Star-shaped adamantane derivative molecular glasses, and preparation method and application thereof

A technology of molecular glass and adamantane, which is applied in the field of materials, can solve problems such as not being suitable for the requirements of scribe lines, and achieve the effect of simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

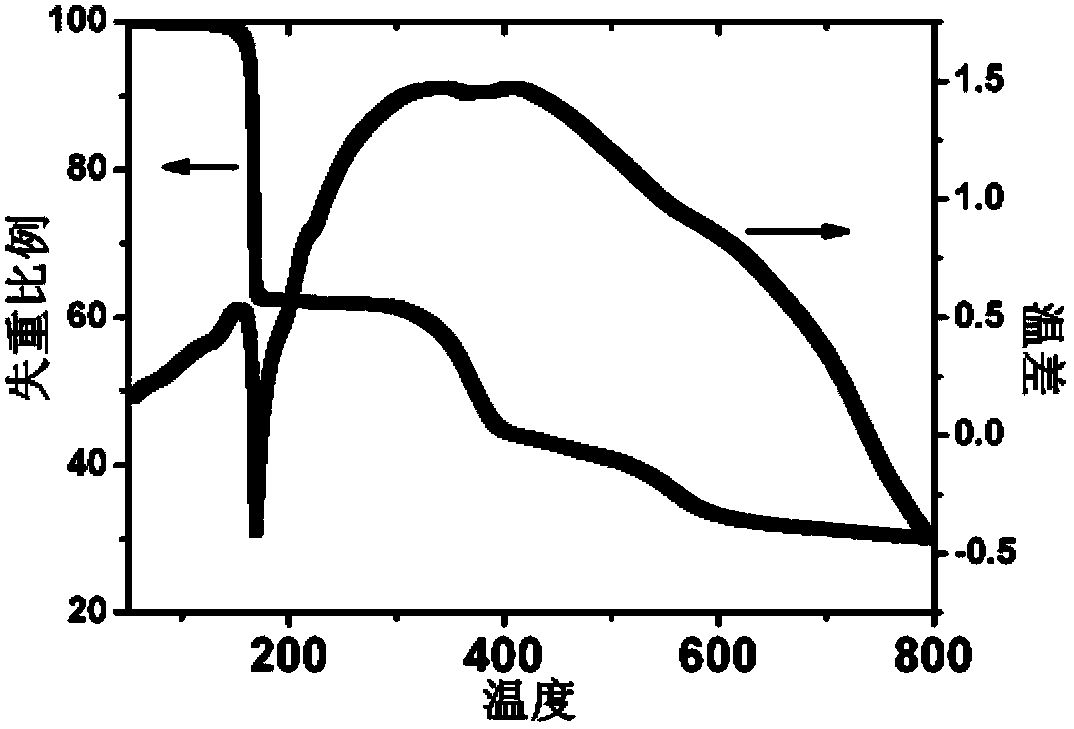

example 1

[0059] A preparation method of star adamantane derivative molecular glass, comprising the following steps:

[0060] 1) Preparation of 1,3,5,7-tetrakis-(7,8-dimethoxybiphenyl)adamantane, the synthetic route is as follows:

[0061]

[0062] Under the protection of high-purity nitrogen, 1,3,5,7-tetra-p-iodophenyladamantane (472.1mg, 0.5mmol, 1.0eq), Pd(PPh 3 ) 4 (57.8mg, 0.05mmol, 0.1eq) and redistilled toluene 10ml, after stirring and dissolving, add 3,4-dimethoxyphenyl pinacol borane (660mg2.50mmol, 5.0 eq) ethanol solution 3ml and 2M Na 2 CO 3 1ml of aqueous solution, the reaction solution was heated at 50-70°C and refluxed for 12h, cooled to room temperature, and 0.5ml of H 2 o 2 Excess borate was quenched, stirred for 1 h, and extracted with dichloromethane / water. The organic layers were combined, dried over anhydrous sodium sulfate, concentrated under reduced pressure to remove the solvent, and recrystallized in toluene to obtain 376 mg of a white solid with a yield...

