Thermal-resistant PVC (Polyvinyl Chloride) composite double-component polyurethane adhesive and preparation method thereof

A two-component polyurethane and adhesive technology, applied in the field of polyurethane materials, can solve the problems of peeling decline, poor heat resistance, degumming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

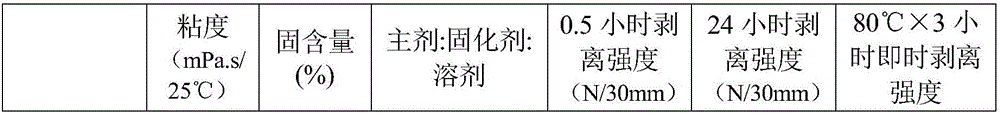

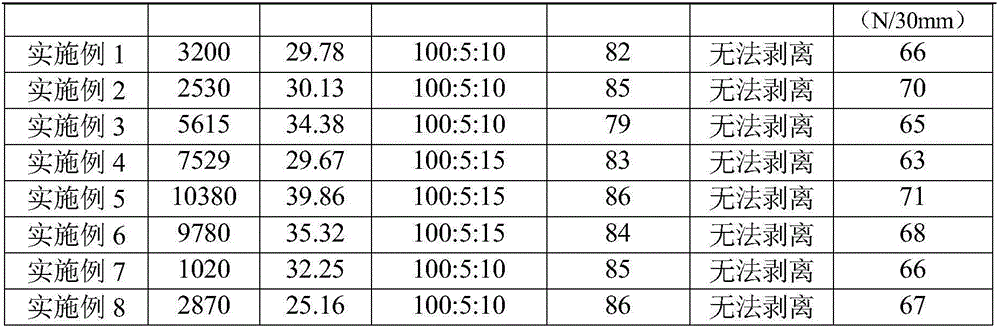

Examples

preparation example Construction

[0011] The preparation method of this heat-resistant type PVC composite two-component polyurethane adhesive can be the following steps:

[0012] (1) Preparation of polyester polyol: under the action of composite catalyst B, dibasic acid and polyol are subjected to polyesterification reaction at 140°C-250°C under the protection of nitrogen, until the acid value is reduced to below 1mgKOH / g , stop the reaction when the hydroxyl value is 30-200mgKOH / g, and obtain polyester polyol;

[0013] (2) Preparation of the main adhesive agent: dissolve the hydroxychloride resin in part of the solvent, add the polyester polyol, chain extender, and isocyanate prepared in step (1) into the reaction kettle, and heat up to 50-80°C Fully react; then add part of the solvent to dilute, add the remaining isocyanate in batches until the viscosity meets the requirements; finally add small molecule polyol and the remaining solvent to terminate the reaction, cool to 35-40°C and discharge;

[0014] (3) ...

Embodiment 1

[0017] 1. Preparation of polyester polyol 1:

[0018] Mix 822gAA, 385gEG and 5g catalyst tetraisobutyl titanate, heat to 210°C under the protection of nitrogen for polyesterification reaction, react for 18Hr, stop the reaction when the acid value is 0.3mgKOH / g, and the hydroxyl value is 56mgKOH / g. 960g polyester polyol.

[0019] Two, prepare polyester polyol 2:

[0020] Mix 370gAA, 247gPTA, 160gEG, 370gDEG and 5g catalyst tetraisobutyl titanate, heat to 240°C under nitrogen protection for polyesterification reaction, react for 20Hr, when the acid value is 0.3mgKOH / g, and the hydroxyl value is 225mgKOH / g The reaction was stopped to obtain 960 g of polyester polyol.

[0021] 3. Prepare the main agent of polyurethane adhesive:

[0022] (1) Take 20g of hydroxychloride resin, mix it with 40g of MEK (butanone), stir and dissolve it, put it into the reaction kettle together with 150g of prepared polyester polyol 1 and 20g of polyester polyol 2, and slowly heat to 50 °C, stir to m...

Embodiment 2

[0029] 1. Preparation of polyester polyol 3:

[0030] Mix 697gAA, 476gBG and 5g catalyst tetraisobutyl titanate, heat to 220°C under the protection of nitrogen for polyesterification reaction, react for 16Hr, stop the reaction when the acid value is 0.3mgKOH / g, and the hydroxyl value is 56mgKOH / g. Polyester polyol 961g.

[0031] Two, prepare the main agent of polyurethane adhesive:

[0032] (1) get 20g hydroxychloride resin, mix homogeneously with 40g MEK (butanone), after stirring and dissolving, drop into the reactor together with the polyester polyol 3 prepared by 145g, the polyester polyol 2 prepared by 25g embodiment 1, Slowly heat to 50°C and stir to make it evenly mixed.

[0033] (2) Put in 22g of MDI, heat up to 75°C, and react for 1 hour.

[0034] (3) Add 0.03g of dibutyltin dilaurate as a catalyst, add 12.5gMDI, 160gETAC (ethyl acetate), and 325gMEK (butanone) in batches according to its viscosity, and adjust the viscosity to 2530mPa.s / 25°C

[0035] (4) Add 0.5g ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com