Single-component silane modified polyether sealant used in automobile glass rapid assembling, and preparation method thereof

A technology of silane-modified polyether and automotive glass, which is applied in the direction of polyether adhesives, adhesives, adhesive types, etc., and can solve the problem of insufficient initial bonding strength and poor operation convenience of silane-modified polyether sealants Improve production assembly efficiency, fast bonding and positioning, and save operating time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

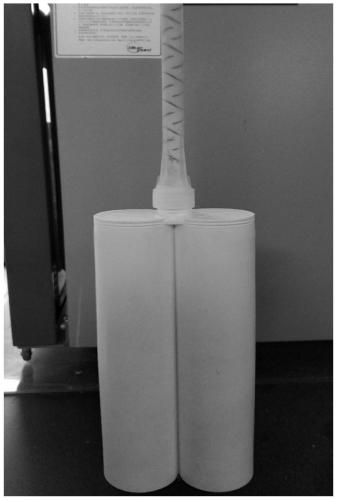

Image

Examples

Embodiment 1

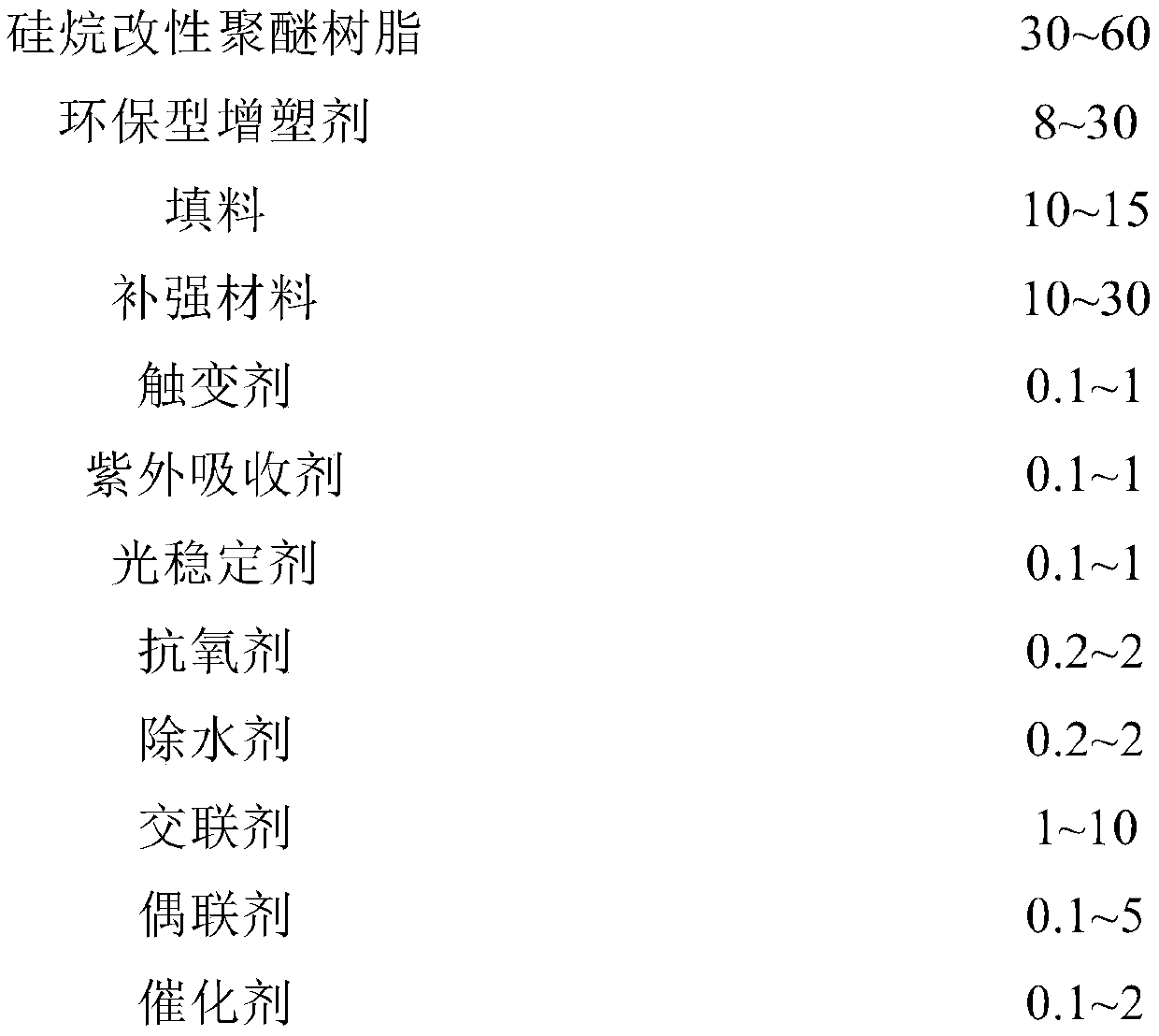

[0044] The parts by weight ratio of the components of Example 1 is shown in Table 1:

[0045] Table 1

[0046]

[0047] Preparation

[0048] (1) dry nano-calcium carbonate and high specific surface carbon black at 120 ℃ for 3 hours, and set aside;

[0049] (2) Add S303H, SAX530, phenyl alkylsulfonate, polyamide wax, nano-calcium carbonate, high specific carbon black and vinyltrimethoxysilane with a mass fraction of 20% in sequence to the planetary kettle, and disperse at high speed for 30 minutes~ 40min; then stir for 20min~30min under the condition of vacuum degree of -0.09MPa~-0.1MPa;

[0050] (3) Add Tinuvin 326, Tinuvin 770, Irganox 1010, ethyl orthosilicate, 80% by mass of vinyltrimethoxysilane and dibutyltin bis(acetylacetonate) are mixed evenly, stirred for 20min to 40min under the condition of vacuum degree of -0.09MPa~-0.1MPa, and then discharged.

Embodiment 2

[0052] The parts by weight ratio of the components of Example 2 is shown in Table 2:

[0053] Table 2

[0054]

[0055] Preparation

