Fishing lures having elastomeric portions

a technology of elastomeric portions and fishing lures, which is applied in the field of fishing lures, can solve the problems of reducing the service life of elastomeric materials, so as to improve the strength, toughness and fatigue resistance. the effect of high operational stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

BACKGROUND OF THE INVENTION-- Field of the Invention

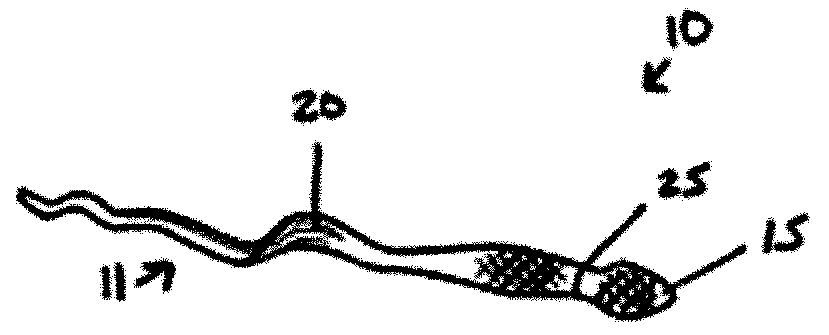

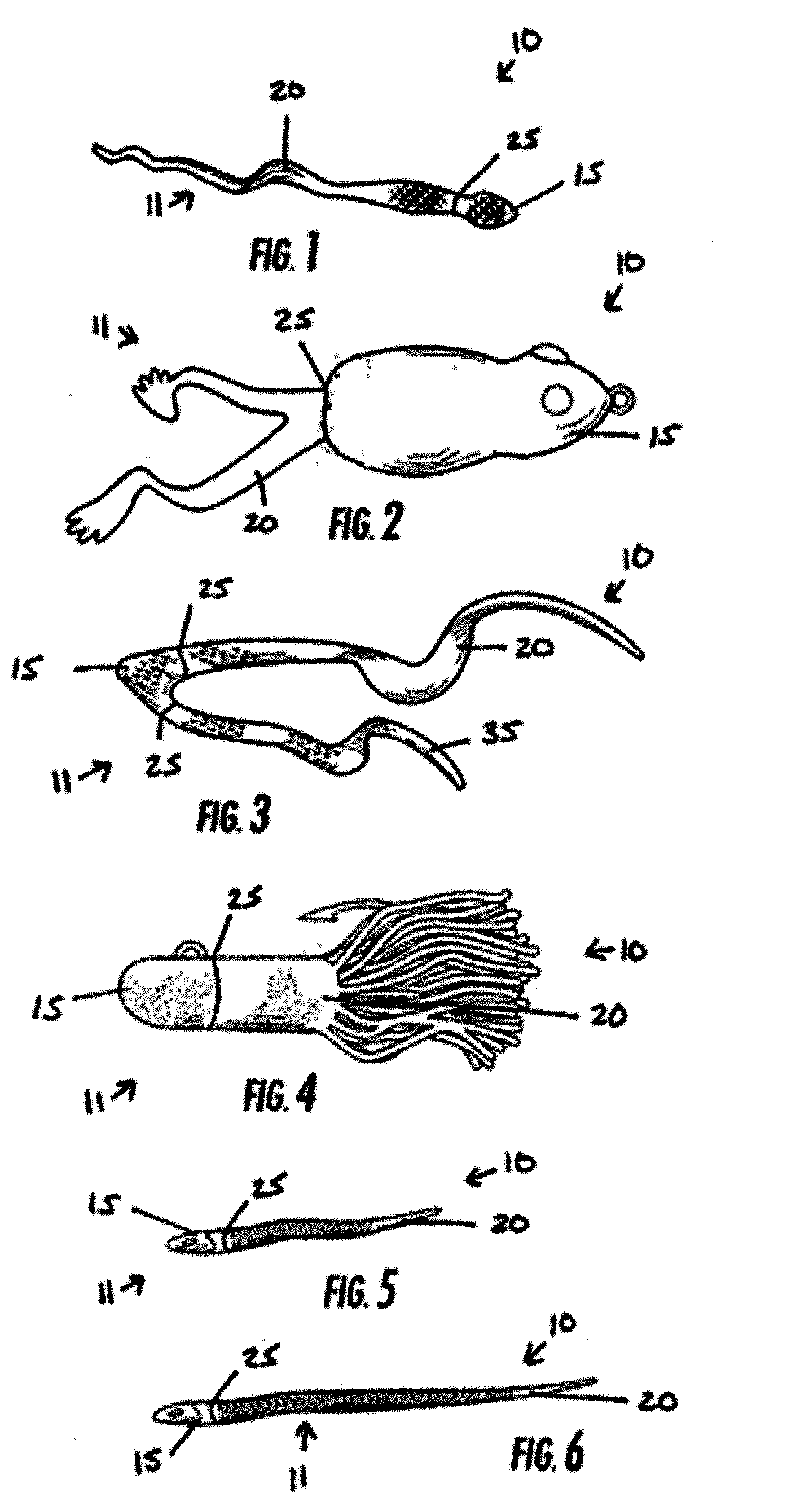

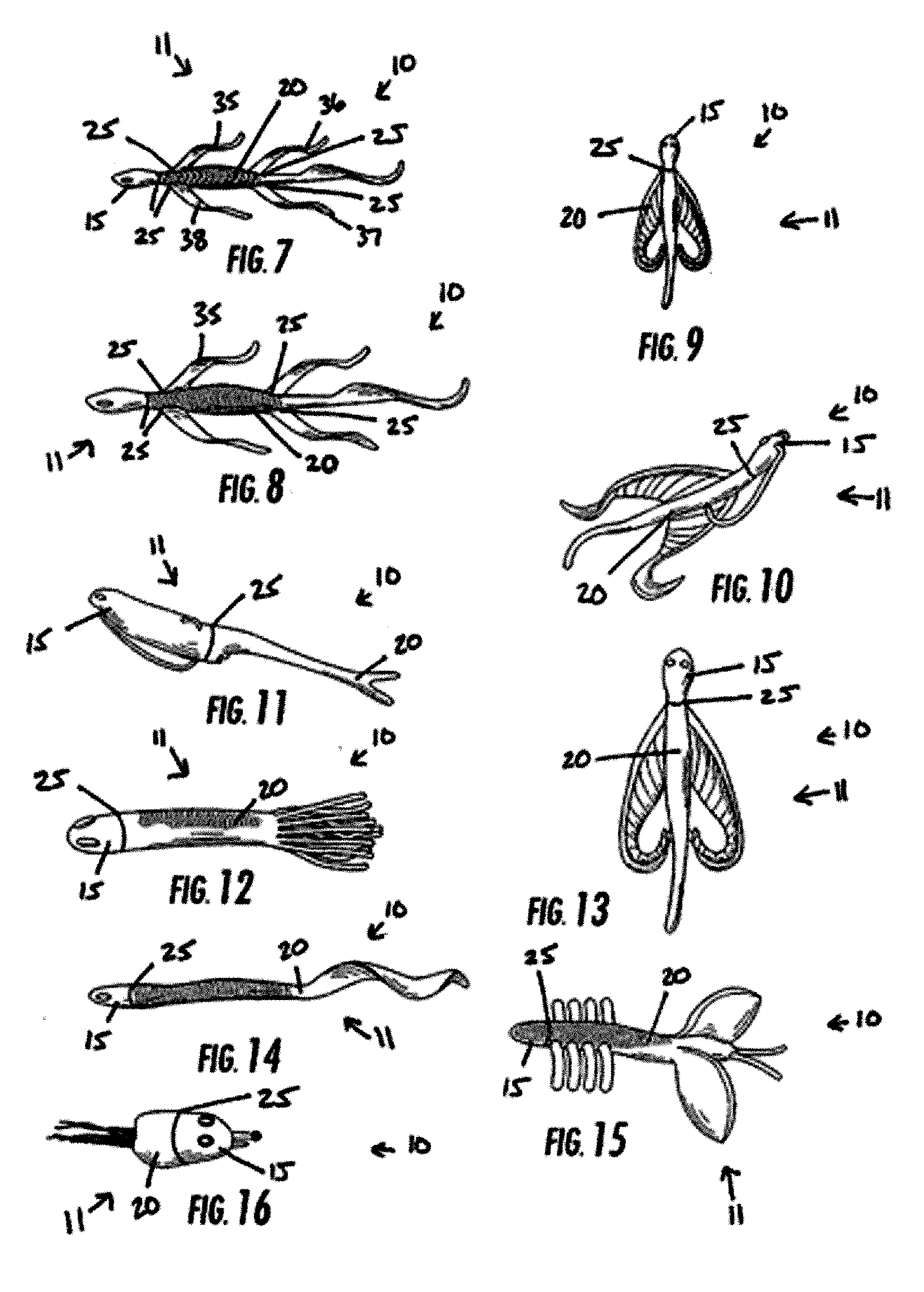

[0001] This invention relates generally to fishing lures and, more particularly, to fishing lures having elastomeric portions.

Description of Related Art

[0002] Fishermen and manufacturers of fishing lures have found elastomeric or other soft plastic materials (collectively referred to herein as “elastomeric materials”) advantageous to their craft. The elastomeric portions of the lure are soft and flexible, which gives the lure a more life-like movement (referred to herein as “live-bait action”) to attract fish. The flexibility of the elastomeric portions also allows these portions of the lure to stretch or give rather than snap or break when a fish bites down. Typically, the elastomeric portions of the lure are constructed by a relative inexpensive process of injecting a resin into a mold and hardening the resin. Therefore, the elastomeric portions of the lure can have innumerable shapes, i.e., mimic innumerable live baits, by c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com