Patents

Literature

77results about How to "High degree of association" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

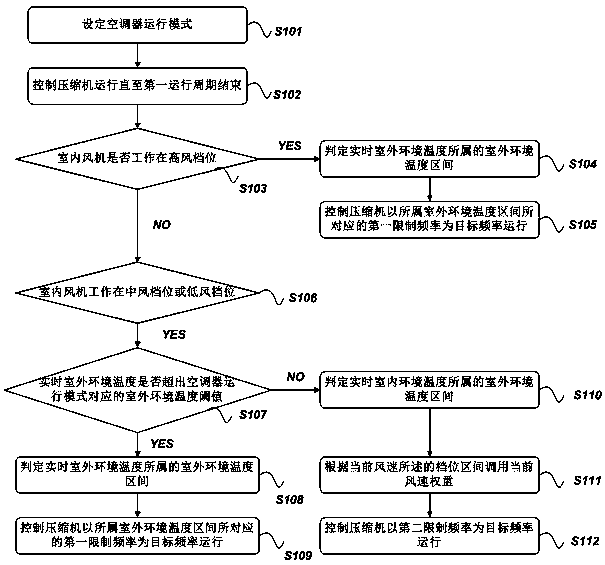

Air conditioner control method and air conditioner

ActiveCN109114729AHigh energy consumptionHigh degree of associationMechanical apparatusSpace heating and ventilation safety systemsEngineeringWind speed

The invention discloses an air conditioner control method. The air conditioner control method comprises the steps that a running mode is set; an air conditioner runs for a first running period and then is stopped; whether an indoor fan works at the high air gear or not is judged; if yes, the outdoor environment temperature interval is judged, and a compressor is controlled to run by taking first limiting frequency corresponding to the outdoor environment temperature interval as target frequency; if the indoor fan works at the middle air gear or the low air gear, whether the real-time outdoor environment temperature exceeds an outdoor environment temperature threshold value corresponding to the air conditioner running mode or not is judged; if yes, the outdoor environment temperature interval is judged, and the compressor is controlled to run at the first limiting frequency corresponding to the outdoor environment temperature interval; and if not, the outdoor environment temperature interval is judged, the current air speed weight is called, and the compressor is controlled to run by taking second limiting frequency as the target frequency. Meanwhile, the invention further disclosesan air conditioner. According to the air conditioner control method and the air conditioner, energy consumption of the compressor is intelligently optimized, and the balance among the human body comfort, the compressor energy consumption and the outdoor environment temperature is achieved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

