Filling composite welding flux vibrating liquid phase welding method for non-continuous strengthening aluminium base composite material

A technology for strengthening aluminum matrix and composite materials, which is applied in welding/cutting medium/material, welding medium, welding equipment, etc., and can solve the problems of high surface roughness to be welded, large difference in melting point of reinforcing phase, influence of joint strength, etc. , to improve the microscopic bonding interface, avoid enhanced phase segregation, and improve the performance of the joint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The following examples describe the present invention in more detail:

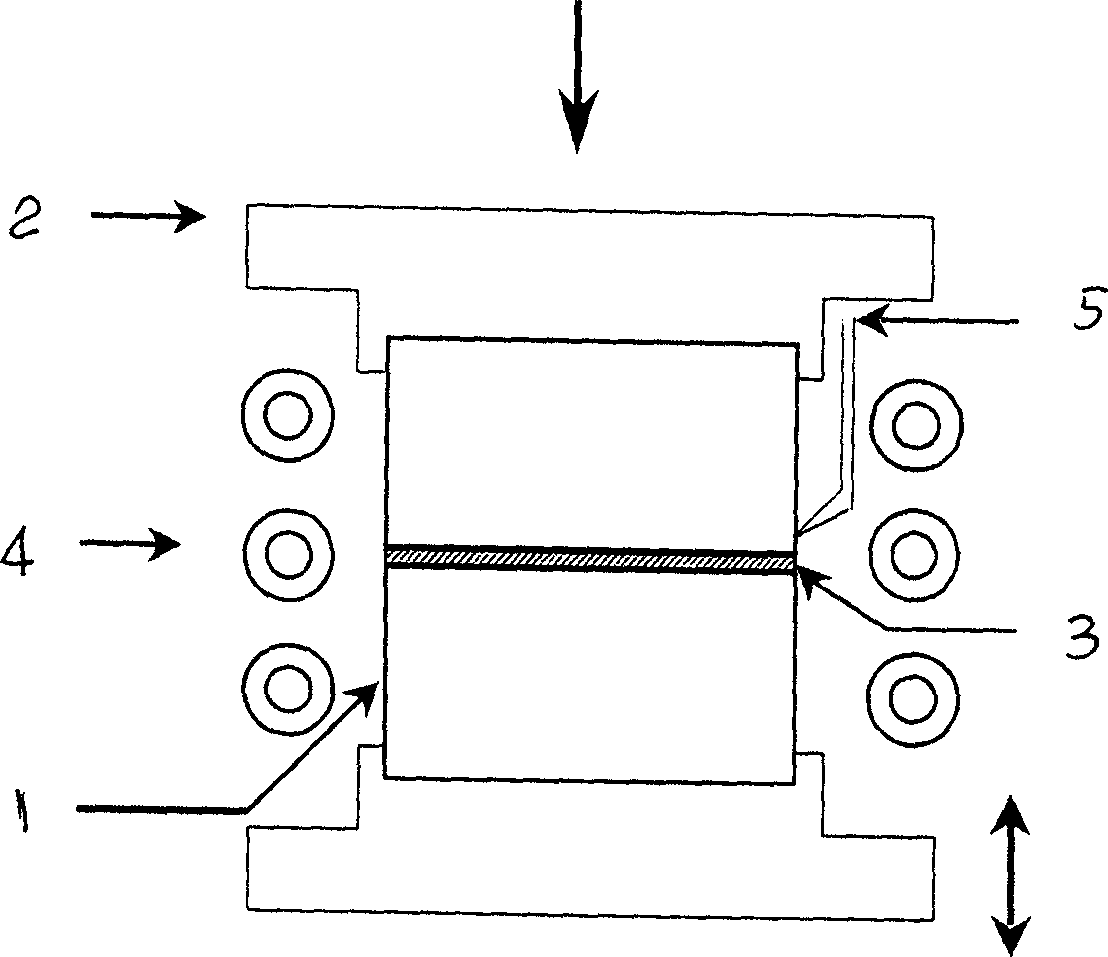

[0053] First use 400# sandpaper to polish the discontinuously reinforced aluminum matrix composite material, and perform ultrasonic cleaning in acetone. After the cleaned discontinuously reinforced aluminum matrix composite material 1 is dried, it is clamped in the form of a butt joint in the fixture 2 place the composite solder 3 between the surfaces of two discontinuous reinforced aluminum matrix composite materials to be welded, and heat the composite solder through the heater 4 to fully melt the composite solder. The heating temperature range is 380-620°C, and is controlled by the thermocouple 1. Keep the welding temperature, start the vibration device and apply pre-pressure. The vibration adopts one of the following two methods: use low-frequency vibration with a frequency of 50-4000 Hz and an amplitude of 0-1.5 mm, and the vibration time is 0.1-5 minutes. The pressure range is 0.25 ~ 10Mpa; or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com