Automatic glue brushing device for brake pad manufacture

A brake pad and glue brushing technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of difficult cleaning, low practicability, and easy contamination of workers' clothes or skin by the colloid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

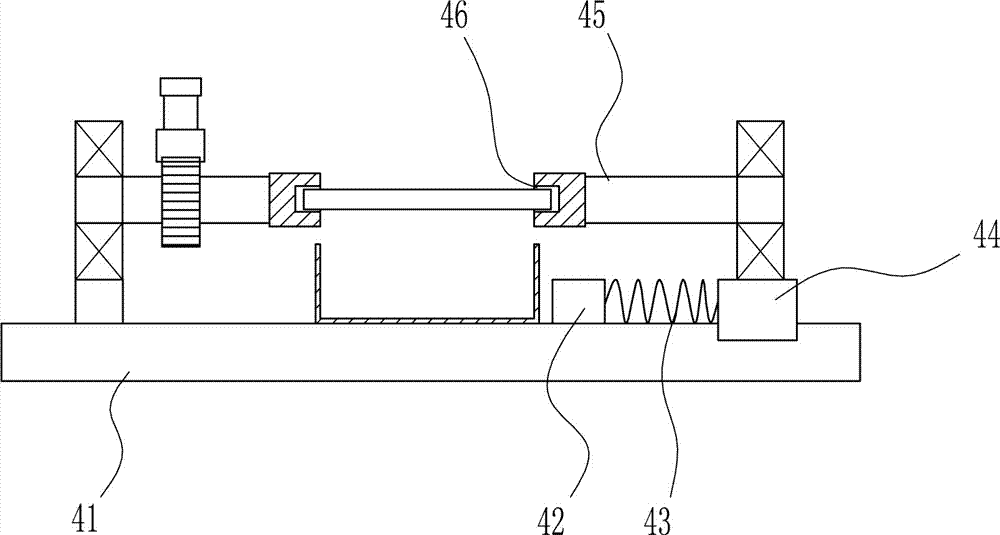

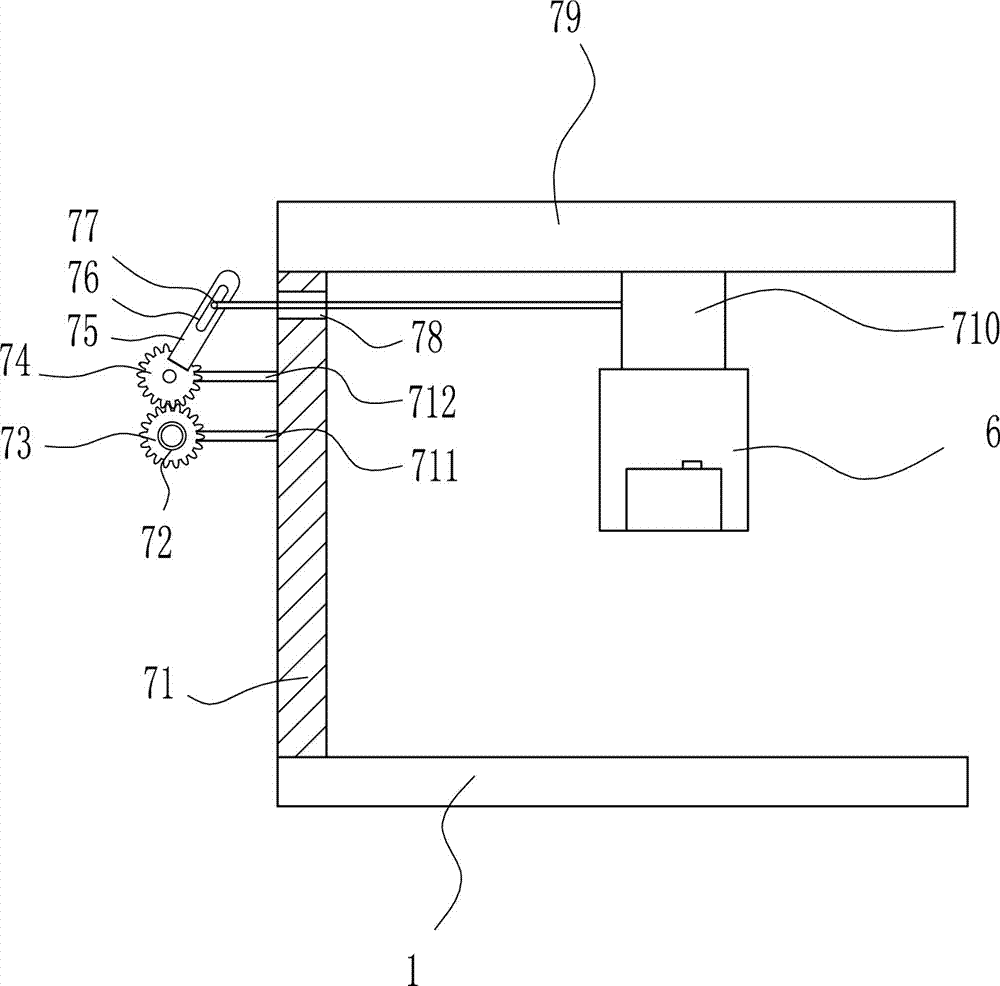

[0035] An automatic glue brushing device for brake pad production, such as Figure 1-7 As shown, it includes a bottom plate 1, an anti-glue frame 2, a rotating mechanism 3, a clamping mechanism 4, a lifting mechanism 5, a glue discharge mechanism 6, a front and rear moving mechanism 7, and a brush 8. The top surface of the bottom plate 1 is arranged sequentially from back to front. There are forward and backward moving mechanism 7, rotating mechanism 3 and clamping mechanism 4. Lifting mechanism 5 is arranged in front of the bottom of forward and backward moving mechanism 7. Glue discharging mechanism 6 is arranged on the right side and bottom of lifting mechanism 5. Brush is arranged at the bottom of glue discharging mechanism 6. 8. The glue discharging mechanism 6 is located directly above the clamping mechanism 4.

