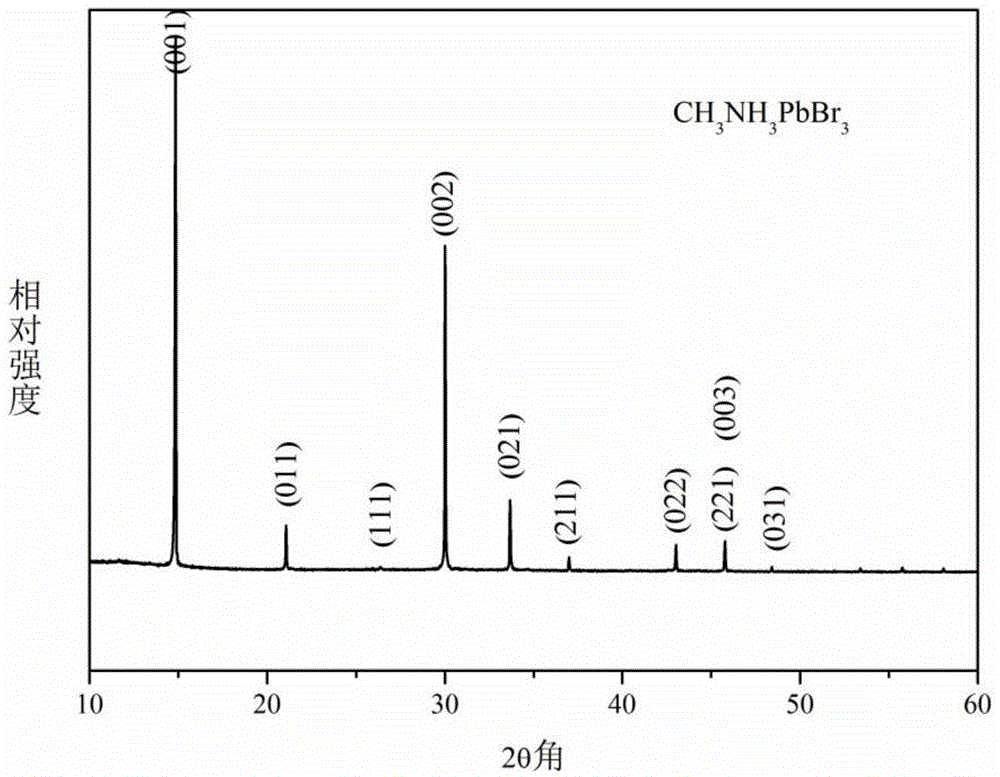

Chemical method for synthesizing perovskite type CH3NH3PbBr3 film material through in-situ large area control based on lead monomer film

A technology of ch3nh3pbbr3 and chemical method, which is applied in the direction of metal material coating process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

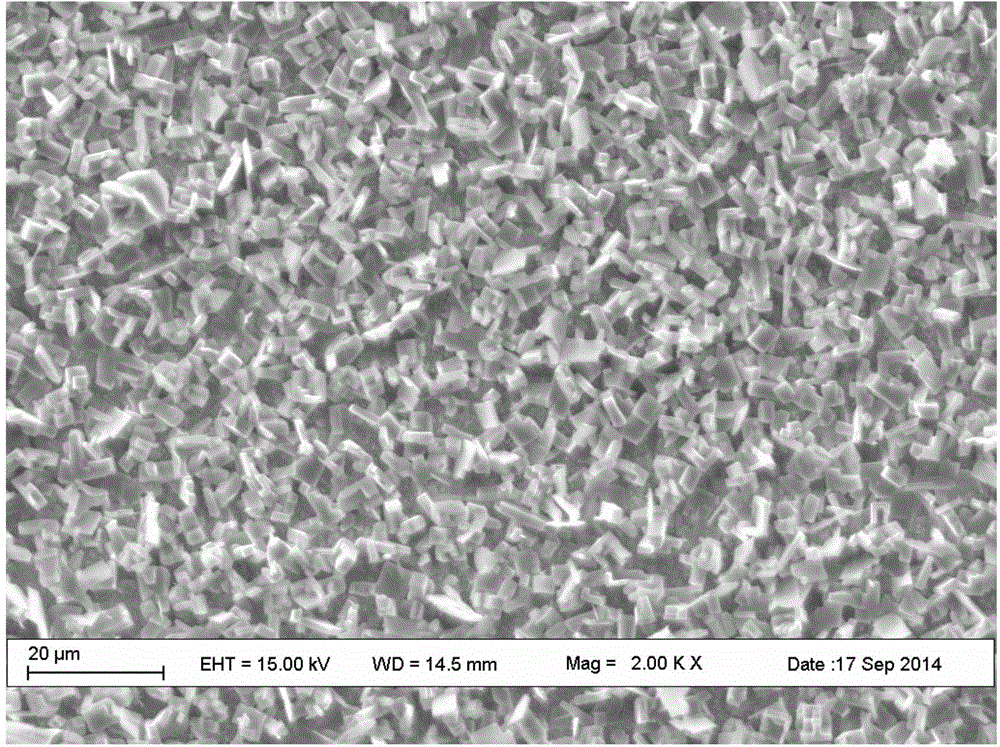

Embodiment 1

[0041] (1) Preparatory work: Put the sailboat brand: CAT.NO.7101, ordinary glass slides in a vacuum of 6~7×10 -3 mbar DC magnetron sputtering a layer of metal lead elemental film with a thickness of about 200nm, and then put it in a desiccator for standby; wash the beaker with tap water and distilled water successively, and dry it for later use;

