Method of electrolytically extracting and detecting fine inclusions in steel

An electrolytic extraction and inclusion technology, applied in the field of metal physics research, can solve the problems of inability to extract and separate fine non-metallic inclusions, accurate detection, etc., achieve good electron microscope observation effect, avoid loss, and facilitate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Organic electrolyte electrolysis

[0034] Prepare organic electrolyte, the formula of electrolyte is as follows: (wt%)

[0035] Tetramethylammonium chloride 1%, acetylacetone 15%, the balance is anhydrous methanol.

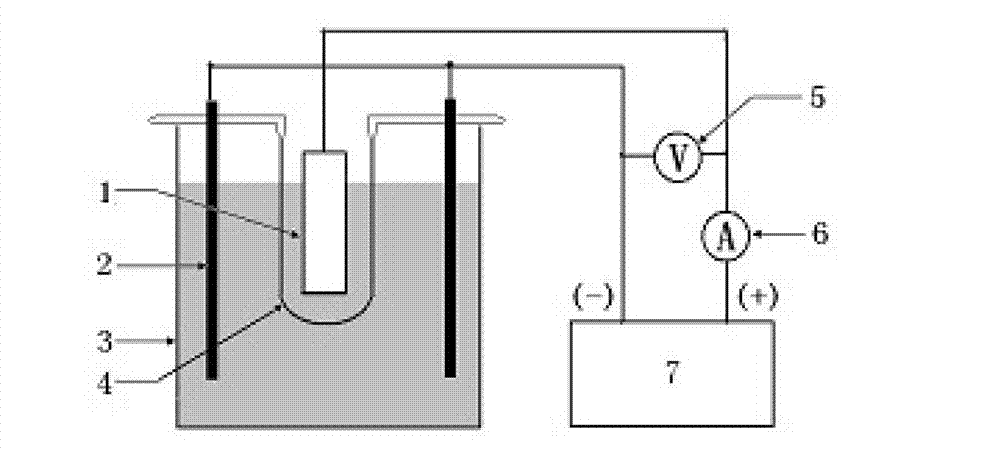

[0036] Put the above electrolytic solution into the electrolytic cell 3, use the pipeline steel X70 steel sample containing inclusions as the anode, and the stainless steel cylinder 2 as the negative electrode, and put the electrolytic cell into the refrigerator, press figure 1 Connect the experimental device as shown to perform constant current electrolysis on the steel sample, control the electrolysis temperature in the refrigerator to -15°C, and adjust the current density to 0.05A / cm 2 , electrolysis for 4 hours.

[0037] 2. Magnetic separation

[0038] Clean the electrolyte containing inclusions after electrolysis with absolute ethanol, and perform magnetic separation with a magnet to suck out the iron particles and cementite mixed in inclusions t...

Embodiment 2

[0048] 1. Organic electrolyte electrolysis

[0049] Prepare organic electrolyte, the formula of electrolyte is as follows: (wt%)

[0050] Tetramethylammonium chloride 1%, acetylacetone 10%, the balance is anhydrous methanol.

[0051] Put the above electrolytic solution into the electrolytic cell 3, use the H40 steel sample containing inclusions as the anode, and the stainless steel cylinder 2 as the negative electrode, and put the electrolytic cell into the refrigerator, press figure 1 Connect the experimental device as shown to perform constant current electrolysis on the steel sample, control the electrolysis temperature in the refrigerator to -15°C, and adjust the current density to 0.03A / cm 2 , electrolysis for 4 hours.

[0052] 2. Magnetic separation

[0053] Clean the electrolyte containing inclusions after electrolysis with absolute ethanol, and perform magnetic separation with a magnet to suck out the iron particles and cementite mixed in inclusions that fall off du...

Embodiment 3

[0063] 1. Organic electrolyte electrolysis

[0064] Prepare organic electrolyte, the formula of electrolyte is as follows: (wt%)

[0065] Tetramethylammonium chloride 1%, acetylacetone 10%, the balance is anhydrous methanol.

[0066] Put the above electrolytic solution into the electrolytic cell 3, use the S23 silicon steel sample containing inclusions as the anode, and the stainless steel cylinder 2 as the negative electrode, and put the electrolytic cell into the refrigerator, press figure 1 Connect the experimental device as shown to perform constant current electrolysis on the steel sample, control the electrolysis temperature in the refrigerator to -15°C, and adjust the current density to 0.05A / cm 2 , electrolysis for 3 hours.

[0067] 2. Magnetic separation

[0068] Clean the electrolyte containing inclusions after electrolysis with absolute ethanol, and perform magnetic separation with a magnet to suck out the iron particles and cementite mixed in inclusions that fal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com