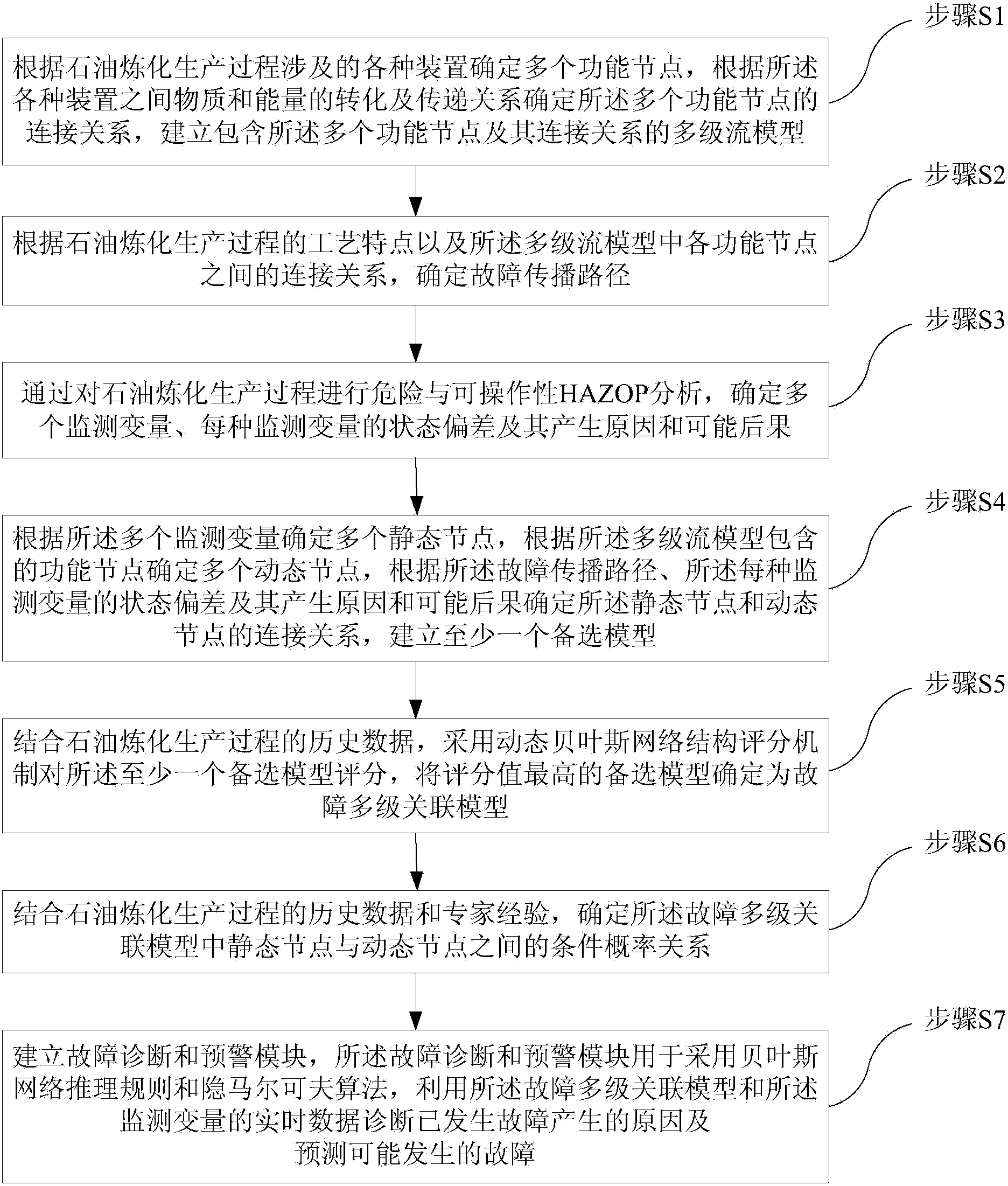

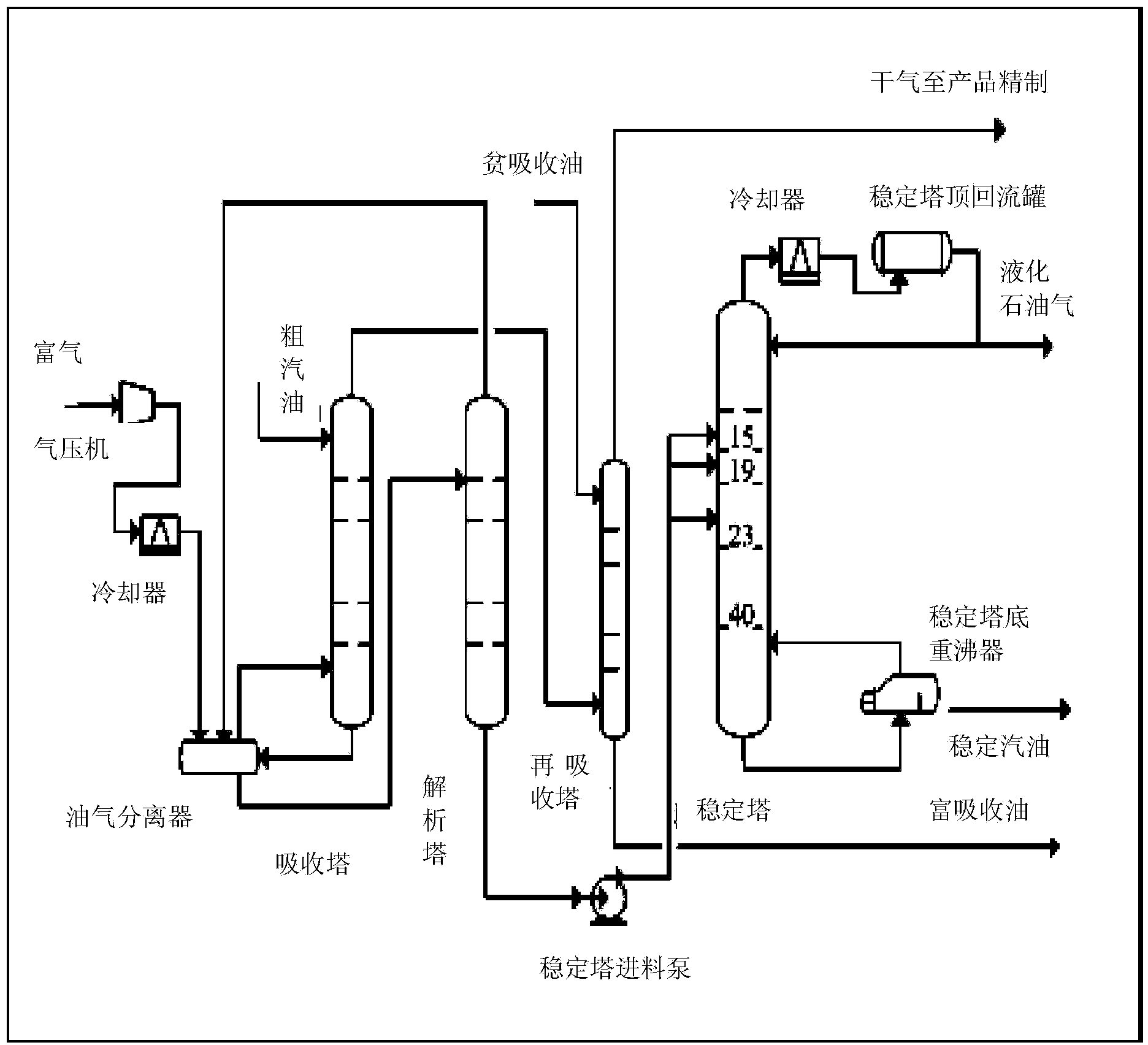

Fault diagnosis and pre-warning system in oil refining production process and establishment method thereof

ActiveCN104238545AStrong fault propagationStrong fault tracing and reasoning abilityElectric testing/monitoringOperabilityEngineering

The invention provides a fault diagnosis and pre-warning system in the oil refining production process and an establishment method of the fault diagnosis and pre-warning system. The method comprises the steps of establishing a multilevel flow model in the oil refining production process, determining a fault propagation path, conducting hazard and operability (HAZOP) analysis on the oil refining production process, determining a plurality of static nodes and a plurality of dynamic nodes, determining the connected relation of the static nodes and the dynamic nodes, establishing at least one alternative model, adopting the dynamic Bayesian network structure scoring mechanism for scoring of the alternative models, determining the alternative model with the highest score as a fault multilevel related model, determining the conditional probability relation between the static nodes and the dynamic nodes in the fault multilevel related model, and establishing a fault diagnosis and pre-warning module. The established fault multilevel related model and the fault diagnosis and pre-warning module have the higher fault propagation and fault tracing and reasoning capability, and accurate diagnosis and timely warning of faults generated in the oil refining production process can be achieved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