[0056] (1) dry nano-calcium carbonate and high specific surface carbon black at 120 ℃ for 3 hours, and set aside;

[0057] (2) Add SAX400, SAX580, phenyl alkylsulfonate, polyamide wax, nano-calcium carbonate, high specific carbon black and vinyltrimethoxysilane with a mass fraction of 20% in sequence to the planetary kettle, and disperse at a high speed for 30 minutes~ 40min; then stir for 20min~30min under the condition of vacuum degree of -0.09MPa~-0.1MPa;

[0058] (3) Add Tinuvin 326, Tinuvin 770, Irganox 1010, ethyl orthosilicate, N-β-(aminoethyl)-γ-aminopropylmethyldimethoxysilane, γ-glycidyl ether oxypropyl Trimethoxysilane, 80% by mass of vinyltrimethoxysilane and dibutyltin bis(acetylacetonate) were mixed uniformly, and stirred for 20min to 40min under the condition of vacuum degree of -0.09MPa~-0.1MPa, Ready to go.

Embodiment 3

[0060] The parts by weight ratio of the components of embodiment 3 is as follows in table 3:

[0061] table 3

[0062]

[0063] Preparation

[0064] (1) dry nano-calcium carbonate and high specific surface carbon black at 120 ℃ for 3 hours, and set aside;

[0065] (2) Add SAX400, SAX580, cyclohexane 1,2-diisononyl dicarboxylate, polyamide wax, nano-calcium carbonate, high specific carbon black and 20% vinyl trimethoxy in the planetary kettle in sequence Base silane, disperse at high speed for 30min~40min; then stir for 20min~30min under the condition of vacuum degree of -0.09MPa~-0.1MPa;

[0066] (3) Add Tinuvin 326, Tinuvin 770, Irganox 1010, ethyl orthosilicate, 80% by mass of vinyltrimethoxysilane and dibutyltin bis(acetylacetonate) are mixed evenly, stirred for 20min to 40min under the condition of vacuum degree of -0.09MPa~-0.1MPa, and then discharged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com