Composite transmission environmental sanitation dumper

A compound transmission and cleaning vehicle technology, applied in the field of compound transmission sanitation cleaning vehicles, can solve the problems of high fuel consumption, high manufacturing cost of power batteries, low hydraulic transmission transmission efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

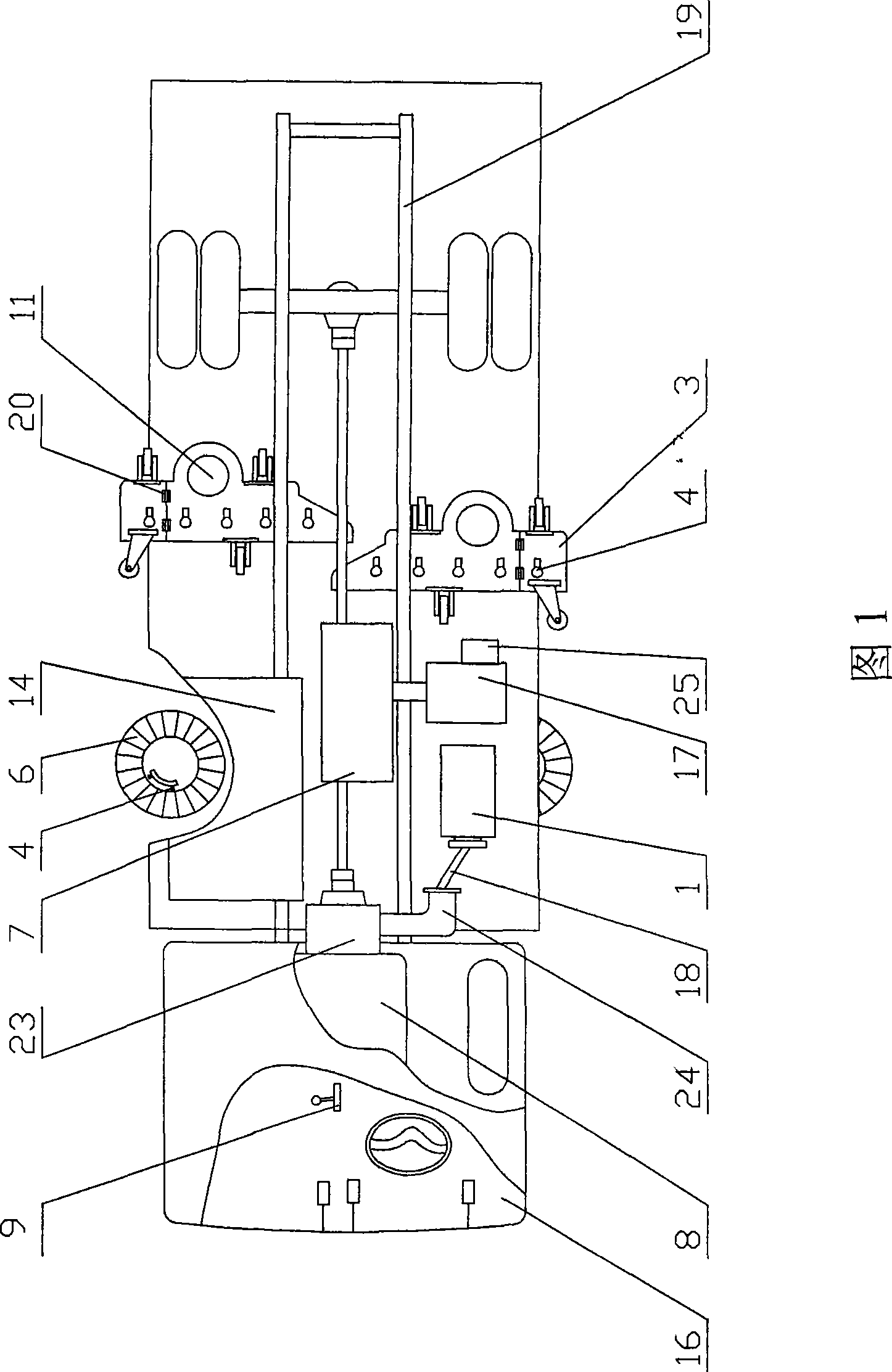

[0036] The first embodiment is a composite transmission dust suction sanitation cleaning vehicle, as shown in FIG. 1 . Fig. 1 is a schematic diagram of the basic structure of the dust-absorbing and sanitation cleaning vehicle of the present invention.

