Boiling resistant polyurethane adhesive and method for preparing same

A polyurethane adhesive and cooking-resistant technology, which is applied in polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problem of not considering the deep freezing resistance of adhesives, poor low temperature performance, and failure to meet application requirements, etc. Problems, to achieve the effect of excellent resistance to chemical media, high adhesive strength, and excellent low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Put 166g of isophthalic acid, 202g of sebacic acid, 225g of 2-methylpropanediol, 26.8g of trimethylolpropane and 100ppm of catalyst stannous chloride into a 1000ml three-necked flask reactor, under nitrogen protection at 160-220 °C to react until the hydroxyl value of the system is less than 10mgKOH / g, and then gradually reduce the pressure at 220-240°C to continue the reaction to obtain a polyester polyol product with a hydroxyl value of 80mgKOH / g. Ethyl acetate was added to dissolve to 49% solids and labeled "B1".

Embodiment 2

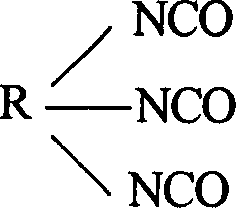

[0036] Put 522.6g of toluene diisocyanate (TDI) and 219g of ethyl acetate into a three-neck flask reactor, control the temperature of the reactant between 60-80°C, add 134g of molten trimethylolpropane (TMP) dropwise, and add dropwise The reaction was continued for 4.5 hours after completion to obtain a curing agent for polyurethane dry composite adhesive with an isocyanate group content of 14.4% and a solid content of 75%, which was labeled as "curing agent 1".

Embodiment 3

[0038] Put 83g of terephthalic acid, 166g of isophthalic acid, 124g of ethylene glycol, 156g of neopentyl glycol and 100ppm of catalyst stannous chloride into a 1000ml three-neck flask reactor, and react at 160-220°C under nitrogen protection until water yield After reaching 54g, add 202g of sebacic acid and 200g of polytetrahydrofuran with a relative molecular weight of 1000, continue the reaction at 200-230°C until the water is exhausted, and then gradually reduce the pressure at 200-230°C for 4 hours, and finally at 1-2mmHg The reaction was continued for 4 hours at 230-250° C. in a vacuum, the reaction was stopped, and the temperature of the reaction system was lowered. The hydroxyl value of the obtained polyether ester diol product was 11.2 mgKOH / g. Ethyl acetate was added to dissolve to 49% solids, labeled "A1".

[0039] Add 3 parts of A1 and 1 part of B1, and add 1% by mass of KH-560 coupling agent and mix thoroughly to obtain the main component of polyurethane adhesive,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com