Nanometer composite hydrophobic hard transparent film and preparation method thereof

A nano-composite, transparent film technology, applied in chemical instruments and methods, other chemical processes, etc., can solve problems affecting industrial production, complex processes, etc., and achieve the effect of improving service life, high purity, and preventing snow accumulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

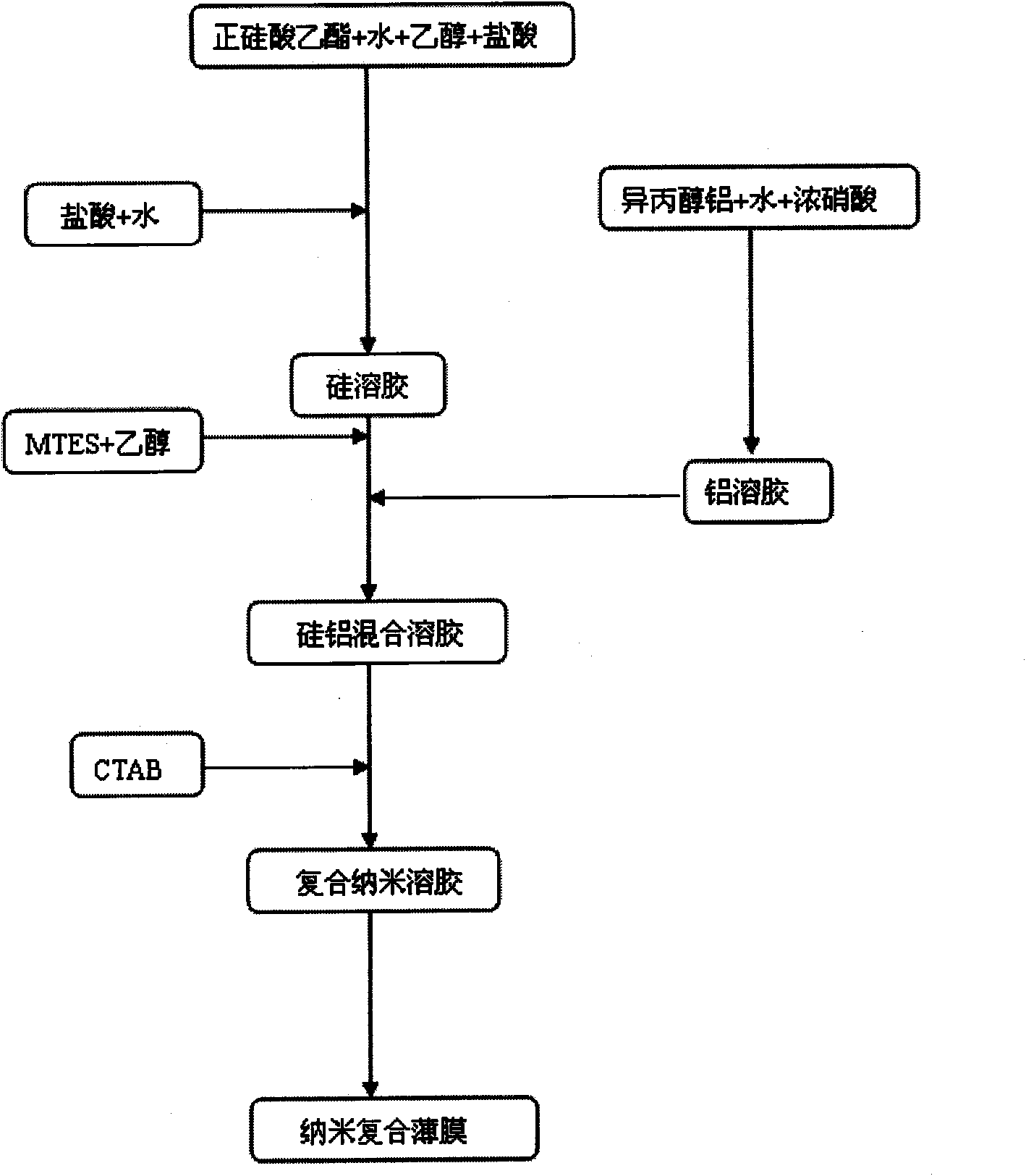

Method used

Image

Examples

Embodiment 1

[0040] (1), preparation of silica sol

[0041] SiO 2 Content is 28.4% orthoethyl silicate (TEOS), absolute ethanol, water and pH are the hydrochloric acid of 2.56 molar ratio: 1: 3.8: 1: 5 * 10 -5 Mix, hydrolyze, stir at 60°C for 90 minutes, let the sol cool to room temperature to obtain a partially hydrolyzed and polycondensed silica sol, and let it stand for about 12 hours;

[0042]Add HCl and water with a volume ratio of 0.035:1 to the partially hydrolyzed and polycondensed silica sol obtained by naturally cooling to room temperature, so that the concentration of the partially hydrolyzed and polycondensed silica sol reaches 0.01M, and stir at room temperature for 15 minutes. Aging sol at 50°C for about 0 to 16 hours, then drop in ethanol with a concentration of 99.7% for dilution, let it stand for about 5 hours, then add methyltriethoxysilane, and finally react to form silica sol;

[0043] The molar ratio of the final reagent is tetraethyl orthosilicate (TEOS): ethanol: w...

Embodiment 2

[0052] (1), preparation of silica sol

[0053] SiO 2 Content is 28.4% orthoethyl silicate (TEOS), absolute ethanol, water and pH are 2.56 hydrochloric acid molar ratio: 1: 3.8: 1: 5 × 10 -5 Mix, hydrolyze, stir at 60°C for 90 minutes, let the sol cool to room temperature to obtain a partially hydrolyzed and polycondensed silica sol, and let it stand for about 12 hours;

[0054] Add HCl and water with a volume ratio of 0.035:1 to the partially hydrolyzed and polycondensed silica sol obtained by naturally cooling to room temperature to make the concentration of the partially hydrolyzed and polycondensed silica sol reach 0.01M. Aging sol at ℃ temperature for about 0~16h, then dripping ethanol with a concentration of 99.7% to dilute and let stand for about 5h, then add methyltriethoxysilane, and finally react to form silica sol;

[0055] The molar ratio of the final reagent is tetraethyl orthosilicate (TEOS): ethanol: water: hydrochloric acid: organosilylmethyltriethoxysilane (M...

Embodiment 3

[0064] (1), preparation of silica sol

[0065] SiO 2 Content is 28.4% tetraethyl orthosilicate (TEOS), absolute ethanol, water and pH 2.56 hydrochloric acid molar ratio: 1: 3.8: 1: 5 × 10 -5 Mix, hydrolyze, stir at 60°C for 90 minutes, let the sol cool to room temperature to obtain a partially hydrolyzed and polycondensed silica sol, and let it stand for about 12 hours;

[0066] Add HCl and water with a volume ratio of 0.035:1 to the partially hydrolyzed and polycondensed silica sol obtained by naturally cooling to room temperature to make the concentration of partially hydrolyzed and polycondensed silicon reach 0.01M. Aging sol at high temperature for about 0 to 16 hours, then dripping ethanol with a concentration of 99.7% to dilute and let stand for about 5 hours, then add methyltriethoxysilane, and finally react to form silica sol;

[0067] The molar ratio of the final reagent is tetraethyl orthosilicate (TEOS): ethanol: water: hydrochloric acid: organosilylmethyltriethox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com