Hot-melt polyurethane adhesive with high initial adhesion and preparation method thereof

A technology of hot-melt polyurethane and high initial viscosity, which is applied in the field of high initial viscosity hot-melt polyurethane adhesive and its preparation, which can solve the problems of inapplicable initial adhesive requirements and achieve the effect of high initial adhesive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

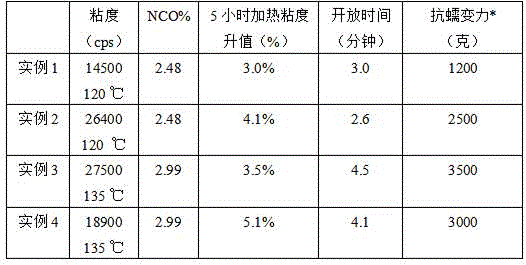

Examples

Embodiment Construction

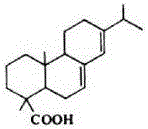

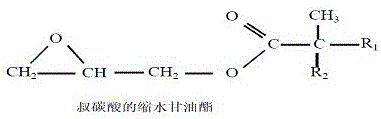

[0044] The preparation method of the modified rosin acid active tackifier containing hydroxyl group is as follows: put the refined rosin or hydrogenated rosin in the market, glyceryl tert-carbonate Cardura EP10 (or other high-boiling compounds containing epoxy) in the reaction at a molar ratio of 1:1.05 Heating in the kettle to 2200C, dehydration reaction for about 20 hours until the acid acid is less than 0.5. Nitrogen protection was used during the reaction and a high vacuum was used for rapid dehydration. After the reaction is completed, the material is discharged in a molten state for use. The state of the product is a highly viscous liquid (or high Tg solid), and the active viscosifier in the example is the above-mentioned high viscous liquid viscosifier. The difference from the comparative patent is that the former uses a polymer active tackifier formed by free radical polymerization, with a molecular weight between 5000-32000; while the active tackifier in the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com