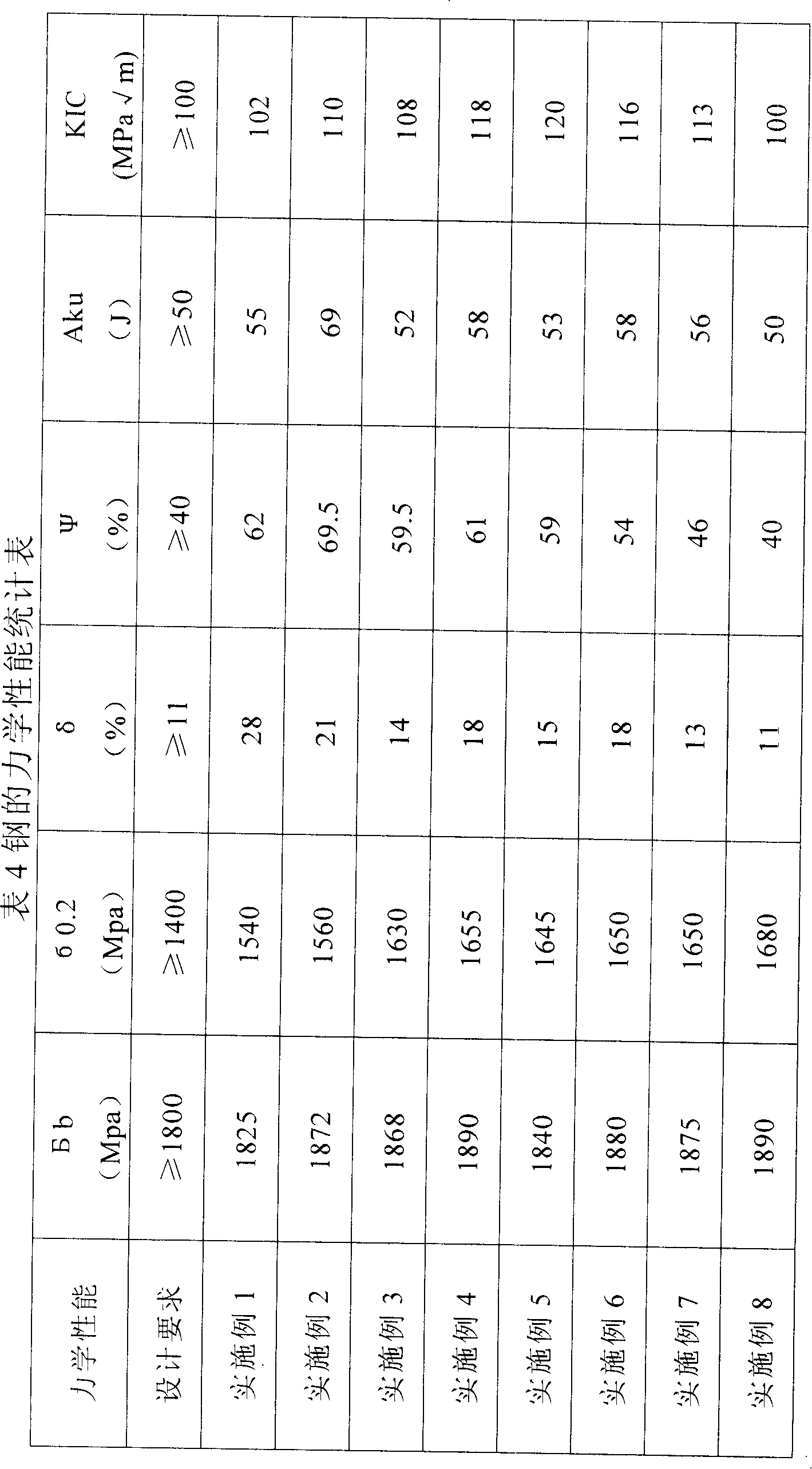

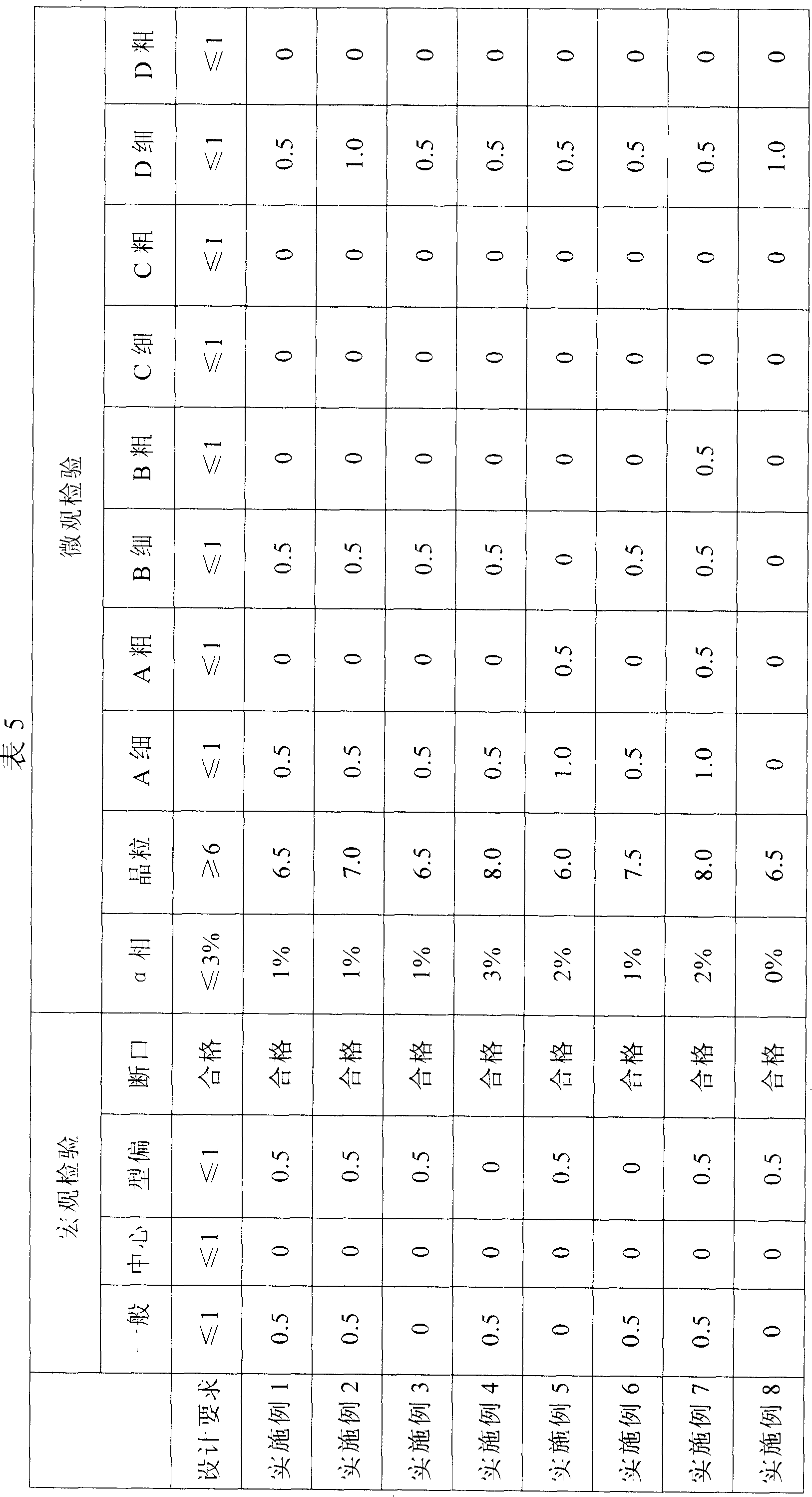

Examples

Embodiment Construction

[0050] An embodiment of the present invention is as follows,

[0051] 1. Master alloy preparation, select high-purity iron and metallic chromium, and use electric furnace + argon oxygen refining furnace (AOD) + ladle refining (LF) compound refining method to prepare master alloy as raw material for vacuum induction furnace;

[0052] 2. Vacuum induction furnace (VIM) melting electrodes,

[0053] Select high-purity metallic nickel, metallic chromium, metallic cobalt, metallic niobium or ferroniobium, metallic molybdenum or ferro-molybdenum, metallic tungsten or ferro-tungsten, and iron alumite, and select master alloys; the charge is strictly in accordance with the control target Limited allocation; pay special attention to the introduction of Si, Al, and Cu to prevent exceeding the limit; pouring Φ290 electrode, demoulding and air cooling for more than 6 hours; electrode remelting after finishing;

[0054] 3. Vacuum arc remelting (VAR) consumable remelting process

[0055] The mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com