[0042] (2) Reaction steps: Prepare an anhydrous ethanol solution with a methylamine bromide concentration of 0.0056g / mL in a beaker, then place the beaker in a device with temperature control functions such as a biochemical incubator to keep the temperature at 25°C, and put the Put the glass substrate on the surface of the lead elemental film into the reaction solution, and react at 25°C for 1 hour;

[0043] (3) Post-treatment: After the reaction, close the biochemical incubator, take out the sample, and dry it in a blast drying oven at 70°C. Will get CH 3 NH 3 PbBr 3 Film material samples are carefully transferred to sample vial...

Embodiment 2

[0045] (1) Preparatory work: Put the sailboat brand: CAT.NO.7101, ordinary glass slides in a vacuum of 6~7×10 -3mbar DC magnetron sputtering a layer of metal lead elemental film with a thickness of about 200nm, and then put it in a desiccator for standby; wash the beaker with tap water and distilled water successively, and dry it for use;

[0046] (2) Reaction steps: Prepare an anhydrous ethanol solution with a methylamine bromide concentration of 0.0056g / mL in a beaker, and then place the beaker in a device with temperature control functions such as a biochemical incubator to keep the temperature at 25°C. Put the glass substrate on the surface of the lead element film into the reaction solution, and react at 25°C for 1.5 hours;

[0047] (3) Post-treatment: After the reaction, close the biochemical incubator, take out the sample, and dry it in a blast drying oven at 70°C. Will get CH 3 NH 3 PbBr 3 Film material samples are carefully transferred to sample vials and stored i...

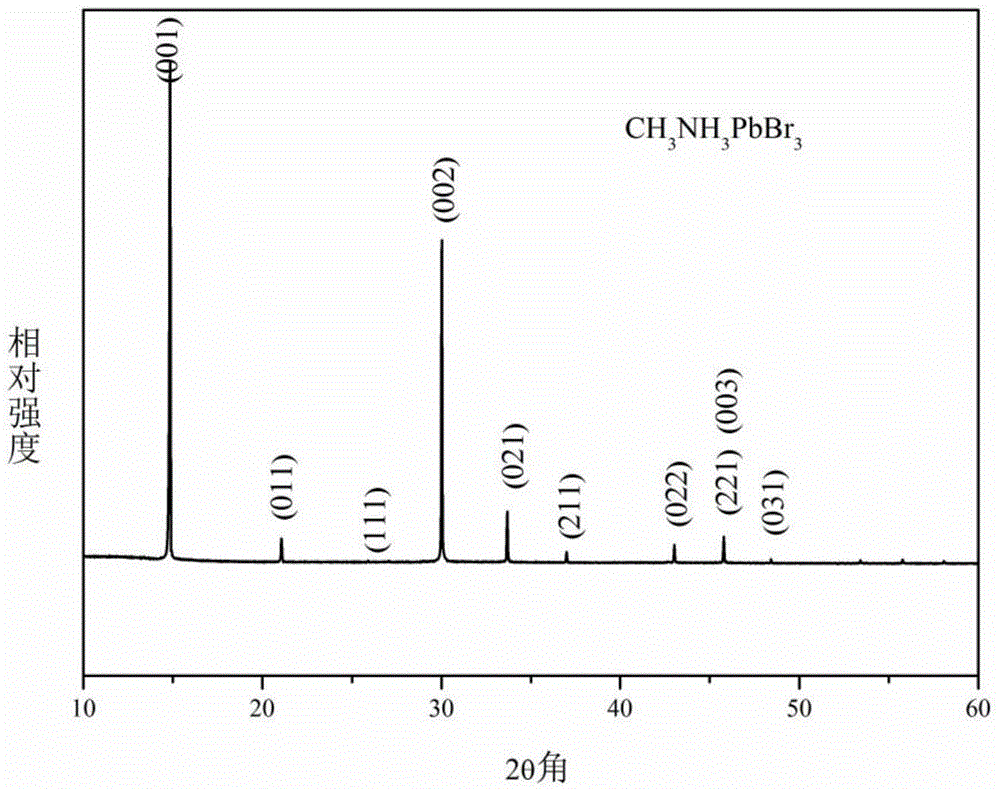

Embodiment 3

[0049] (1) Preparatory work: Put the sailboat brand: CAT.NO.7101, ordinary glass slides in a vacuum of 6~7×10 -3 mbar DC magnetron sputtering a layer of metal lead elemental film with a thickness of about 200nm, and then put it in a desiccator for standby; wash the beaker with tap water and distilled water successively, and dry it for use;

[0050] (2) Reaction steps: Prepare an anhydrous ethanol solution with a methylamine bromide concentration of 0.0056g / mL in a beaker, and then place the beaker in a device with temperature control functions such as a biochemical incubator to keep the temperature at 25°C. Put the glass substrate on the surface of the lead elemental film into the reaction solution, and react at 25°C for 2.5 hours;

[0051] (3) Post-treatment: After the reaction, close the biochemical incubator, take out the sample, and dry it in a blast drying oven at 70°C. Will get CH 3 NH 3 PbBr 3 Film material samples are carefully transferred to sample vials and store...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com