Equipment and method for intelligently automatically cleaning vehicle

An automatic car washing and equipment technology, applied in the direction of vehicle exterior cleaning devices, etc., can solve the problems of many special parts, prolonged car washing time, increased manufacturing and maintenance costs, etc., so as to reduce the probability of mechanical failure, reduce power consumption and Water consumption and the effect of saving post-maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

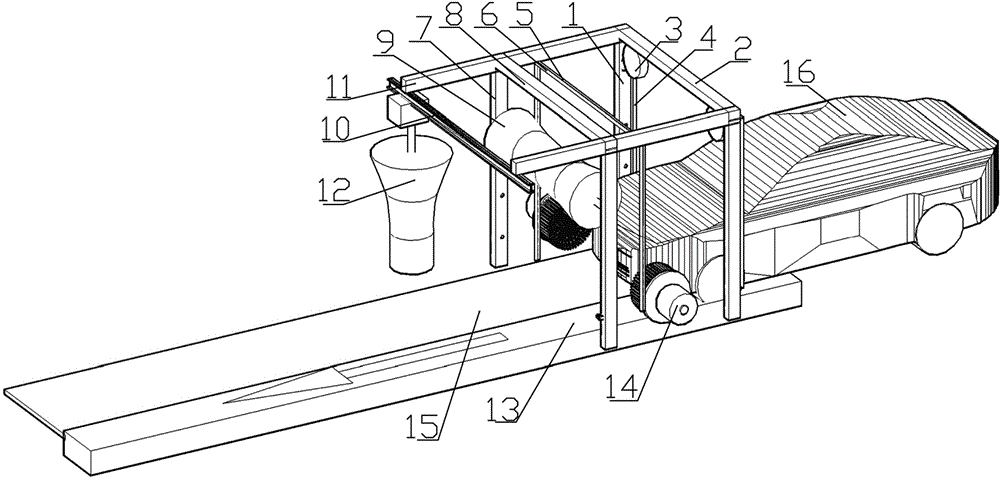

[0094] Such as Figure 1-13 As shown, a kind of intelligent automatic car washing equipment, it comprises traction guide rail 13, and described traction guide rail 13 is arranged on the side of ground grid 15, and the right end of described ground grid 15 is vertically installed with a No. 1 column 1, No. 1 column The top of No. 1 is fixedly connected to No. 1 beam 2, No. 2 column 7 is installed behind No. 1 column 1, and the top of No. 2 column 7 is fixedly connected to No. 2 beam 8. A longitudinal Beam 11, No. 3 crossbeam 10 is installed at the end of said longitudinal beam 11. The existing gantry-type car washing equipment needs to move the gantry during the car washing process, and the existing tunnel-type car washing equipment needs to solve the problem of the layout of many brush rollers, which leads to a relatively large space for car washing. In order to solve this problem, a pair of The reciprocating movement of the car and the optimization of the structural layout c...

Embodiment 2

[0114] The concrete work process of device of the present invention is:

[0115] The vehicle parks after entering the entrance of the car washing machine, puts it in neutral, and does not pull the handbrake. Start the car washing machine by remote control, and the vehicle will slowly drive into the car washing machine under the traction of the traction guide rail. When the front of the car reaches the position of the No. 1 column, the high-pressure water pump will start and open the solenoid valve. And the No. 1 water nozzle on the ground sprays high-pressure water to wash the body and chassis under high pressure, and the car slowly drives in while washing; when the front of the car reaches the position of the water wax nozzle, spray the body with water wax foam;

[0116] When the front wheel reaches the position of the wheel brush, the guide rail traction, water spraying, and water wax spraying are suspended, the wheel brush device is activated, and the wheel hub and tires ar...

