Preparation method of SiO2/polymer combined superhydrophobic coating

A super-hydrophobic coating, polymer technology, applied in the direction of coating, can solve problems such as unsuitable large area, and achieve the effects of easy control, cheap raw materials, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

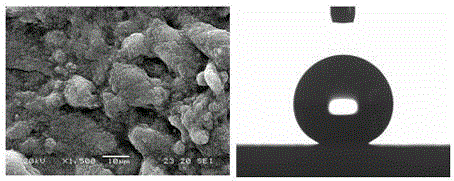

[0022] A SiO 2 The preparation method of the / PS composite superhydrophobic coating is as follows: 1.6g polystyrene is added into 40ml tetrahydrofuran, and magnetically stirred until the polystyrene is completely dissolved to obtain a transparent solution. Then add 2.0 g of DNS-2 nano-silica, ultrasonicate for 0.5 h, then add 1.0 g of γ-mercaptopropyltrimethoxysilane, and continue stirring for 3 h until the nano-silica is uniformly dispersed. Take the glass slide as the substrate, adjust the pulling speed of the vertical pulling machine to 318mm / min, pull to form a film, and let it air at room temperature for 1 hour.

[0023] The resulting SiO 2 The SEM and contact angle photos of / PS composite superhydrophobic coating can be found in figure 1 , the measured contact angle was 168.9±2°.

Embodiment 2

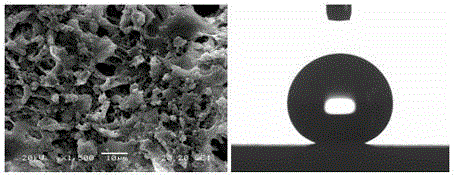

[0025] A SiO 2 The preparation method of the / PVC composite superhydrophobic coating is as follows: 1.6g of polyvinyl chloride is added to 50ml of tetrahydrofuran, and magnetically stirred until the polyvinyl chloride is completely dissolved to obtain a transparent solution. Then add 2.4g of DNS-2 nano-silica, sonicate for 0.5h, then add 1.0g of γ-mercaptopropyltrimethoxysilane, and continue stirring for 3h until the nano-silica is evenly dispersed. Take the glass slide as the substrate, adjust the pulling speed of the vertical pulling machine to 318mm / min, pull to form a film, and let it air for 1 hour at room temperature.

[0026] The resulting SiO 2 / PVC composite superhydrophobic coating SEM and contact angle photos see figure 2 , the measured contact angle was 169.0±2°.

Embodiment 3

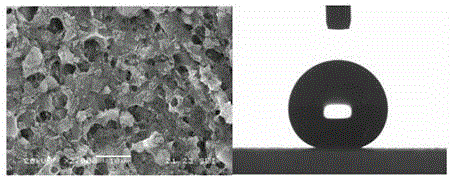

[0028] A SiO 2 / PMMA composite super-hydrophobic coating preparation method, specifically: 1.6g polymethyl methacrylate is added in 40ml tetrahydrofuran, magnetically stirred until the polymethyl methacrylate is completely dissolved, and a transparent solution is obtained. Then add 2.0 g of DNS-2 nano-silica, sonicate for 0.5 h, then add 1.0 g of γ-mercaptopropyltrimethoxysilane, and continue stirring for 3 h until the silica is evenly dispersed. Use filter paper as the base, adjust the pulling speed of the vertical pulling machine to 318mm / min, pull to form a film, and let it air for 1 hour at room temperature.

[0029] The resulting SiO 2 SEM and contact angle photos of PMMA / PMMA composite superhydrophobic coating can be found in image 3 , the measured contact angle was 167.6±2°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com