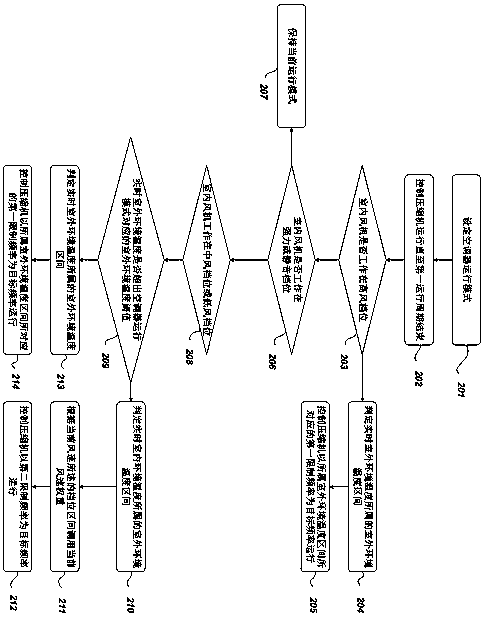

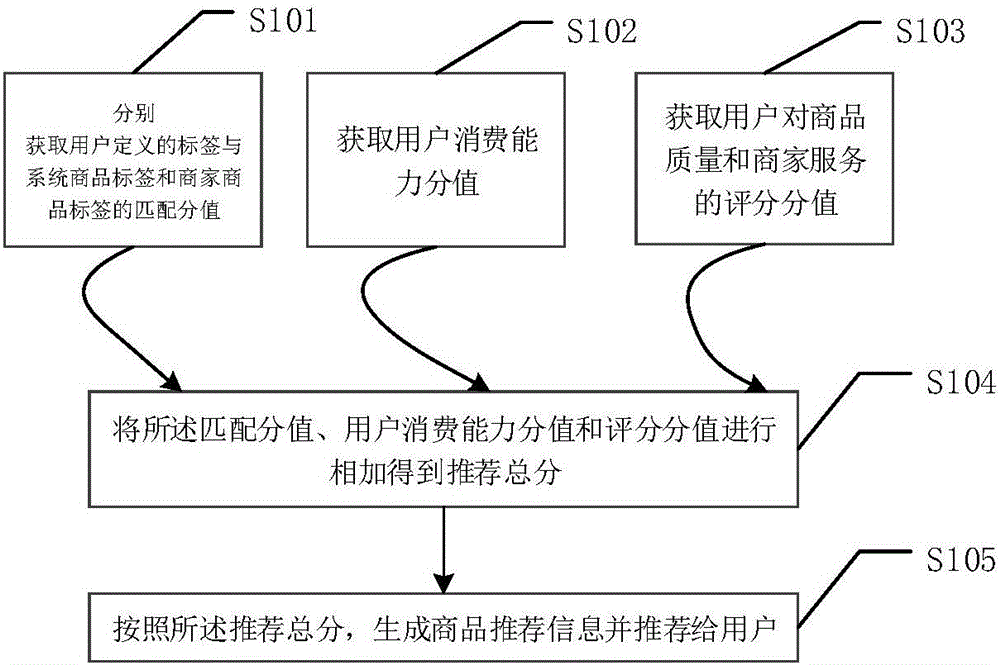

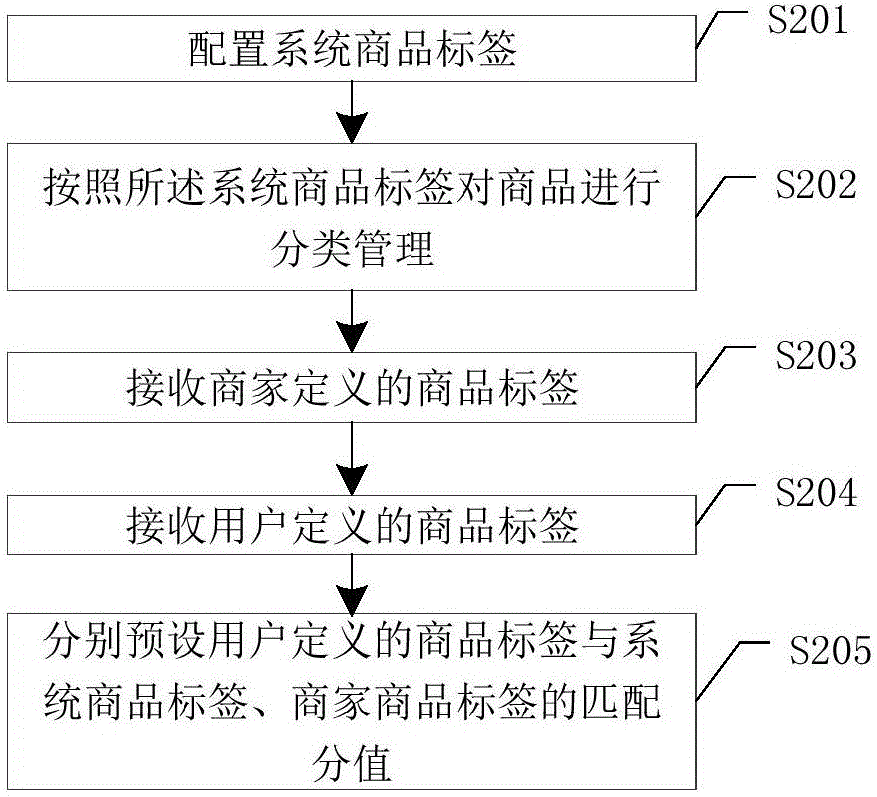

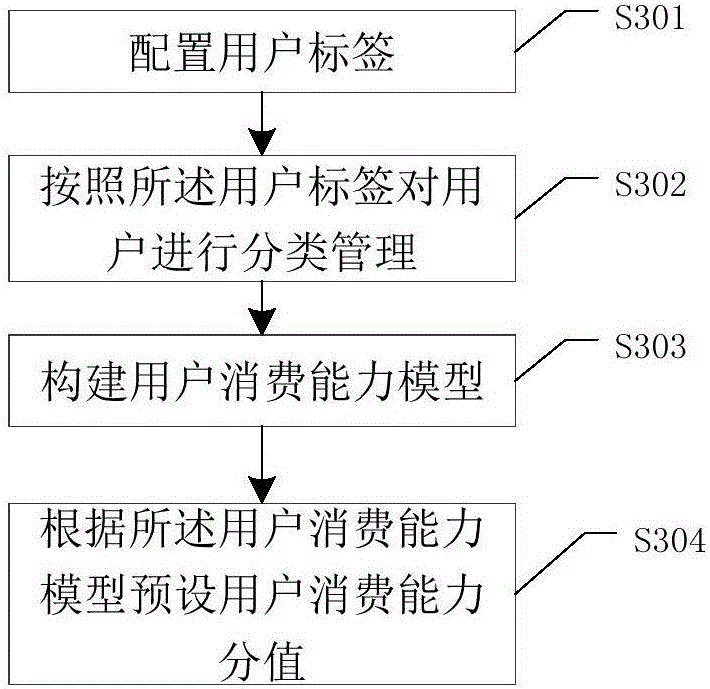

Shopping recommended method and system

InactiveCN106408377AHigh degree of associationBuying/selling/leasing transactionsMerchant servicesDegree of association

The invention belongs to the network technical field and provides a shopping recommendation method and system. The shopping recommendation method includes the following steps that: the matching score of a label defined by a user, a system commodity label and a merchant commodity label is obtained; the consumption ability score of the user is obtained; the rating score of commodity quality and merchant service, which is provided by the user, is obtained; the matching score, the consumption ability score and the grading score are added together, so that a total recommendation score can be obtained; and commodity recommendation information is generated and is recommended to the user according to the total recommendation score. According to the shopping recommendation method and system of the invention, the total recommendation score is determined by analyzing user information, commodity information and rating information, and comprehensive consideration of multi-faceted information makes the degree of association between a recommended commodity and the user improved.

