Method for cleaning polyphenylene sulfide melt spinning spinneret

A technology of polyphenylene sulfide and melt spinning, which is applied in the direction of spinneret assemblies, textiles and papermaking, and can solve problems such as spinneret hole peeling effect, chemical corrosion, and spinneret hole deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The present invention will be further described below in conjunction with accompanying drawing:

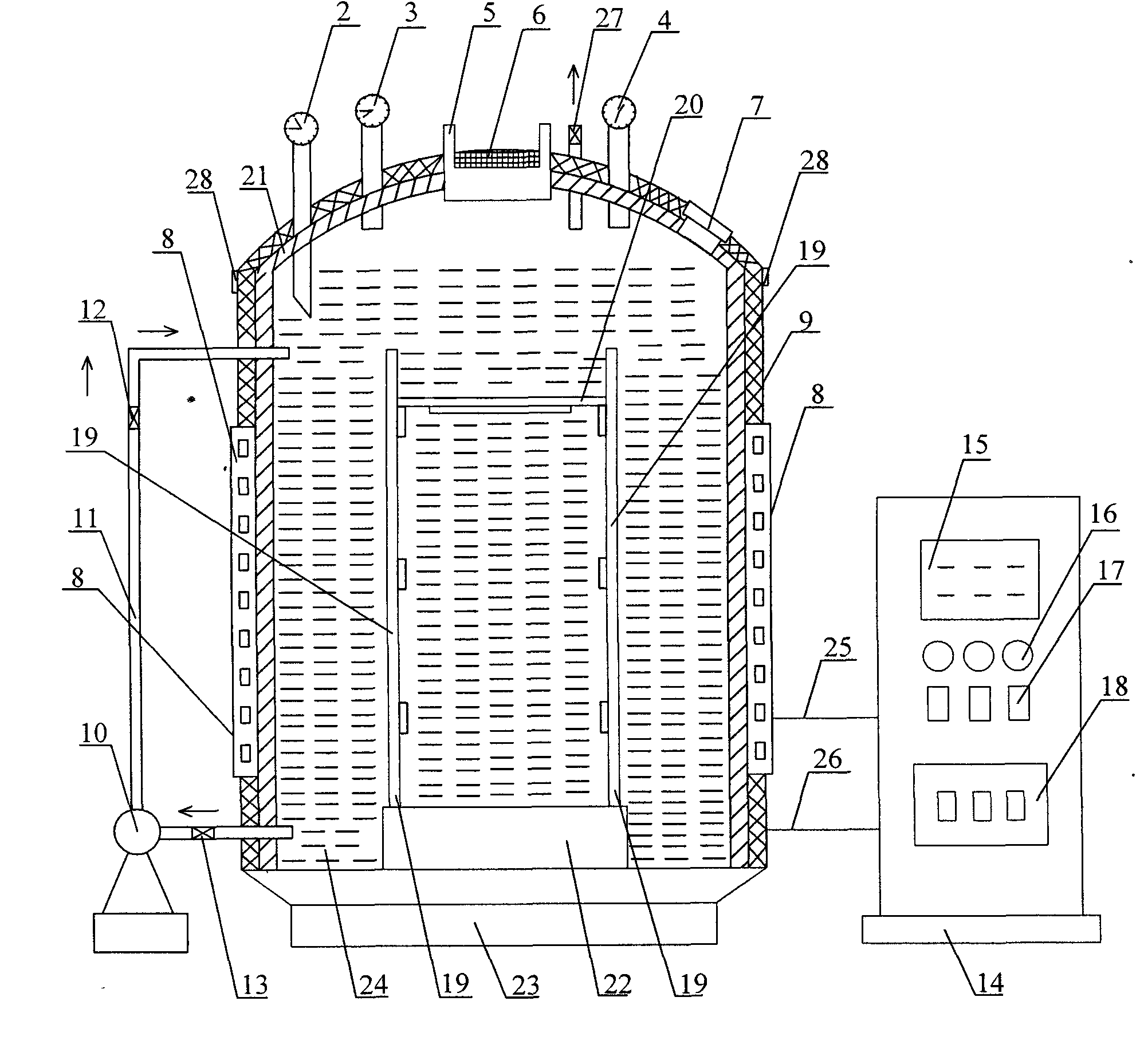

[0077] figure 1 Shown is the cleaning state diagram of the cleaning tank, the position and connection relationship of each part must be correct, and the installation should be firm.

