A kind of modified terminal silane polyether sealant and preparation method thereof

A silane-terminated polyether and sealant technology, applied in the field of sealants, can solve the problems of lower elongation at break of elastomers, poor toughness of sealants, etc., and achieve the effects of good strength and toughness, fast bonding and positioning, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

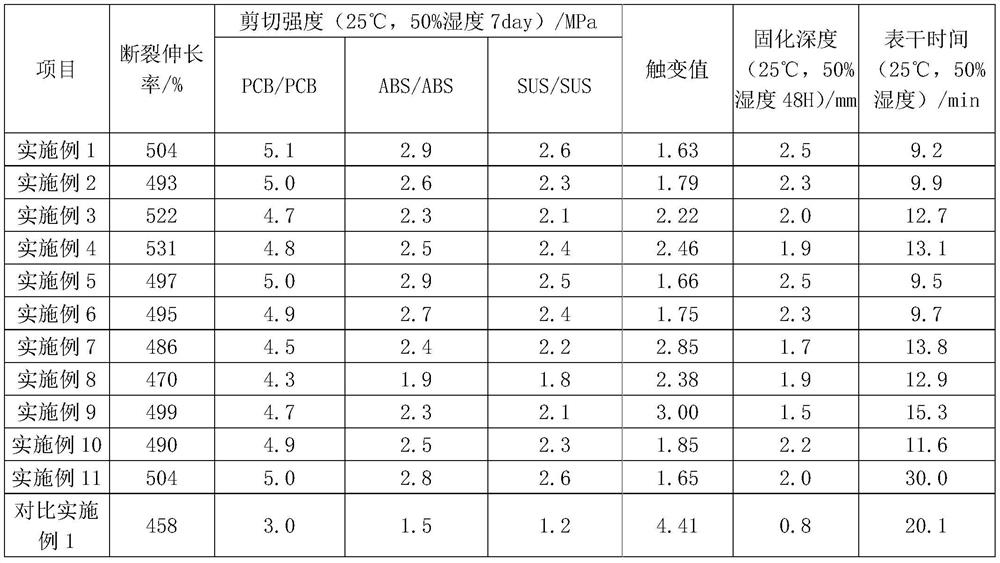

Examples

preparation example 1

[0040] S1. Take dry 100 parts of light calcium carbonate with an average particle size of 1.8 μm and add it to a ball mill, stir and preheat to a temperature of 60°C, add 1.5 parts of 3-(2,3 glycidoxypropyl) trimethoxy Modified solution prepared by silane, 15 parts of ethanol and 1.5 parts of water, stirred evenly, dried for later use;

[0041] S2. the mol ratio of calcium carbonate obtained in step S1, 1.86 parts of polyetheramine T403 (i.e. 3-(2,3 glycidoxypropyl) trimethoxysilane and polyetheramine T403 of BASF, Germany) to polyetheramine T403 is 1.5:1 ), 0.3 parts of triethanolamine were mixed evenly according to the proportion, and the air bubbles in the mixture system were removed by centrifugation, placed in a drying oven, and reacted at 80°C / 2h+125°C / 2h to obtain modified calcium carbonate.

preparation example 2

[0043] The rest is the same as Preparation Example 1, except that the amount of polyetheramine T403 is 2.33 parts, that is, the molar ratio of epoxy silane coupling agent to polyetheramine T403 is 1.2:1.

preparation example 3

[0045] The rest is the same as Preparation Example 1, except that the amount of polyetheramine T403 is 1.4 parts, that is, the molar ratio of epoxy silane coupling agent to polyetheramine T403 is 2:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com