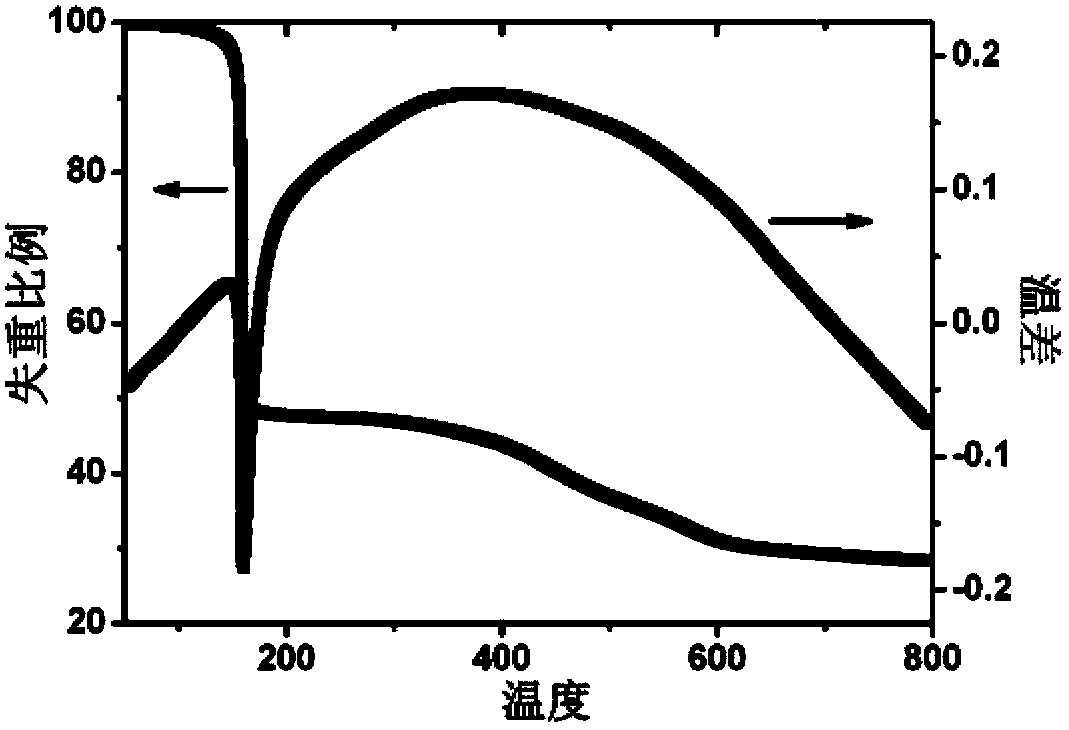

example 2

[0073] A preparation method of star adamantane derivative molecular glass, comprising the following steps:

[0074] 1) Preparation of 1,3,5,7-tetrakis-(7,8,9-trimethoxybiphenyl)adamantane, the synthetic route is as follows:

[0075]

[0076] Under nitrogen protection, 1,3,5,7-tetraiodophenyladamantane (472.1mg, 0.5mmol, 1.0eq), Pd(PPh 3 ) 4 (57.8mg, 0.05mmol, 0.1eq) and redistilled toluene 10ml, stirred and dissolved, then added 3,4,5-trimethoxyphenylboronic acid (530mg, 2.50mmol, 5.0eq) in ethanol solution 3ml with a syringe and 2M Na 2 CO 3 solution 1ml, the reaction solution was heated at 50-70°C and refluxed for 12h, cooled to room temperature, and 0.5ml H 2 o 2 Excess boronate was quenched and stirred for 1 h. Extract with dichloromethane / water, combine the organic layers, dry over anhydrous sodium sulfate, concentrate under reduced pressure to remove the solvent, recrystallize in toluene to obtain 398 mg of white solid, yield 72%. 1 H NMR (400MHz, CDCl 3 )δ(pp...

