High initial strength filling mining method

A technology of initial strength and filling coal mining, which is applied in the direction of filling, ground mining, mining equipment, etc., can solve the problems of difficult sources of coal mine filling and mining materials, and achieve the effect of high initial strength, low cost and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0027] 1) Pick out and recycle the unbreakable scrap metal in the urban garbage, and use a crusher to crush the remaining part into particles with a particle size of less than 30mm;

[0028] 2) Add a certain amount of curing agent to the crushed garbage particles and stir evenly, then introduce the stirred mixture into a pressing mold to make a filling profile (6) of a certain size, and the strength of the filling profile (6) is not less than that of the mined The strength of the coal seam, after the pressing is completed, the surface is encapsulated, and the pressed leachate is treated separately;

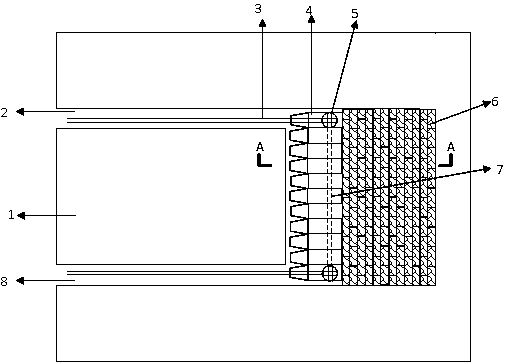

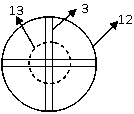

[0029] 3) Filling profile (6) filling in the goaf of the coal mine: first, select the deep shaft longwall coal mining face, the width of the upper entry (2) and lower entry (8) of the deep shaft longwall coal mining face The thickness of the mining coal seam (1) is 3.0m; the prepared filling profile (6) is transported from the ground to the bottom of the well with a cage, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com