Embodiment 2

[0037] An automatic glue brushing device for brake pad production, such as Figure 1-7 As shown, it includes a bottom plate 1, an anti-glue frame 2, a rotating mechanism 3, a clamping mechanism 4, a lifting mechanism 5, a glue discharge mechanism 6, a front and rear moving mechanism 7, and a brush 8. The top surface of the bottom plate 1 is arranged sequentially from back to front. There are forward and backward moving mechanism 7, rotating mechanism 3 and clamping mechanism 4. Lifting mechanism 5 is arranged in front of the bottom of forward and backward moving mechanism 7. Glue discharging mechanism 6 is arranged on the right side and bottom of lifting mechanism 5. Brush is arranged at the bottom of glue discharging mechanism 6. 8. The glue discharging mechanism 6 is located directly above the clamping mechanism 4.

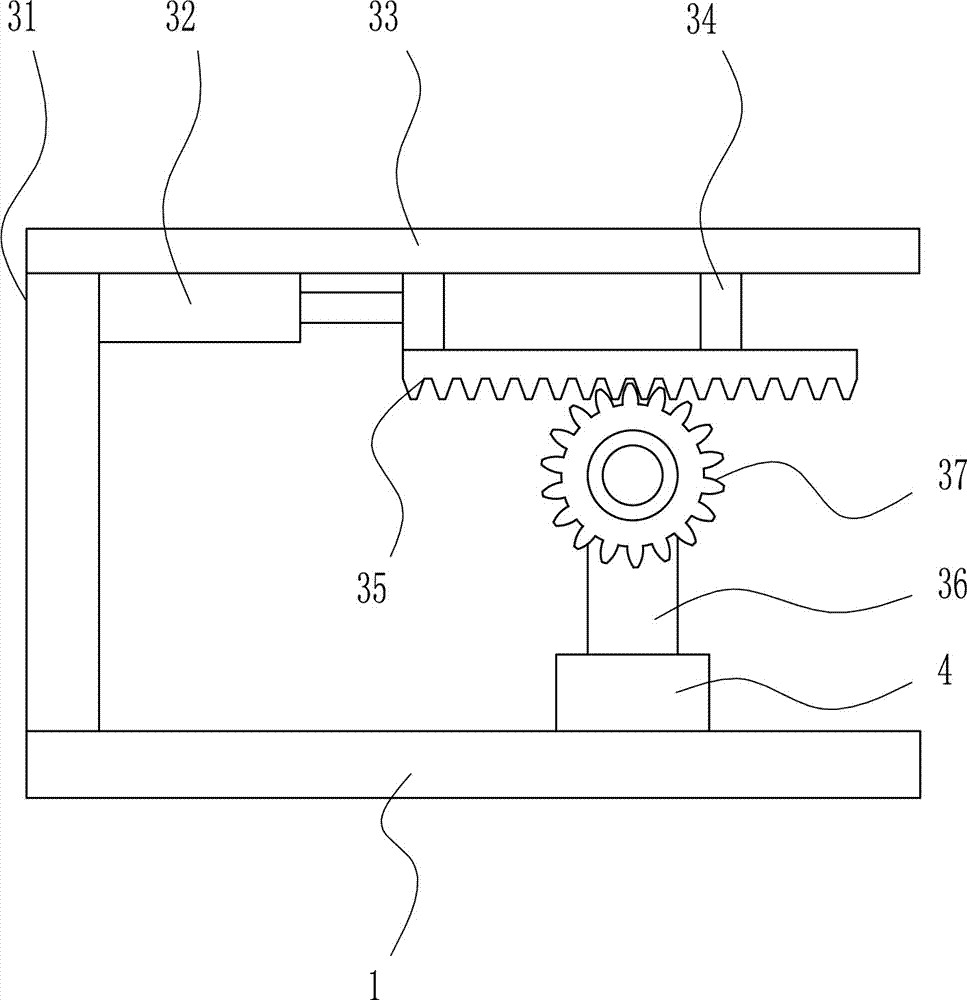

[0038] Turning mechanism 3 comprises pole 31, electric push rod 32, first slide rail 33, first slide block 34, first rack 35, first bearing seat 36, first gear ...

Embodiment 3

[0040] An automatic glue brushing device for brake pad production, such as Figure 1-7 As shown, it includes a bottom plate 1, an anti-glue frame 2, a rotating mechanism 3, a clamping mechanism 4, a lifting mechanism 5, a glue discharge mechanism 6, a front and rear moving mechanism 7, and a brush 8. The top surface of the bottom plate 1 is arranged sequentially from back to front. There are forward and backward moving mechanism 7, rotating mechanism 3 and clamping mechanism 4. Lifting mechanism 5 is arranged in front of the bottom of forward and backward moving mechanism 7. Glue discharging mechanism 6 is arranged on the right side and bottom of lifting mechanism 5. Brush is arranged at the bottom of glue discharging mechanism 6. 8. The glue discharging mechanism 6 is located directly above the clamping mechanism 4.

[0041] Turning mechanism 3 comprises pole 31, electric push rod 32, first slide rail 33, first slide block 34, first rack 35, first bearing seat 36, first gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com