[0037] Said vehicle frame 19 is equipped with driver's cab 16, engine 8, dustbin 2, blower fan 7, sucker 3, suction cylinder 11, and said suction cup 3 is equipped with suction cylinder 11 Unicom dustbin 2, and the intake of said blower fan 7 The tuyere is connected to the dustbin 2, and the engine 8 is sequentially connected to the transmission transmission 23, the transmission shaft, and the rear axle shaft to drive the vehicle. Silicon rectifier generator 1, the silicon rectifier generator 1 is connected to battery 14 and power converter 25 at the same time, power converter 25 is connected to motor A17, motor A17 is connected to transmission fan 7, and in the driver's cab 16 li is equipped with off and on The transmission 2...

no. 2 example

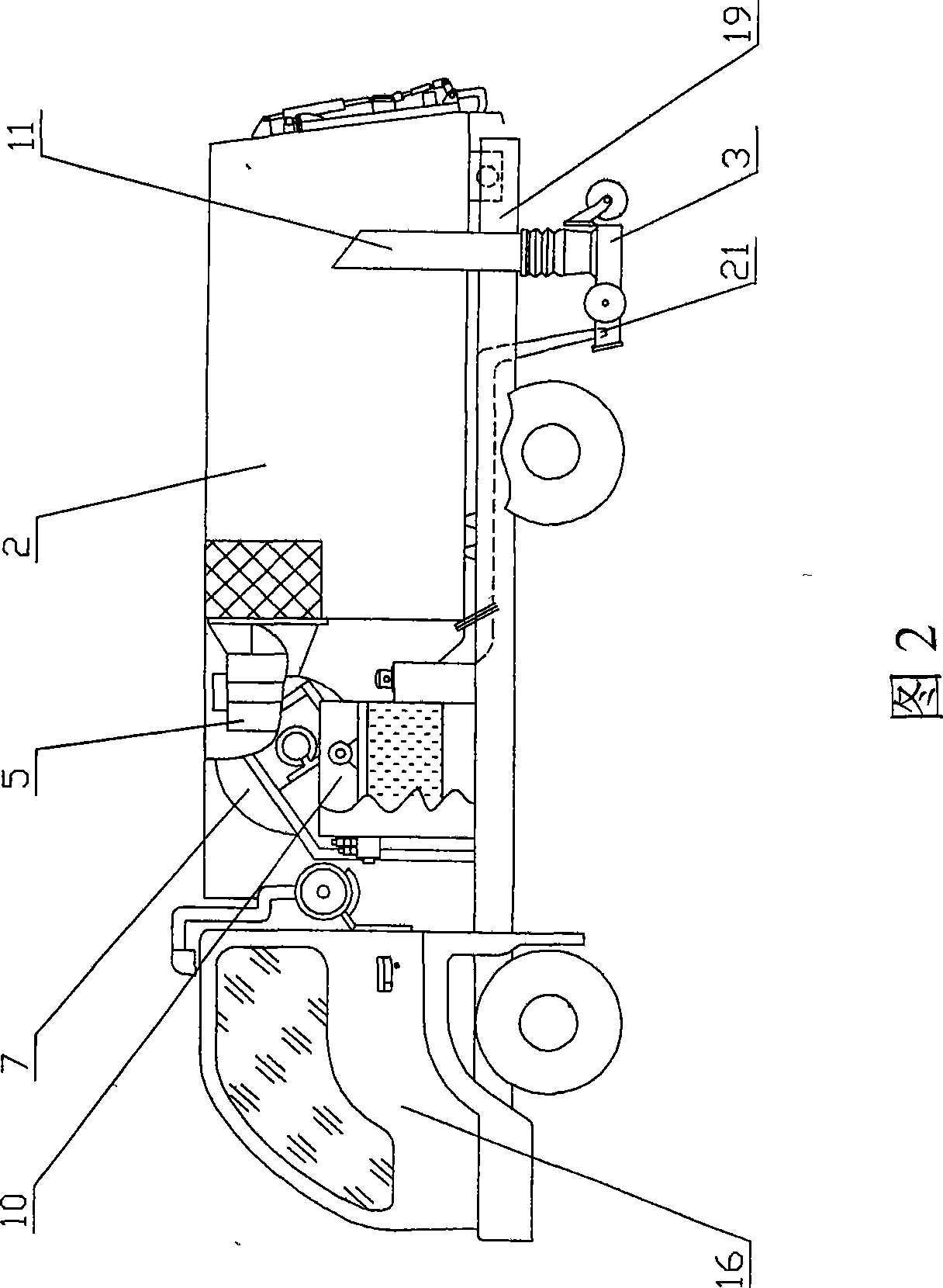

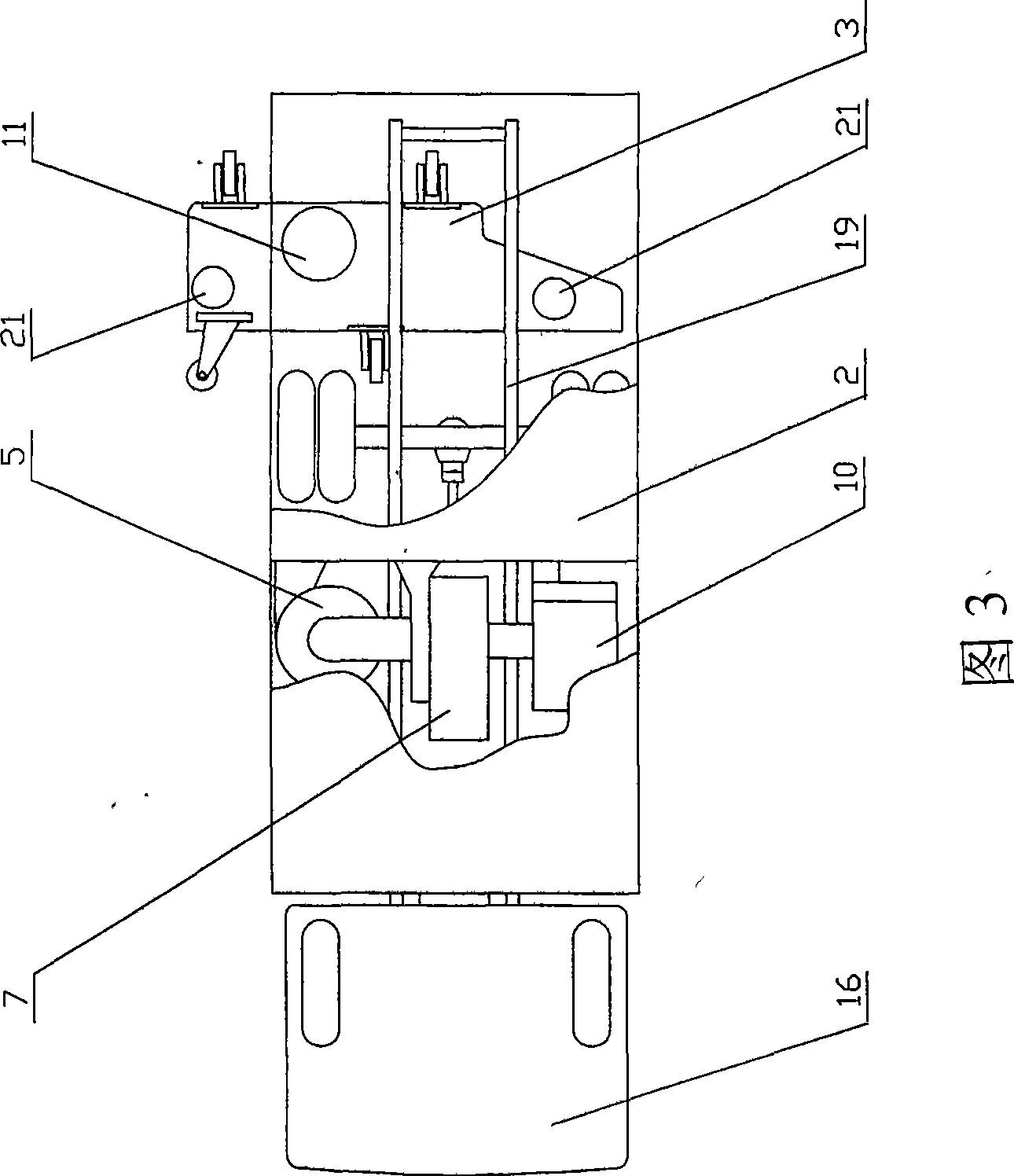

[0050] The second embodiment, the second embodiment is an expansion on the basis of the compound transmission structure of the first embodiment, it is a compound transmission sanitation cleaning vehicle that works in a dry dust filtration mode, as shown in Figure 2 and Figure 3 . Fig. 2 is a schematic diagram of the structure of the dust suction and sanitation cleaning vehicle of the second embodiment, and Fig. 3 is a schematic top view of Fig. 2 .

