Hybrid dust absorption environmental sanitation vehicle and hybrid sweeping environmental sanitation vehicle

A hybrid, sanitation vehicle technology, applied in road cleaning, construction, cleaning methods, etc., can solve the problems of low hydraulic transmission transmission efficiency, no dust, whether the fan exhaust air needs to spray dust, and the dust is difficult to remove.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

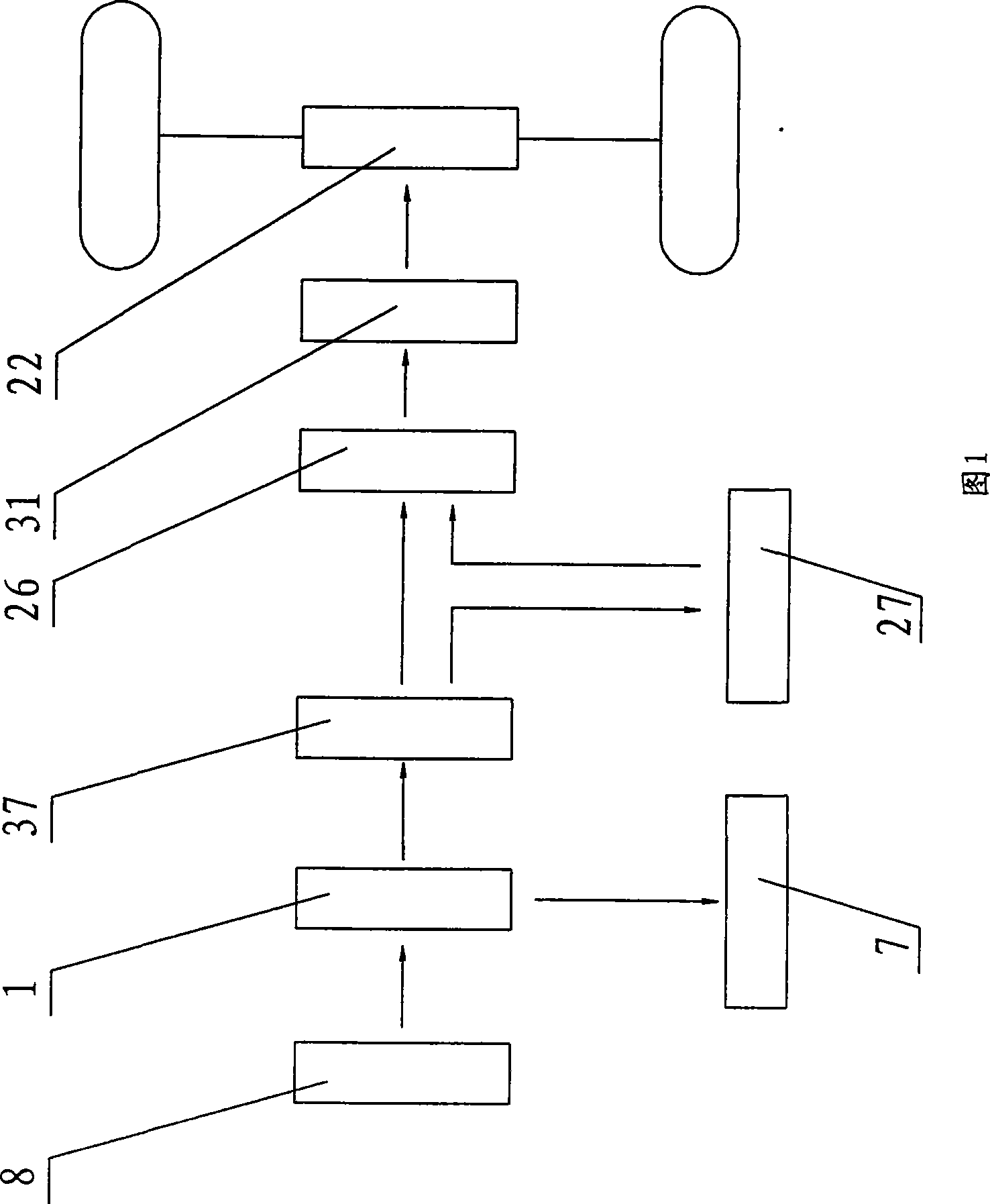

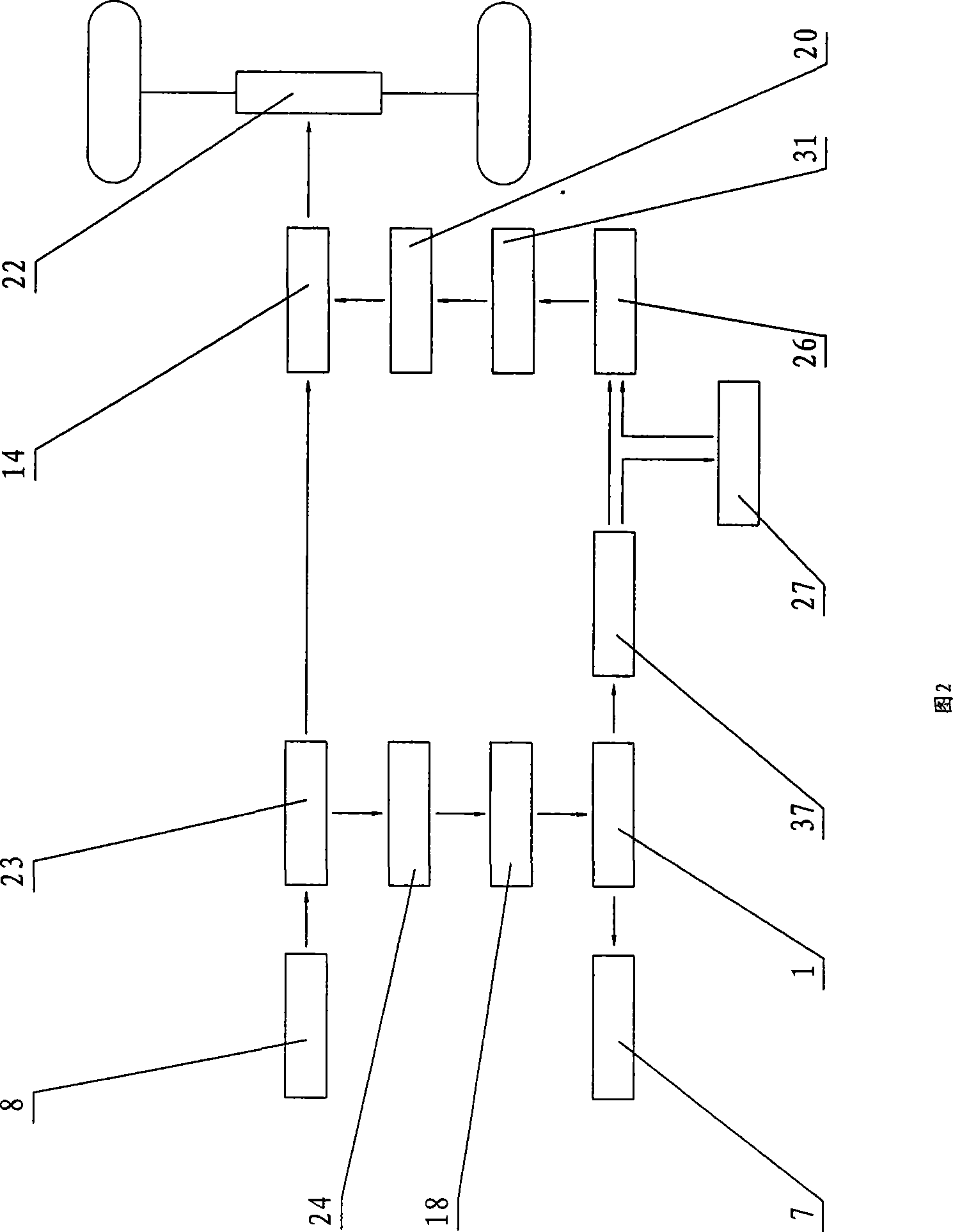

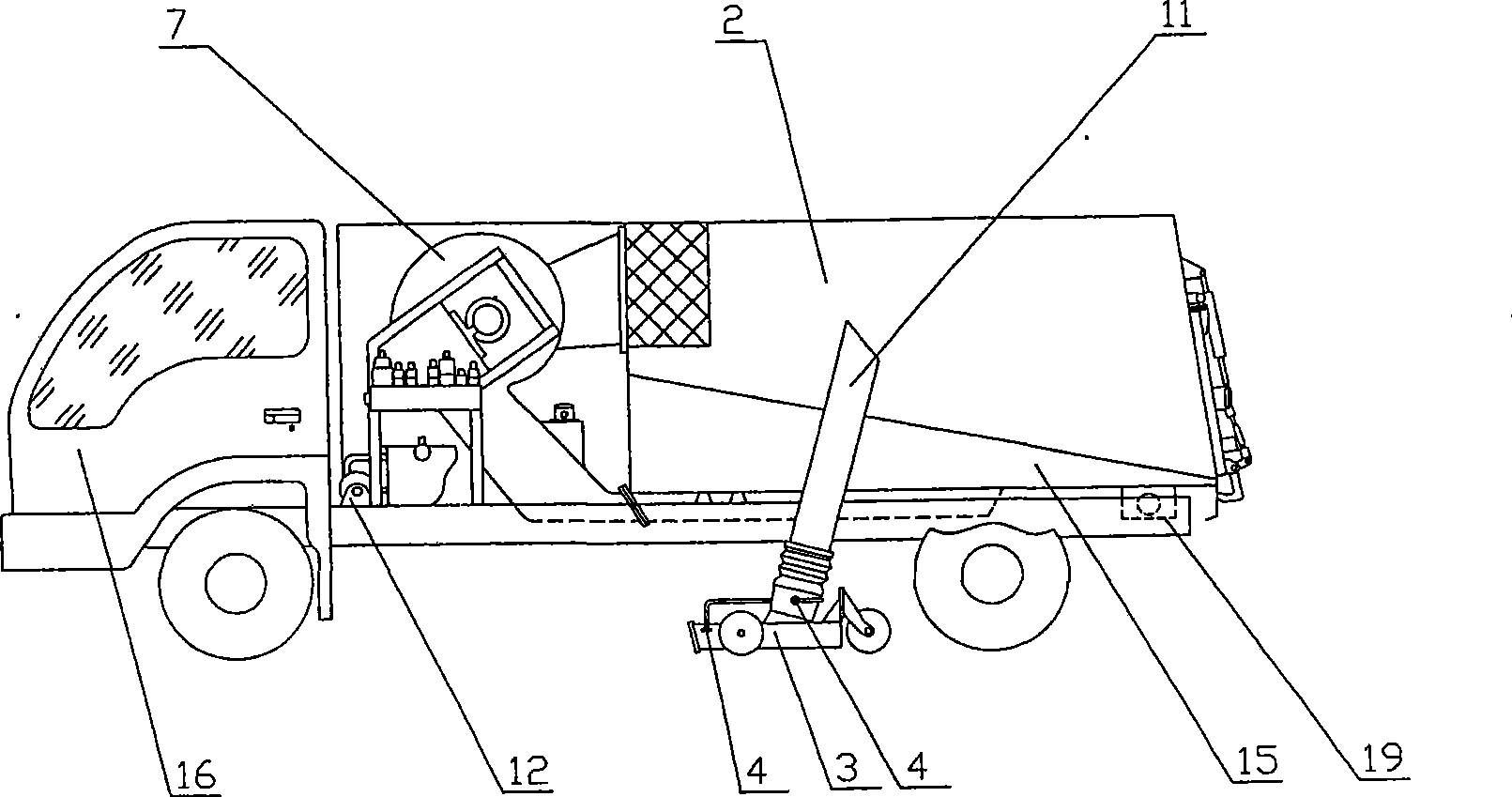

[0047] The first embodiment, a hybrid dust-collecting sanitation vehicle, as shown in Figure 1 and image 3 Shown. Figure 1 is a block diagram of the basic transmission structure of the hybrid dust-collecting sanitation vehicle of the present invention. image 3 It is a schematic diagram of the structure of a hybrid dust-collecting sanitation vehicle according to the first embodiment of the present invention.

[0048] The frame 19 is equipped with a cab 16, an engine 8, a dustbin 2, a fan 7, a suction cup 3, a suction tube 11, and a rear axle shaft 22. A suction tube 11 is installed on the suction cup 3 to communicate with the dustbin 2. The