Quick manufacturing method for die-free casting sand mold

A manufacturing method and rapid technology, applied in the directions of casting molds, casting mold components, manufacturing tools, etc., can solve problems such as large gas generation of casting molds, and achieve the effects of saving energy, reducing deformation, and reducing usage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

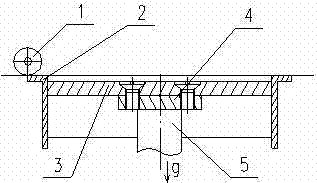

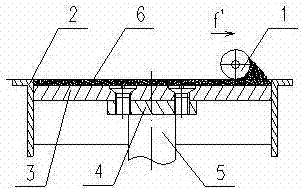

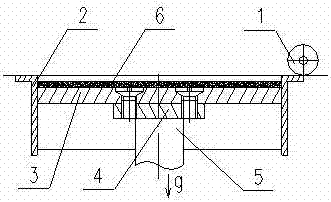

[0045] Such as Figure 1 to Figure 14 As shown in the figure, a rapid manufacturing method for moldless molds is adopted. The computer controls the existing powder spreading system in the moldless sand mold manufacturing equipment. The contour data information command of each layer section, the spraying system of the driving equipment sprays the solvent, the sprayed part of the phenolic resin coated sand is melted, bonded and formed, after the first layer is formed after drying, the workbench is lowered by one layer, and then The second layer of powdering, spraying solvent absolute ethanol, the phenolic resin coated sand sprayed with solvent absolute ethanol is melted, bonded and formed, dried until finally stacked and solidified into a molded entity, and the remaining residue that has not been melted is removed. sand, and dried and solidified to obtain a high-strength mold.

[0046] Take the 8-shaped test block as an example, the steps are as follows:

[0047] Step 1: Lay t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com