Primer coating for polyurethane sealant and preparation method thereof

A polyurethane sealant and primer technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of long waiting time, narrow use range, slow curing speed, etc., to reduce waiting time, improve production efficiency, fast curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] Weigh 50-70 parts by mass of polyol and 5-10 parts of non-reactive thermoplastic resin, adjust the temperature to 130°C to melt, and dry the melt for 45 minutes under the condition of less than 10mba; in protective gas (dry nitrogen or In the presence of carbon dioxide), add a certain amount of polyisocyanate and melt it uniformly, react at 110~130°C for 30~45min, until the isocyanate content is 2~5%; then add 5~15 parts by mass of silane compound, mix well, Finally, 10-20 parts by mass of polyisocyanate is added, mixed evenly, and reacted for 15-25 minutes to obtain a quick-drying solid primer with high initial bonding strength for polyurethane sealants.

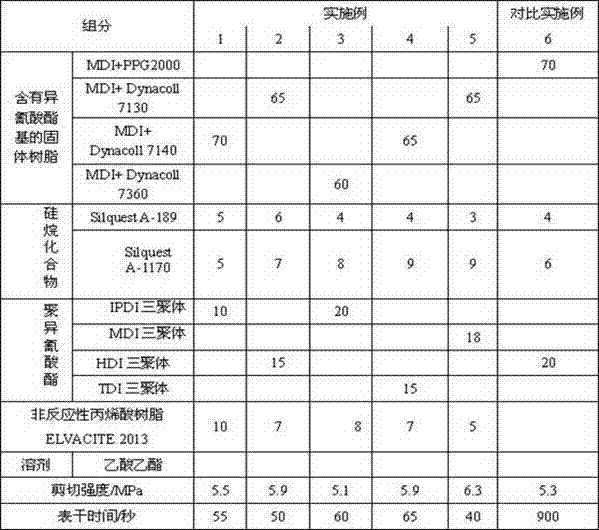

[0026] The molar ratio of the polyhydroxy compound to the polyisocyanate compound is 1: 2.1 to 2.3; according to the above primer manufacturing process, the following 1-5 examples are obtained, as shown in Table 1. The following examples can further illustrate the present invention , but does not limit the invention....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com