Brush roll cleaning process in stainless steel hot-rolled sheet acid cleaning process and brush roll therefor

A technology of hot-rolled plate and stainless steel, applied in the brush roller cleaning method and brush stick field, can solve the problems of short service life, achieve good wear resistance, improve cleaning quality, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

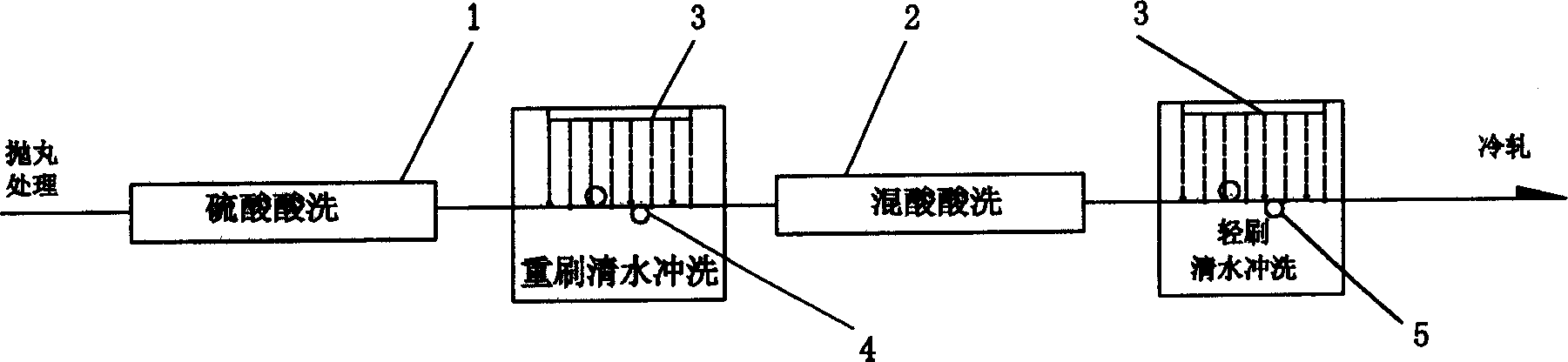

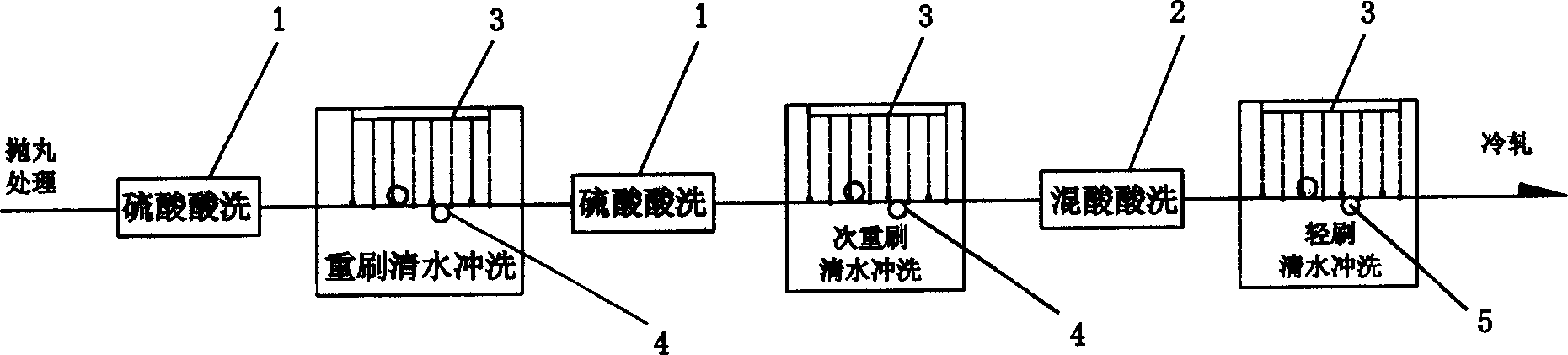

[0020] figure 1 Shown, a kind of brush roll cleaning method in the pickling process of stainless steel hot-rolled plate, comprises:

[0021] Shot blasting; removal of scale, pretreatment.

[0022] Sulfuric acid pickling; untreated shot blasting to remove iron oxide scales.

[0023] The first brush roller cleaning; it is called heavy brush cleaning; it uses a nylon wire brush roller with a diameter of 1.2-1.5mm and a silicon carbide abrasive of 80-100 mesh.

[0024] Hydrofluoric acid + nitric acid mixed acid pickling; passivation treatment.

[0025] The second brush roller cleaning is the brush roller cleaning at the outlet of the stainless hot plate, also known as light brush cleaning. It uses a nylon brush roller with a diameter of about 0.5mm and contains micronized silicon carbide abrasives.

[0026] The cleaned sheet is sent to the cold rolling mill for rolling, and then the cold-rolled sheet is produced by the cold sheet pickling line.

[0027] The sulfuric acid tank ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com