High-temp. superconducting film conductor and preparing method thereof

A high-temperature superconducting and film-coating technology, applied in superconducting/high-conducting conductors, usage of superconducting elements, cable/conductor manufacturing, etc., can solve problems such as no successful reports and increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

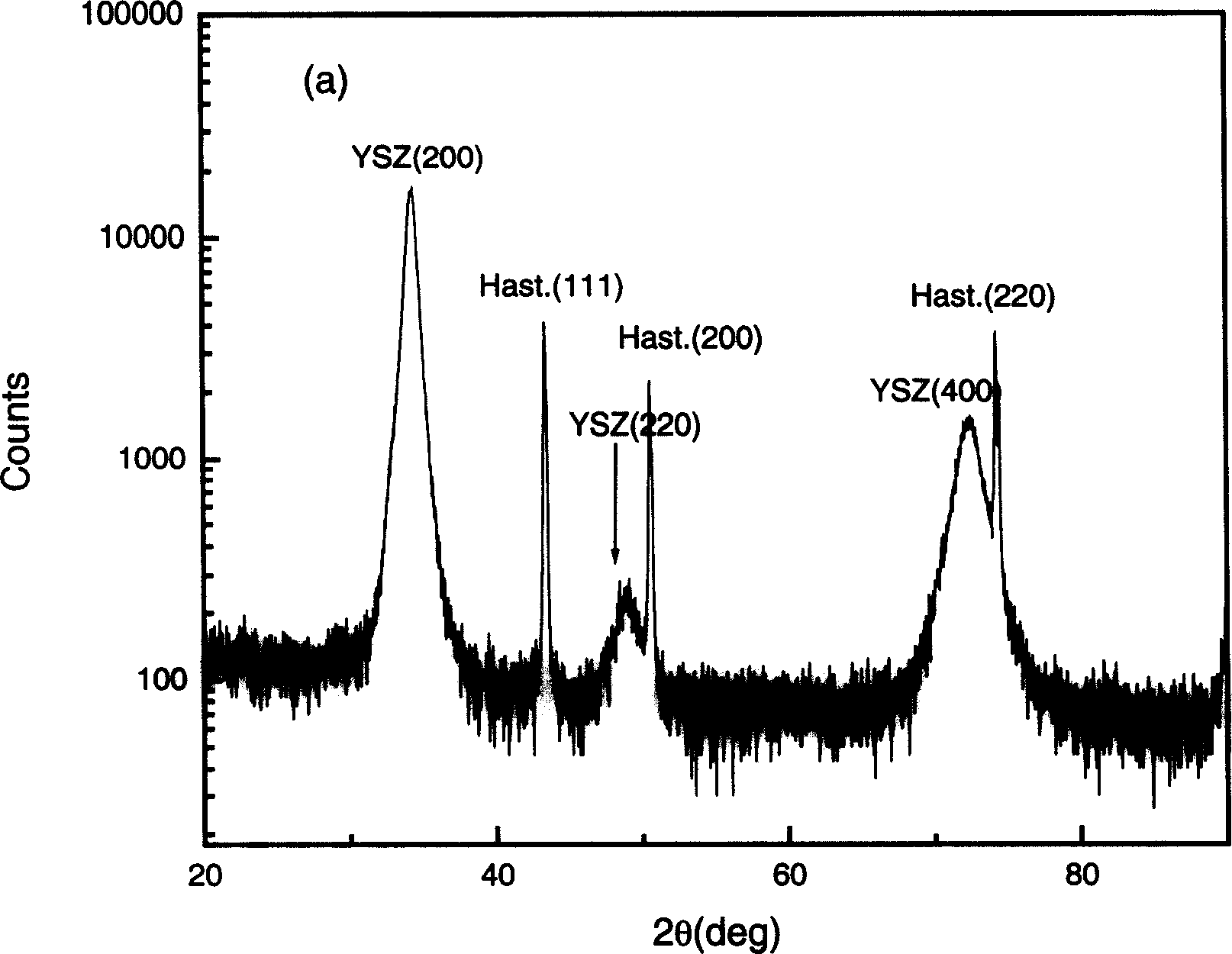

[0044] Sequential preparation of CeO on IBAD YSZ / Hast. substrates by an all-chemical solution method 2 Buffer layer and YBCO superconducting layer film. The final quench protection layer is prepared by magnetron sputtering technology.

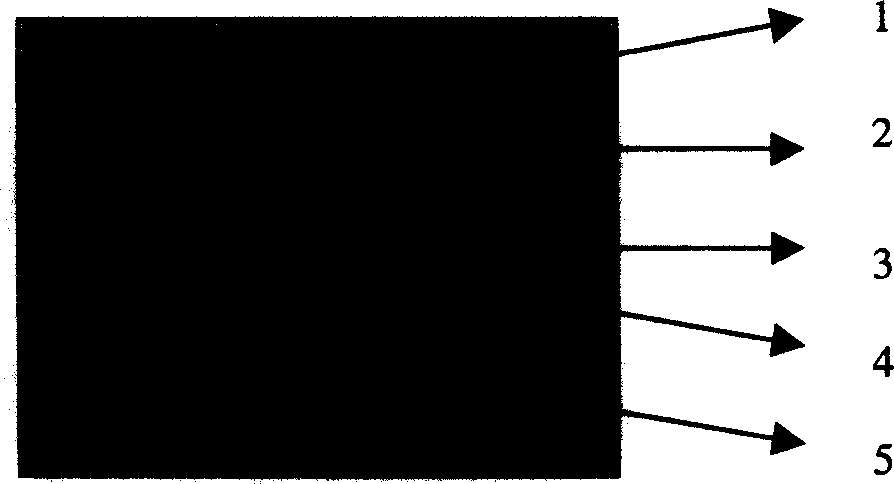

[0045] figure 1 : Schematic diagram of the cross-sectional structure of a high-temperature superconducting film-coated conductor. Among them: 1. Superconducting protective layer; 2. YBCO superconducting layer; 3. CeO 2 Buffer layer; 4. IBAD YSZ buffer layer; 5. Hastelloy metal substrate.

[0046] The superconducting protective layer is prepared by the conventional magnetron sputtering method; the YBCO superconducting layer is prepared by the TFA-MOD process, and the specific process is as follows:

[0047] 1) Prepare a YSZ buffer layer (commercially available) on a Hastelloy substrate using an IBAD process;

[0048] 2) Prepare CeO on the substrate described in 1) 2 The buffer layer;

[0049] CeO 2 The buffer layer is prepared by chemica...

Embodiment 2

[0066] Sequential preparation of CeO on IBAD YSZ / Hast. substrates by an all-chemical solution method 2 Buffer layer and YBCO superconducting layer film. The final quench protection layer is prepared by magnetron sputtering technology.

[0067] figure 1 : Schematic diagram of the cross-sectional structure of the high-temperature superconducting film-coated conductor.

[0068] Among them: 1. Superconducting protective layer; 2. YBCO superconducting layer; 3. CeO 2 Buffer layer; 4. IBAD YSZ buffer layer; 5. Hastelloy metal substrate.

[0069] The superconducting protective layer is prepared by the conventional magnetron sputtering method; the YBCO superconducting layer is prepared by the TFA-MOD process, and the specific process is as follows:

[0070] 1) Prepare a YSZ buffer layer (commercially available) on a Hastelloy substrate using an IBAD process;

[0071] 2) Prepare CeO on the substrate described in 1) 2 The buffer layer;

[0072] CeO 2 The buffer layer is prepared...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average roughness | aaaaa | aaaaa |

| Critical current density | aaaaa | aaaaa |

| Critical current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com