Owner:广东华邦云计算股份有限公司

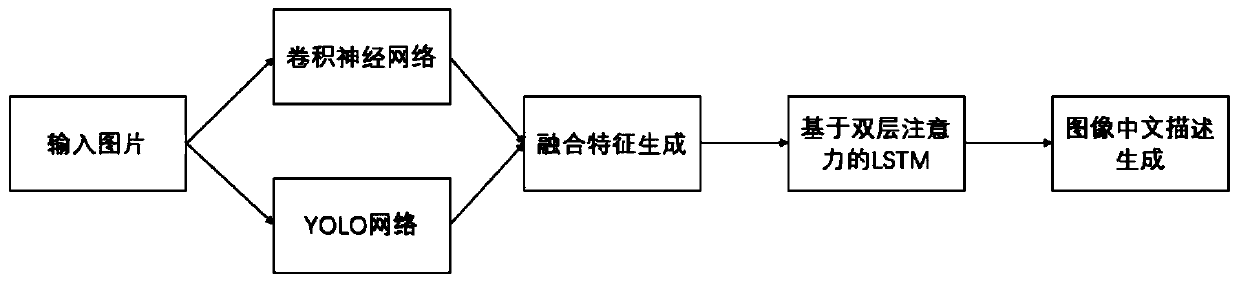

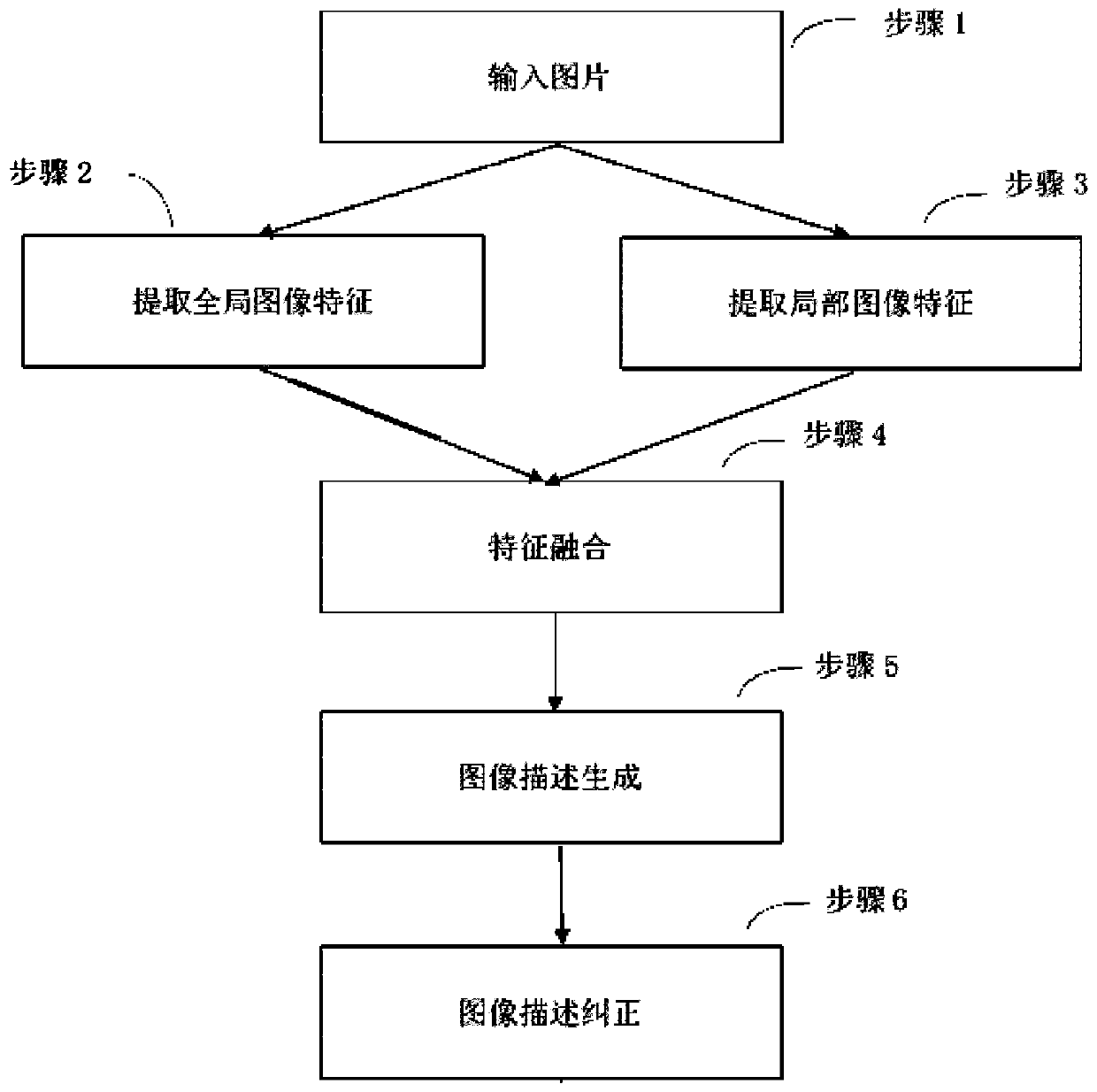

Power transmission and transformation scene description automatic generation method fusing global information and local information

ActiveCN111325323AHigh degree of associationEnriching Information in Visual SemanticsCharacter and pattern recognitionNeural architecturesPattern recognitionVisual technology

The invention discloses a power transmission and transformation scene description automatic generation method fusing global information and local information, and aims to perform image Chinese description generation on a power transmission and transformation scene: extracting local and global feature information of an image by combining deep learning and a traditional computer vision technology; the semantic information of each Chinese segmented word is associated with the fused feature information; a long-term and short-term memory neural network is improved, a double-layer attention mechanism is added, an established sequence model generates distribution of an attention variable at each moment according to image feature information and semantic information, and finally Chinese description corresponding to an image is generated.

Owner:SHANDONG UNIV +3

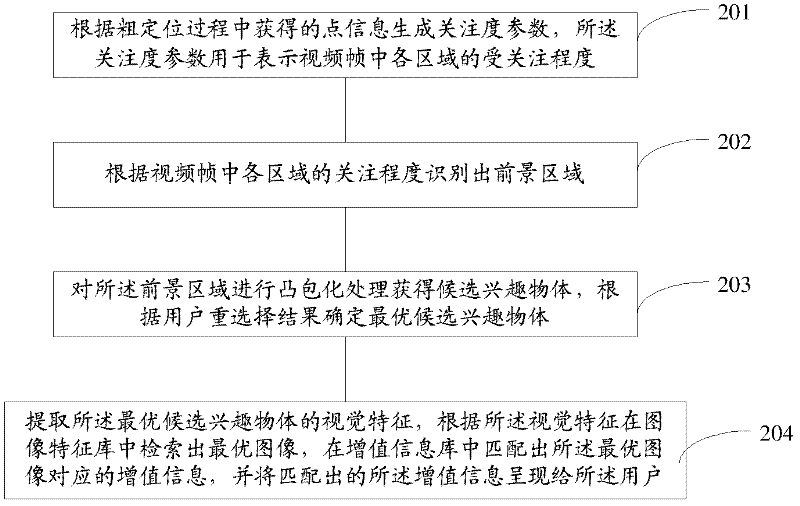

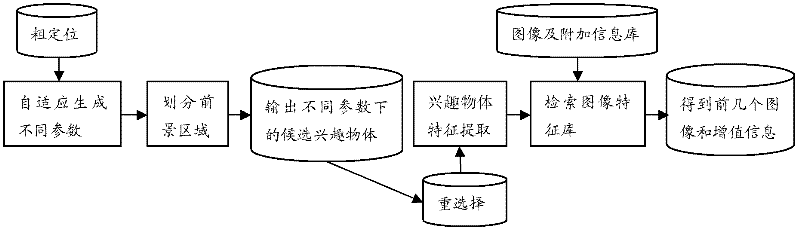

Method and system for extracting and correlating video interested objects

ActiveCN102232220AEasy to understandEasy to exploreImage analysisMetadata video data retrievalInformation repositoryObject based

The present invention relates to an image and video processing method, especially to a method for extracting and correlating video interested objects based on a two-stage interaction. In the method, a user performs an approximately positioning interaction by using a kind of interaction method which is not limited to a general mode and with a low requirement for priori knowledges, and then performs multiparameter extraction on the interested objects by using a quick and realizable extraction algorithm. Based on the most suitable interested object obtained by the reselection and interaction, the present invention performs searching and weighting by extracting various characteristics to obtain a final result, picks out corresponding images and additional information from a value-added information base, and shows the information at peripheral of the video. The method correlates the value-added information to the interested object of the user without influencing watching of the user by fully mining video information and ensuring preference of the user, thereby satisfying the requirment of the user that the area of interest needs to be looked into and further explored.