[0051] On the basis of the compound transmission structure of the first embodiment, a suction cup 3 is installed on the vehicle frame 19, and a suction cylinder 11 is installed on the suction cup 3 to communicate with the garbage bin 2; a cyclone separator 5 is installed on the vehicle frame 19, so that The air inlet of the cyclone separator 5 is connected to the dustbin 2, the air outlet of the air outlet is connected to the air inlet of the ventilator 7, the air inlet of the fan 7 is respectively connected to the air outlet of th...

no. 3 example

[0055]The third embodiment, the third embodiment is a compound drive sweeping and suction cleaning vehicle, which is an expansion on the basis of the transmission structure and dust suction operation structure of the first embodiment, as shown in Figure 4. Fig. 4 is a schematic structural diagram of a compound transmission sweeping, dust-absorbing and sanitation cleaning vehicle according to a third embodiment of the present invention.

[0056] On the basis of the compound transmission structure of the first embodiment, a suction cup 3 is installed on the vehicle frame 19, and a suction cylinder 11 is installed on the suction cup 3 to communicate with the dustbin 2, and the air inlet of the fan 7 is connected to the dustbin 2; The two sides of the vehicle frame 19 and the front of the suction cup 3 are respectively equipped with butterfly-shaped sweeping brushes 6, and the battery 14 is connected to the motor to drive the butterfly-shaped sweeping brushes 6 for cleaning operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com