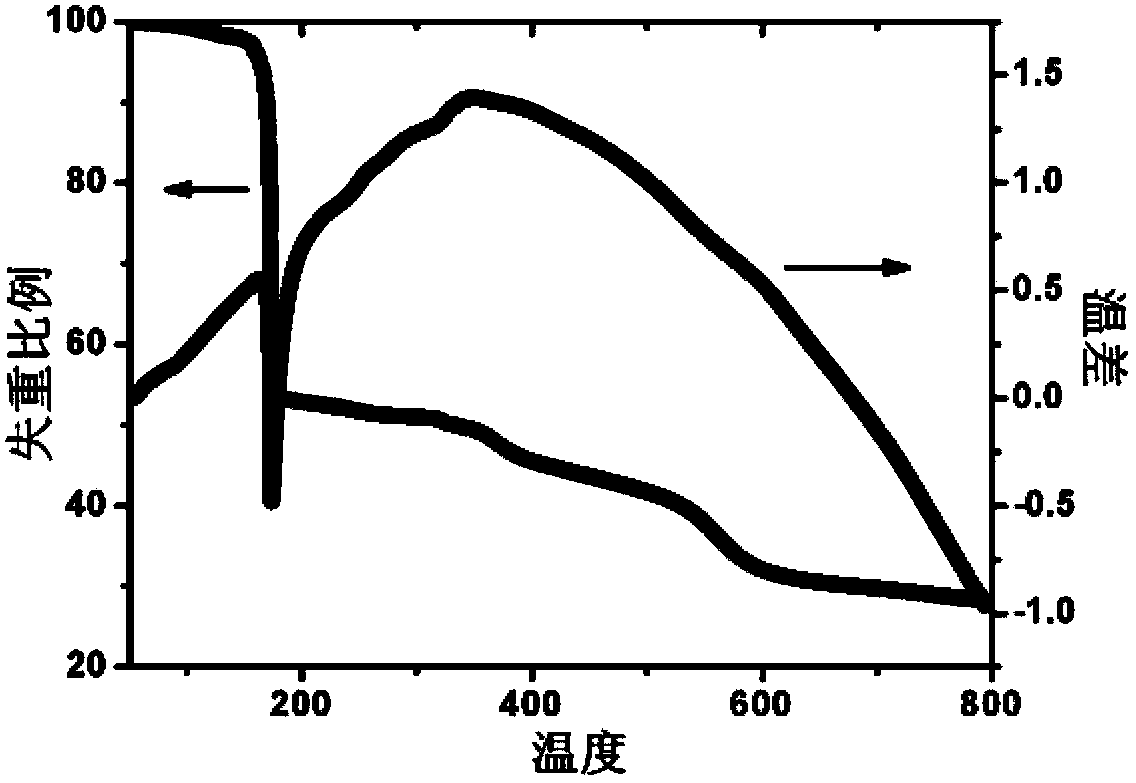

example 3

[0086] Steps 1) and 2) are the same as in Example 1.

[0087] 3) Preparation of 1,3,5,7-tetrakis-(7-hydroxy-8-acetate adamantyl biphenyl)adamantane, the synthetic route is as follows:

[0088]

[0089] AD in the reaction formula represents Substituents.

[0090] Add 1,3,5,7-tetrakis-(7,8-dihydroxybiphenyl)adamantane (875mg, 1.0mmol, 1.0eq), tetrabutylammonium bromide (400mg, 1.2mmol ,1.2eq), K 2 CO 3 (2.8g, 20mmol) and N-methylpyrrolidone (NMP, 50ml), stirred at room temperature for 2 hours, slowly added NMP (10ml ) solution, heated to 60°C for 48h. After the reaction is complete, cool to room temperature, the reaction solution is extracted with ethyl acetate / water, the organic phase is washed once with 3wt% oxalic acid solution and water respectively, the organic layers are combined, dried over anhydrous magnesium sulfate, the solvent is removed under reduced pressure, and the residue is washed with Ethyl acetate / n-hexane mixed solvent was recrystallized to obtain 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com