Owner:HUAWEI CLOUD COMPUTING TECH CO LTD

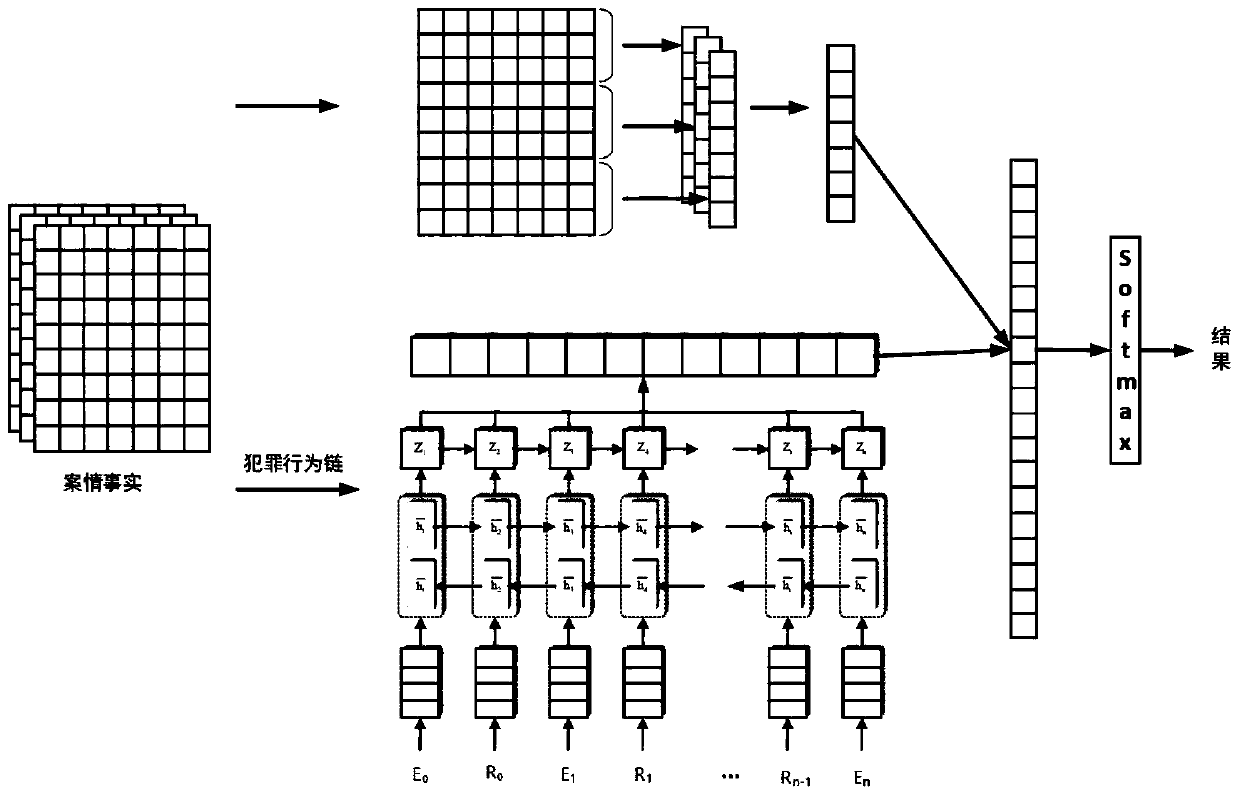

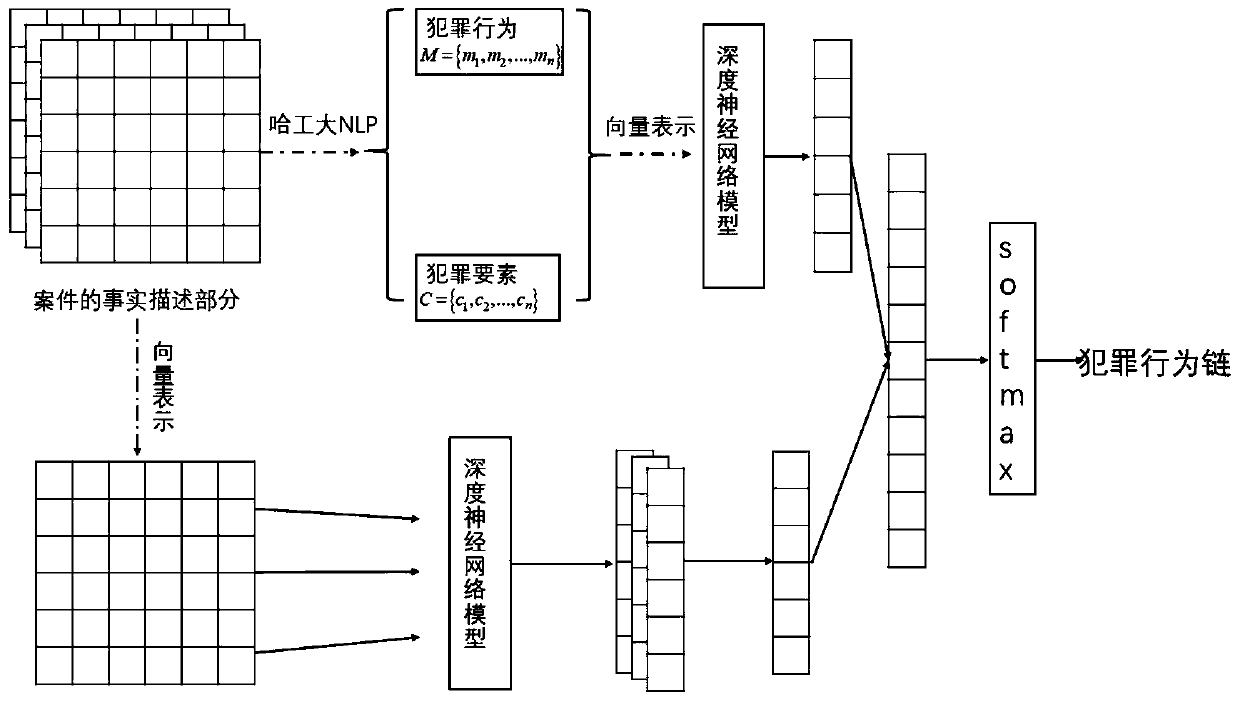

Judgment document analysis method based on criminal behavior chain

InactiveCN110457479ARaise the importanceAlleviate the sparsity problemNeural architecturesSpecial data processing applicationsDocument analysisText categorization

