Modified inorganic nano particle, composite waterborne polyurethane resin and application thereof

A technology of inorganic nanoparticles and water-based polyurethane, applied in the field of polymers, can solve the problems of affecting molecular weight, poor compatibility, destroying the growth of polyurethane molecular chains, etc., to achieve excellent mechanical properties and improve comprehensive properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

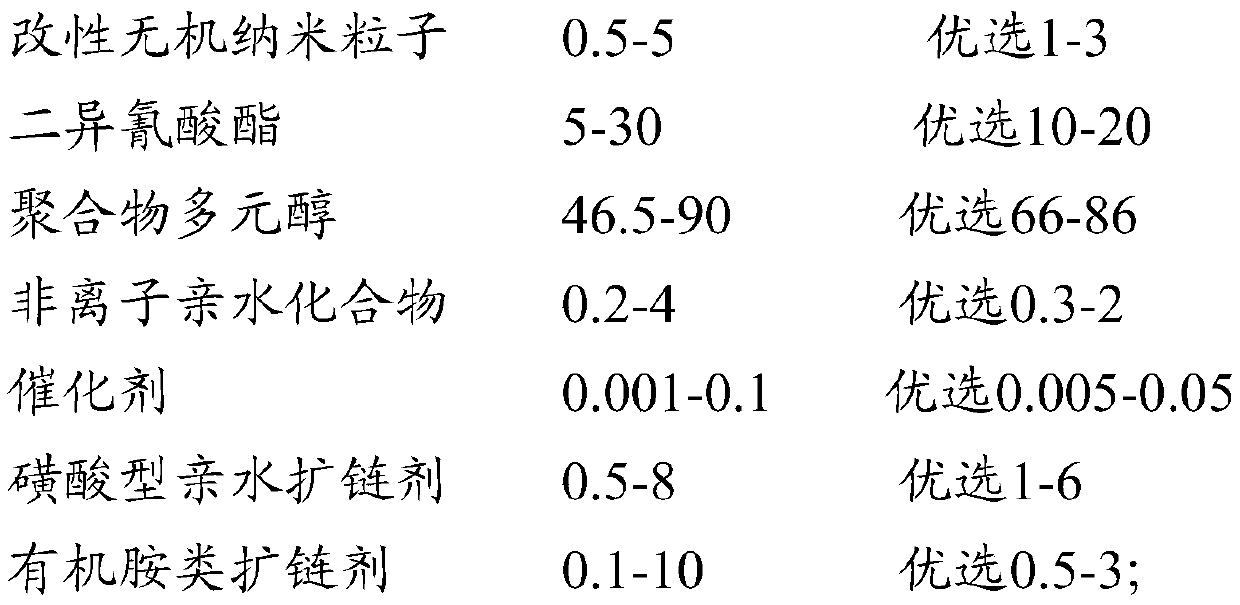

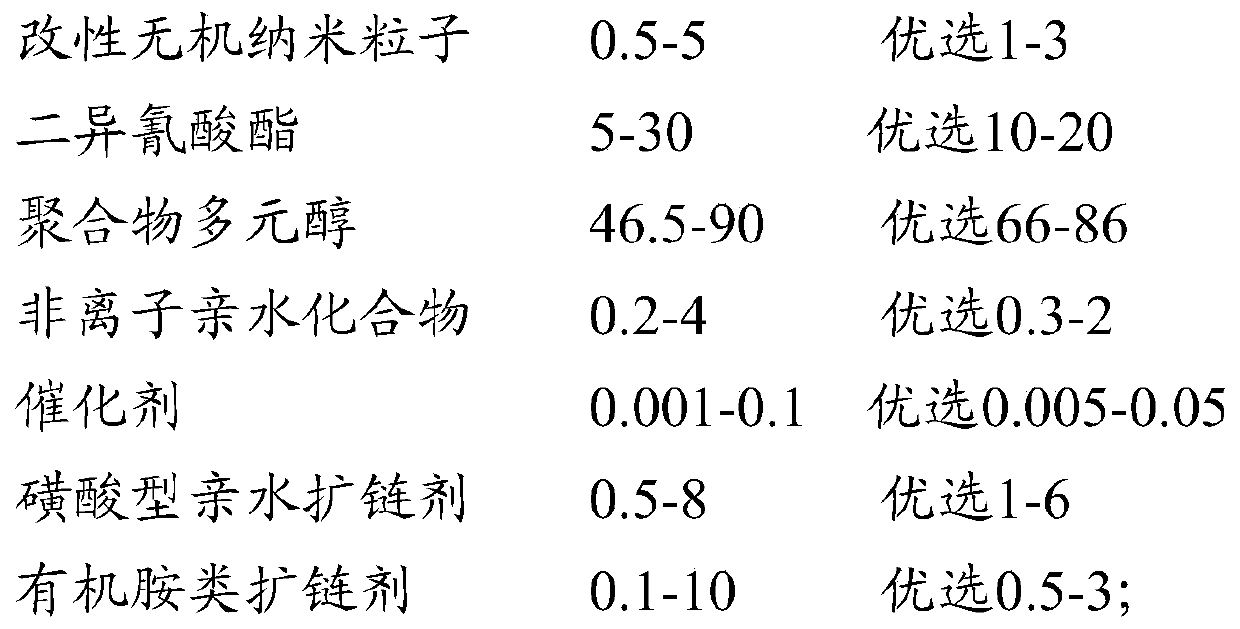

Method used

Image

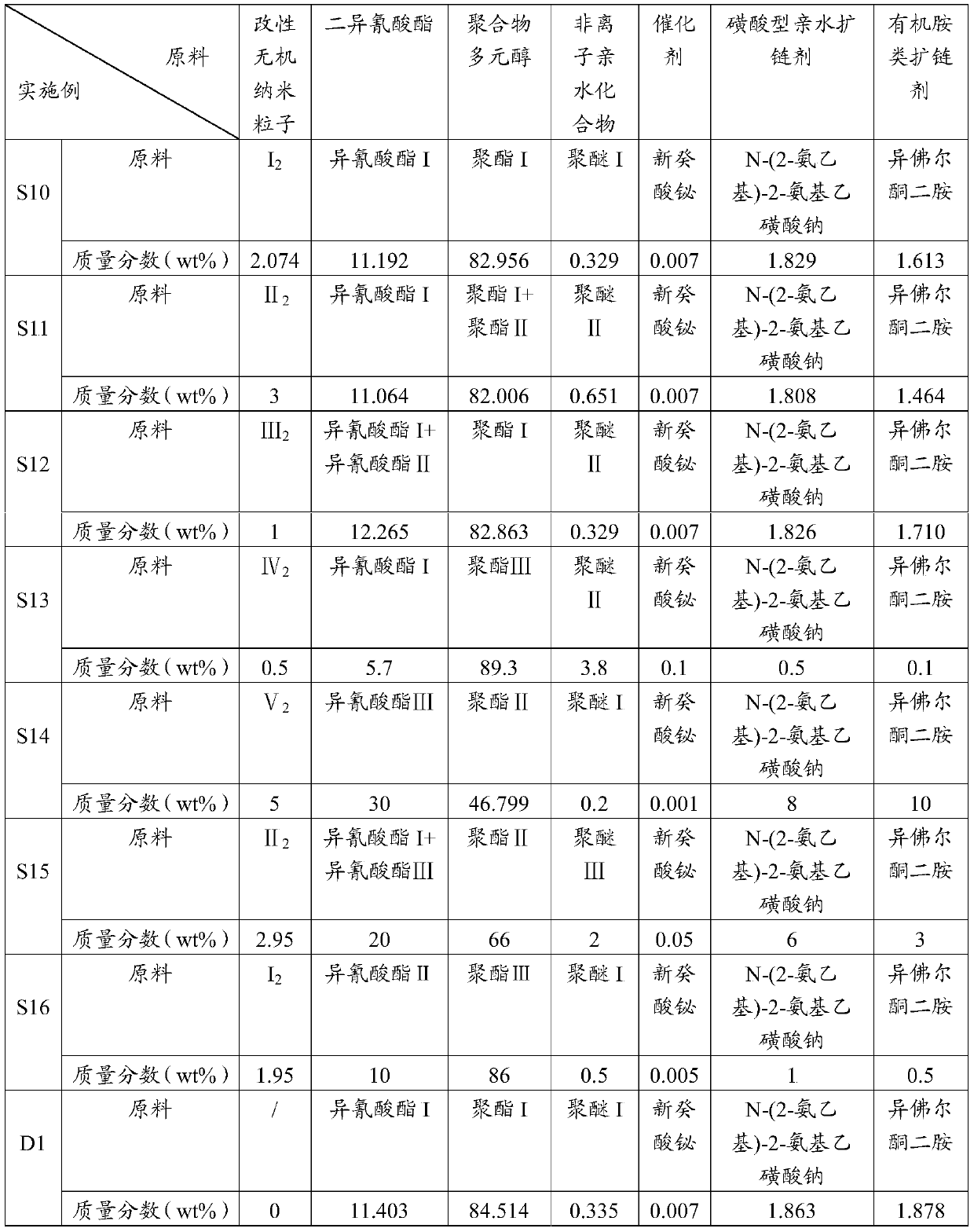

Examples

Embodiment 1

[0092] Embodiment 1 (abbreviated as S1)

[0093] 3.66g Tetrafluorooctyl methacrylate and 1.67g N-β-(aminoethyl)-γ-aminopropyltrimethoxysilane are mixed and added in 50ml ethanol solvent, and N 2 , fully stirred and reacted at room temperature for 24 hours, and then distilled off ethanol under reduced pressure at 65°C to obtain fluorine-containing polyaminosilane coupling agent I 1 .

Embodiment 2

[0094] Embodiment 2 (abbreviated as S2)

[0095] 3.95g hexadecafluorononyl methacrylate and 1.98g N-β-(aminoethyl)-γ-aminopropyltriethoxysilane were mixed and added to 50ml ethanol solvent, and N 2 , fully stirred and reacted at room temperature for 28 hours, and then distilled off ethanol under reduced pressure at 65°C to obtain fluorine-containing polyaminosilane coupling agent II 1 .

Embodiment 3

[0096] Embodiment 3 (abbreviated as S3)

[0097] Mix 4.14g octadecadecanyl fluorodecyl methacrylate and 1.98g N-β-(aminoethyl)-γ-aminopropyltriethoxysilane into 50ml of ethanol solvent, and feed N 2 , fully stirred and reacted at room temperature for 36 hours, and then distilled off ethanol under reduced pressure at 65°C to obtain fluorine-containing polyaminosilane coupling agent III 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com