air inlet of the fan 7 is connected to the dustbin 2; the engine 8 is connected to the transmission gear transfer case 1, and the gear transfer case 1 is respectively connected to the transmission silicon rectifier generator 37 and the fan 7, and the silicon rectifier generator 37 is also connected to the battery 27 and a power converter 26, t...

no. 3 example

[0067] The third embodiment, the third embodiment is a sweep-suction cleaning and dust-collecting sanitation vehicle with a hybrid power transmission structure, which is an extension of the chassis transmission structure and dust-collecting operation structure of the second embodiment, such as Figure 5 , Figure 6 Shown. Figure 5 It is a schematic diagram of the structure of the cleaning and dust collection sanitation vehicle according to the third embodiment of the present invention. Figure 6 for Figure 5 Schematic of the top view.

[0068] On the basis of the chassis transmission structure of the second embodiment, butterfly sweeping brushes 6 are respectively installed on both sides of the frame 19; the gear transfer case 1 is sequentially connected to drive hydraulic pumps and hydraulic motors to drive butterfly sweeping brushes 6 for cleaning Or the battery 27 is connected to the DC motor to drive the butterfly sweeping brush 6 for cleaning; the suction cup 3 is installed...

no. 7 example

[0087] The seventh embodiment, a hybrid power sweeping sanitation vehicle, such as Picture 12 Shown. Picture 12 It is a schematic top view of the structure of a hybrid pure sweeping sanitation vehicle according to the seventh embodiment of the present invention.

[0088] The invention provides a hybrid sweeping sanitation vehicle, which includes a frame 19 on which an engine 8, a butterfly sweeping brush 6, a rolling brush 35, a dustbin 2, a water tank 15, a water pump 12, and a rear axle are installed The shaft 22 is mounted with a cab 16 on the frame 19, the butterfly brushes 6 are mounted on both sides of the head of the sanitation vehicle and / or on both sides of the middle of the frame 19, and the roller brushes 35 are mounted on The butterfly sweep brush 6 is placed horizontally under the frame 19 and in the middle of the sanitation vehicle. The upper surface of the rolling brush 35 communicates with the entrance of the trash bin 2, and the engine 8 is connected to the tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com