The invention discloses a judgment document analysis method based on a criminal behavior chain, and the method comprises the following steps: step 1, extracting information from the fact description of a case, declaring the concept and construction rule of the criminal behavior chain, and constructing the criminal behavior chain; step 2, obtaining semantic information from fact description of a case by using a TextCNN; step 3, based on the criminal behavior chain, performing vector representation on the criminal behavior chain by using a Bi-LSTM method, and performing text classification; andstep 4, proposing a judgment document analysis method of a neural network structure for splicing and outputting a result of the TextCNN method and a result of the Bi-LSTM method, wherein an identification result can be used for supporting various auxiliary judgment applications. According to the method disclosed by the invention, the associated information of the criminal behavior chain is fully utilized, the defects of a traditional legal judgment document analysis method are avoided, the judgment document analysis efficiency is improved, and a technical support is provided for solving modelsand methods for assisting judgment such as legal provision recommendation and class case pushing.

Owner:GUIZHOU UNIV +2

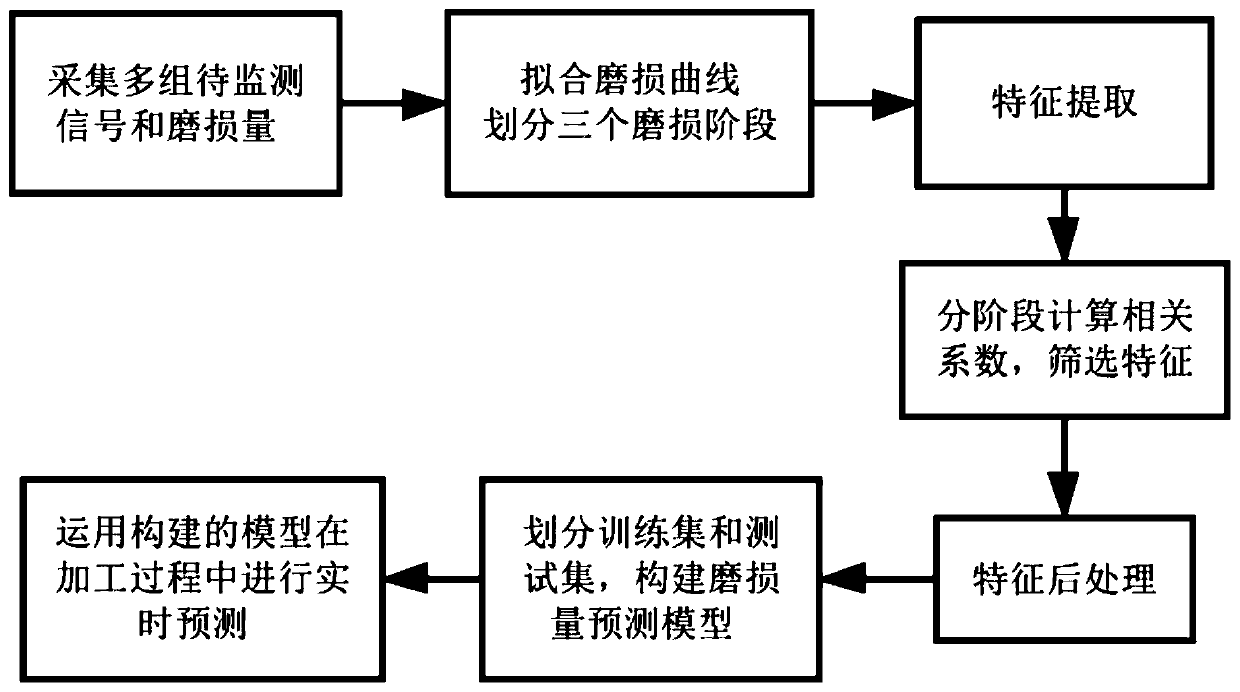

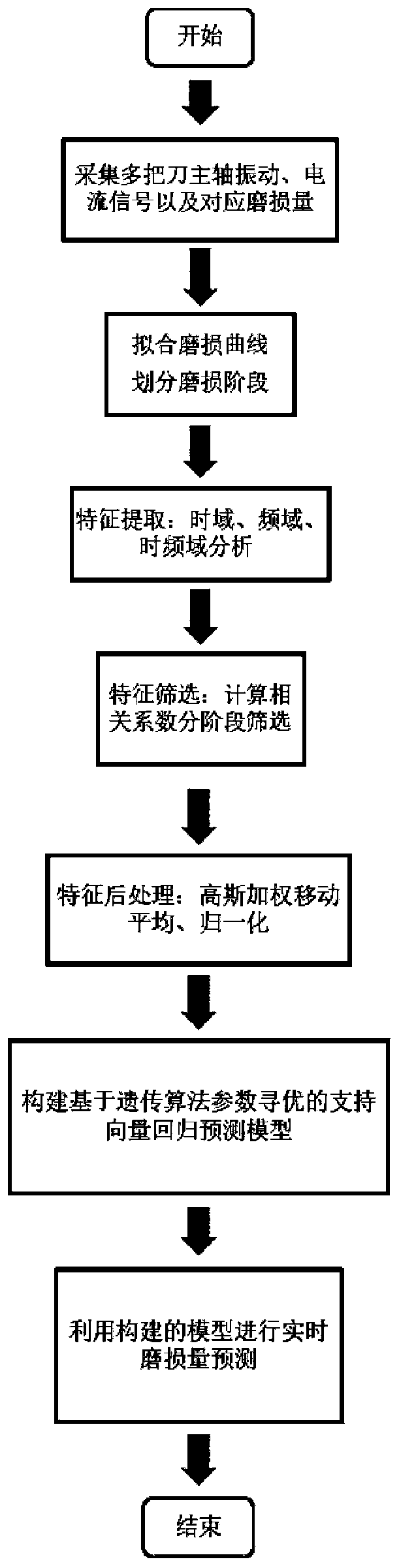

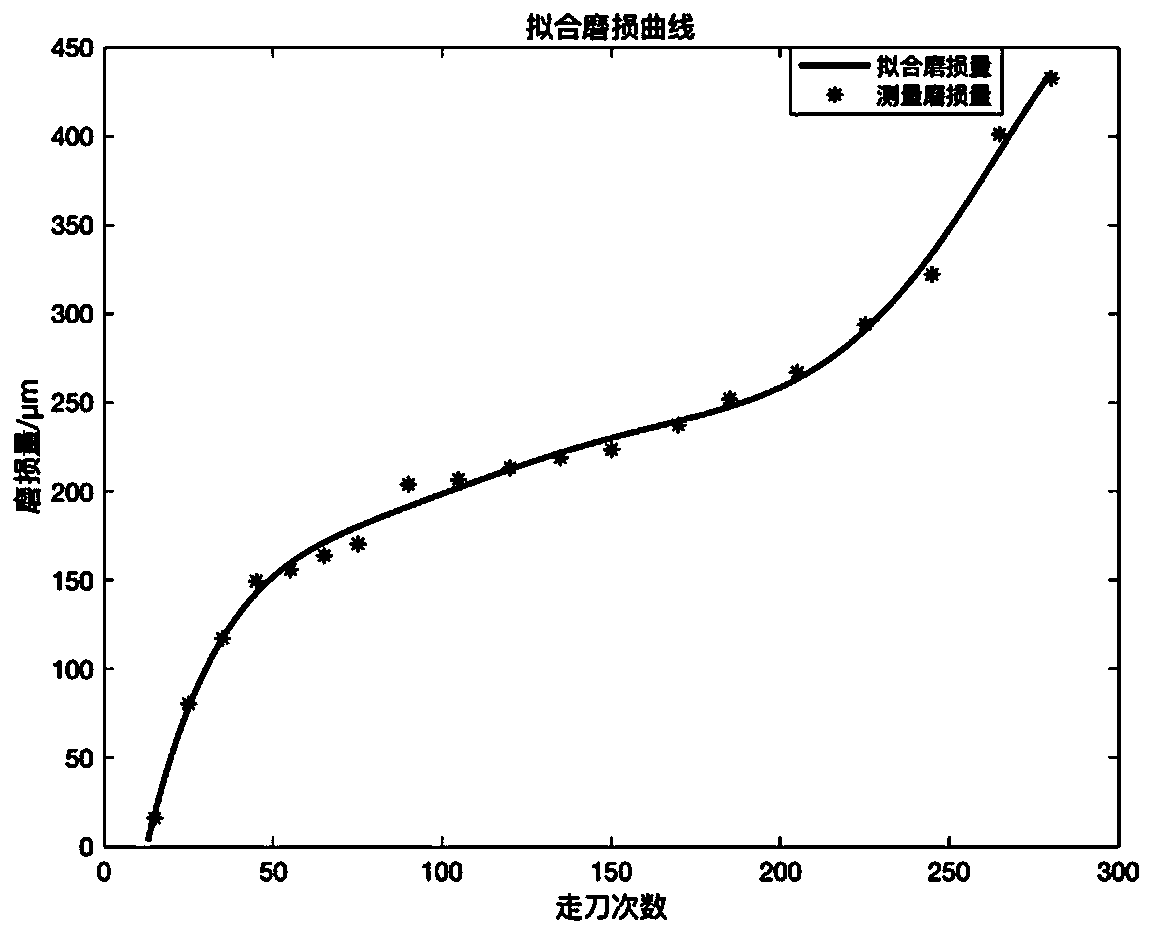

Numerical control machine tool cutter wear loss online prediction method based on spindle currents and vibration signals