Embodiment 3

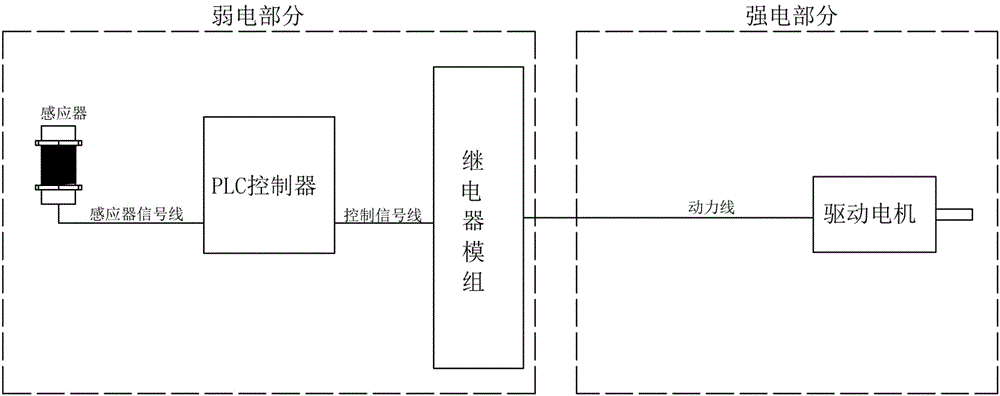

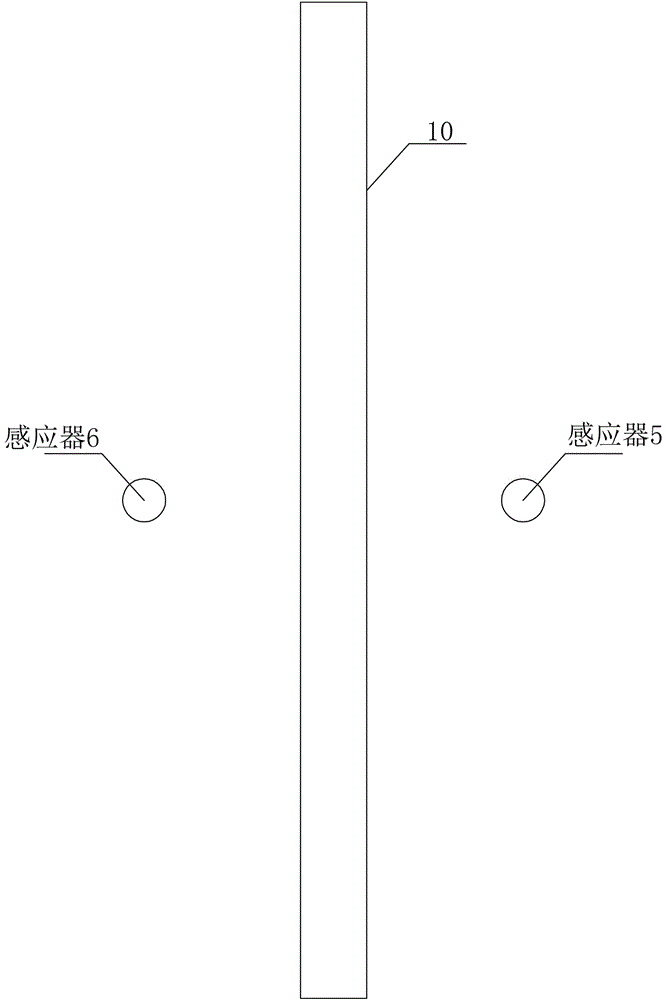

[0123] see Figure 13 , through the car wash flow chart to further explain the automated car wash process in detail, and at the same time explain its automation process and working principle, which is attached Figure 11 The sensor 1, sensor 2, sensor 3, sensor 4, sensor 5, sensor 6 and sensor 7 described in the embodiment 2 are the same as the first sensor, the second sensor, the third sensor Sensor, No. 4 sensor, No. 5 sensor, No. 6 sensor and No. 7 sensor correspond to each other. The detailed car washing process is:

[0124] 1. After the vehicle enters the entrance of the car washing machine, it stops in place, puts it in neutral, and does not pull the handbrake. Start the car washing machine by remote control, and the vehicle will slowly drive into the car washing machine under the traction of the traction guide rail. When the front of the car reaches the sensor 1, that is, the position of the No. 1 column A, the high-pressure water pump will start. 1, the No. 1 beam b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com