Continuous cleaning equipment system for strip

A technology for cleaning equipment and strips, which is applied to lighting and heating equipment, cleaning methods and utensils, heating to dry solid materials, etc., can solve the problems of low cleaning cleanliness and low cleaning efficiency, and achieve the goal of saving production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

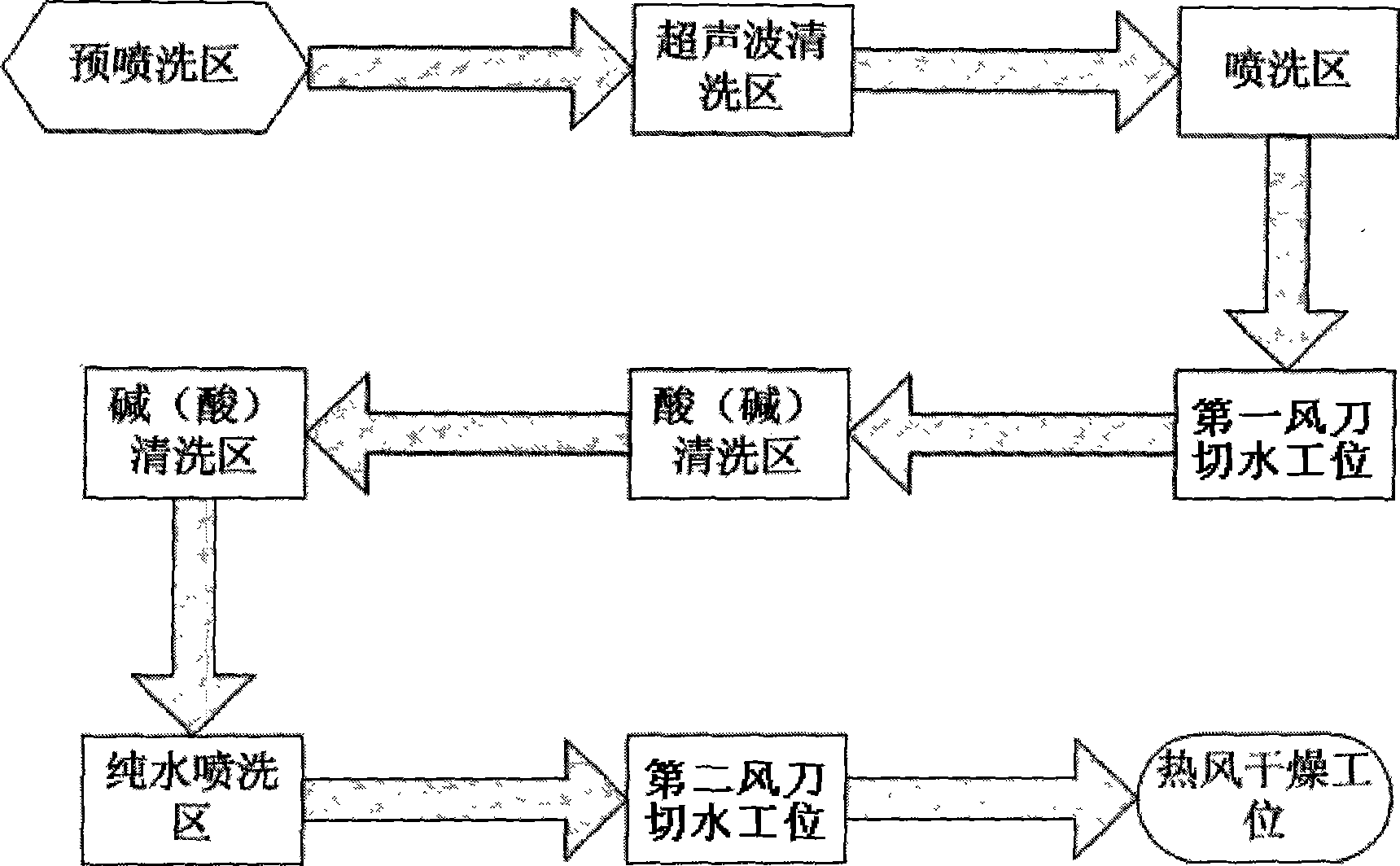

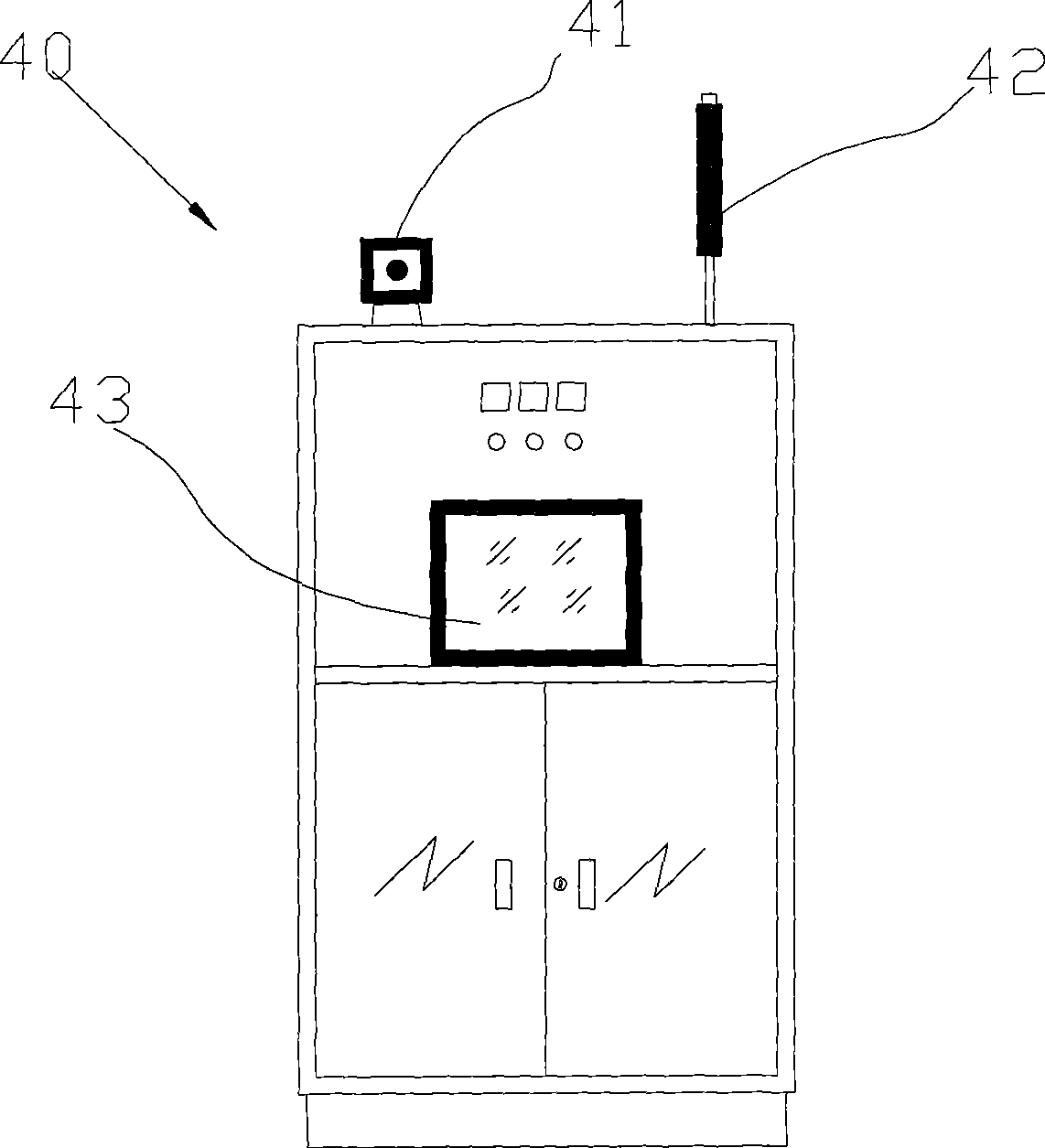

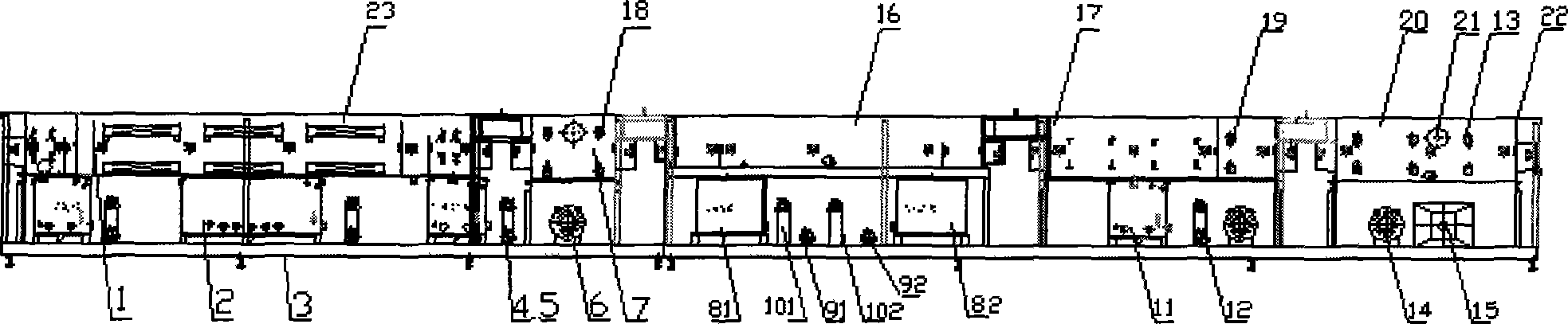

[0030] see Figure 1 to Figure 4 As shown, a strip continuous cleaning equipment system includes a pre-spray area station 24, an ultrasonic cleaning area station 25, a spray area station 26, a first Air knife water cutting station 27, acid or alkali cleaning station 28, pure water spray washing station 29, the second air knife water cutting station 30 and hot air drying station 31, the above stations are connected with the PLC controller connected, the PLC controller detects and controls the strip to be input from station 24 in the pre-spray area, and output after ultrasonic cleaning, spray washing, air drying, acid-base cleaning, pure water cleaning, and drying. figure 2 It is a PLC control cabinet, which mainly acts as the nervous system of the system operation, scheduling the cooperation and unified operation of each station. On the front panel of the control cabinet, there are instruments and a PLC controller with LCD touch screen 43. The control cabinet 40 is a double-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com