Double-component aqueous neoprene spray glue

A two-component, neoprene latex technology, applied in the field of decoration, can solve the problems of unsatisfactory production operation, limited use range, low market profit, etc., and achieve the effect of convenient construction, low cost and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

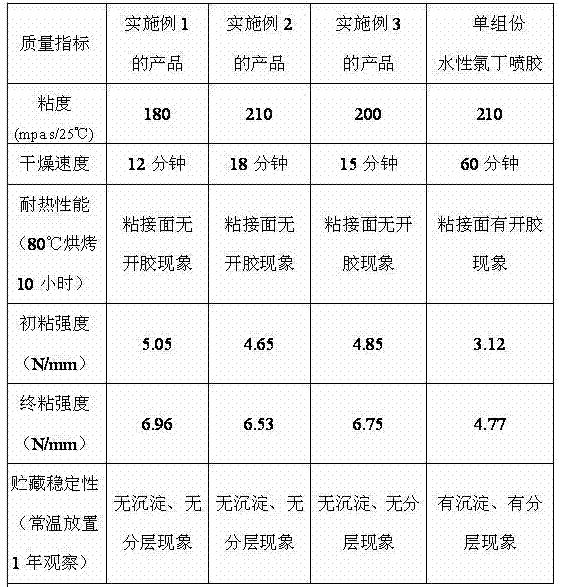

Examples

Embodiment 1

[0027] A two-component water-based neoprene spray glue, comprising the following steps:

[0028] Step 1: First take 100 grams of neoprene emulsion, 30 grams of polyurethane emulsion, 40 grams of polymethylacrylate emulsion, 45 grams of water-based terpene phenolic resin, 2 grams of zinc oxide, 3 grams of silicon dioxide, SD1688 Dissolve 4 grams of anti-aging agent in 100 grams of deionized water, disperse at a speed of 400 r / min, and disperse for 100 minutes, and disperse evenly to obtain a composite emulsion.

[0029] Step 2: Add 45 grams of water-based rosin resin, 0.2 grams of 5-chloro-2-methyl-4-isothiazolin-3-one, 0.5 grams of hydroxyethyl cellulose, and 1 gram of phenylbenzotriazole and other additives, the dispersion speed is 300r / min, the dispersion time is 120 min, and the dispersion is uniform, that is, the finished product of water-based neoprene spray glue is obtained.

[0030] When spraying, add 15 grams of water-based curing agent to 100 grams of water-based neo...

Embodiment 2

[0032] Step 1: first get 110 grams of neoprene emulsion, 35 grams of polyurethane emulsion, 30 grams of polymethyl acrylate emulsion, 40 grams of water-based alkylphenolic resin, 2.5 grams of zinc oxide, 3 grams of silicon dioxide, KY616 Dissolve 4.5 grams of anti-aging agent in 110 grams of deionized water, disperse at a speed of 800 r / min, and disperse for 90 minutes, and disperse evenly to obtain a composite emulsion.

[0033] Step 2: Add 40 grams of water-based rosin resin, 0.3 grams of 2-methyl-4-isothiazolin-3-one, 0.6 grams of polyacrylate, and 0.6 grams of hydroxyphenylbenzotriazepam into the composite emulsion of step (1). 1.2 grams of azole and other additives, dispersion speed 500r / min, dispersion time 90 minutes, uniform dispersion, that is, the finished product of water-based neoprene spray glue.

[0034] When spraying, add 18 grams of water-based curing agent to 120 grams of water-based neoprene spray glue, stir well, and use immediately.

Embodiment 3

[0036] Step 1: First take 120 grams of neoprene emulsion, 45 grams of polyurethane emulsion, 35 grams of polymethylacrylate emulsion, 55 grams of water-based rosin resin, 2 grams of zinc oxide, 3 grams of silicon dioxide, SD1688 anti-aging agent Dissolve 4.0 grams in 120 grams of deionized water, disperse at a speed of 1000 r / min, and disperse for 60 minutes, and disperse evenly to obtain a composite emulsion.

[0037] Step 2: Add 55 grams of water-based rosin resin, 0.5 grams of water-based nano-magnesium oxide, 0.3 grams of sodium polyacrylate dispersant, 1 gram of hydroxyphenyl benzotriazole and other additives to the composite emulsion of step (1) to disperse The speed is 800r / min, the dispersion time is 90 minutes, and the dispersion is uniform, that is, the finished product of water-based neoprene spray glue is obtained.

[0038] When spraying, add 20 grams of water-based curing agent to 120 grams of water-based neoprene spray glue, stir well, and use immediately.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com