[0078] The biphenyl-diphenyl ether cleaning solution in the cleaning tank should be sufficient, and 90% of the liquid should be kept in the tank cavity to ensure that the cleaning solution submerges the spinneret during the flow process.

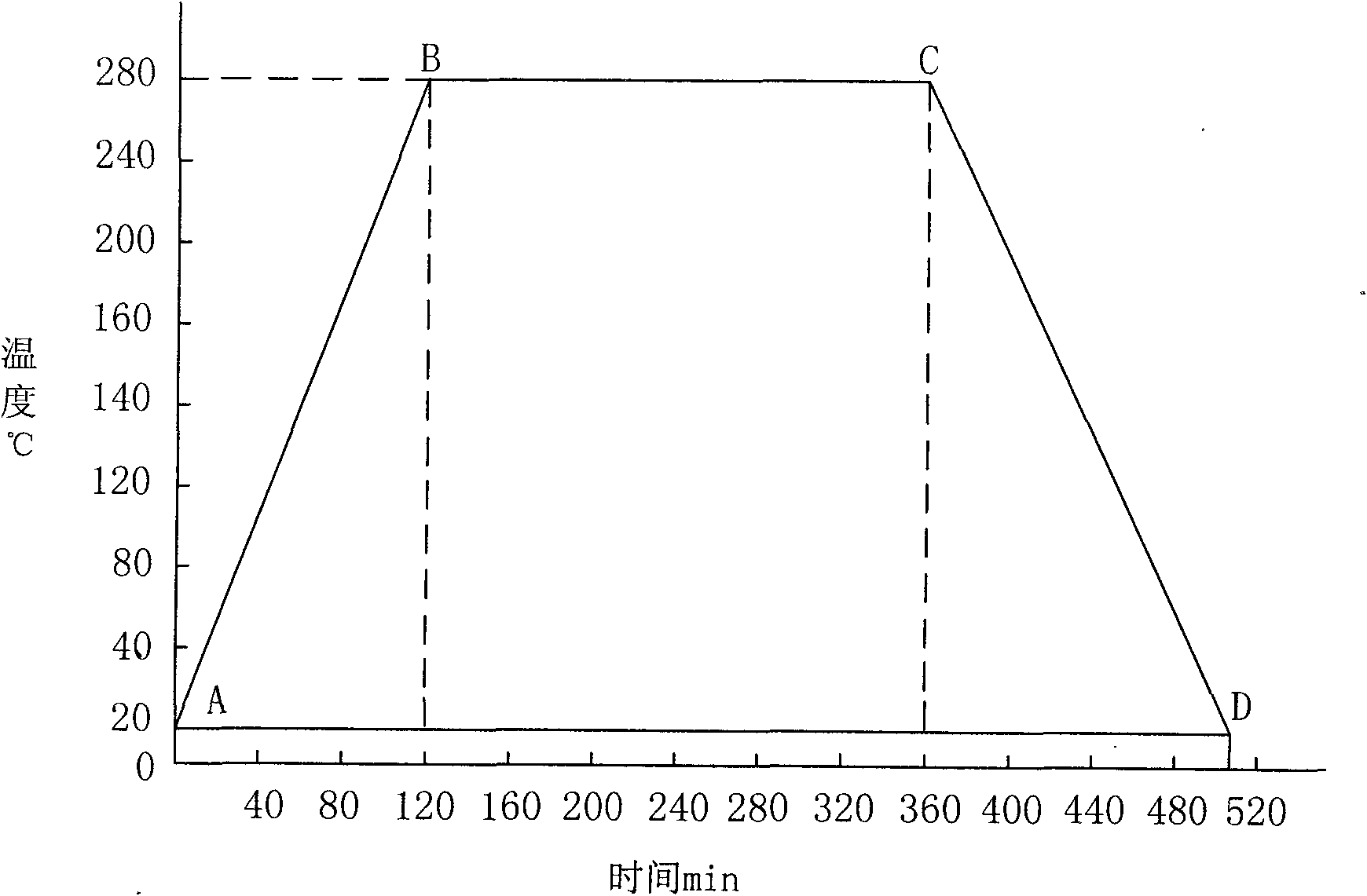

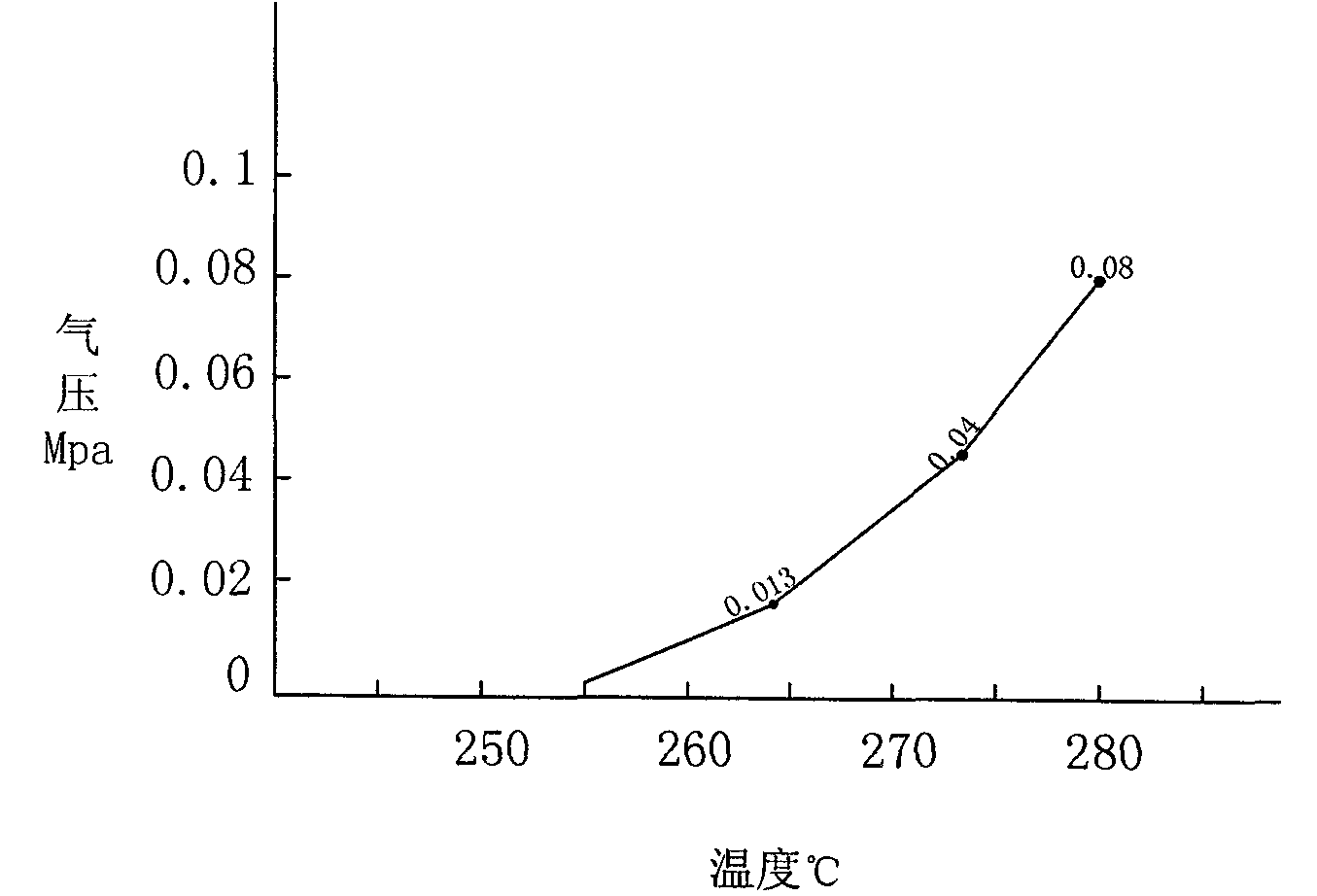

[0079] The temperature in the cleaning kettle is kept constant at 280°C±1°C. This temperature can control the pressure inside the kettle to be 0.08Mpa and keep constant. Proportional.

[0080] The temperature in the cleaning tank is heated by microwave, which has good heating effect and energy saving. It is controlled by the microwave controller on the electric control cabinet and displays its power.

[0081] The liquid inlet pump, liquid inlet valve, liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com