ActiveCN111300146AHigh degree of associationImprove forecast accuracyMeasurement/indication equipmentsMachine learningReal time prediction

The invention discloses a numerical control machine tool cutter wear loss online prediction method based on spindle currents and vibration signals. The method is characterized in that multiple cuttersof the same model are utilized to repeatedly carry out trial operation machining under the same working condition on a numerical control machine tool spindle provided with a sensor, and original machining wear data are measured; according to three wear stages of the initial rapid wear stage, the normal wear stage and the rapid wear stage of the cutters, an optimal feature set for training is extracted from each wear stage, and a support vector regression machine prediction model is trained; and finally the trained model is adopted for online real-time prediction of cutter wear loss in the actual machining process. According to the method, through the data obtained by repeated experiments through the multiple of cutters of the same model under the same condition, characteristic parameters,related to cutter wear, in the wear stages in original signals can be fully mined, the relational degree between the characteristics and the cutter wear loss is enhanced through a post-processing mode, and therefore, the constructed support vector regression machine prediction model can obtain high prediction precision and good generalization performance.

Owner:SHANGHAI JIAO TONG UNIV

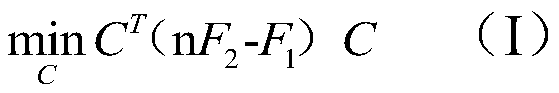

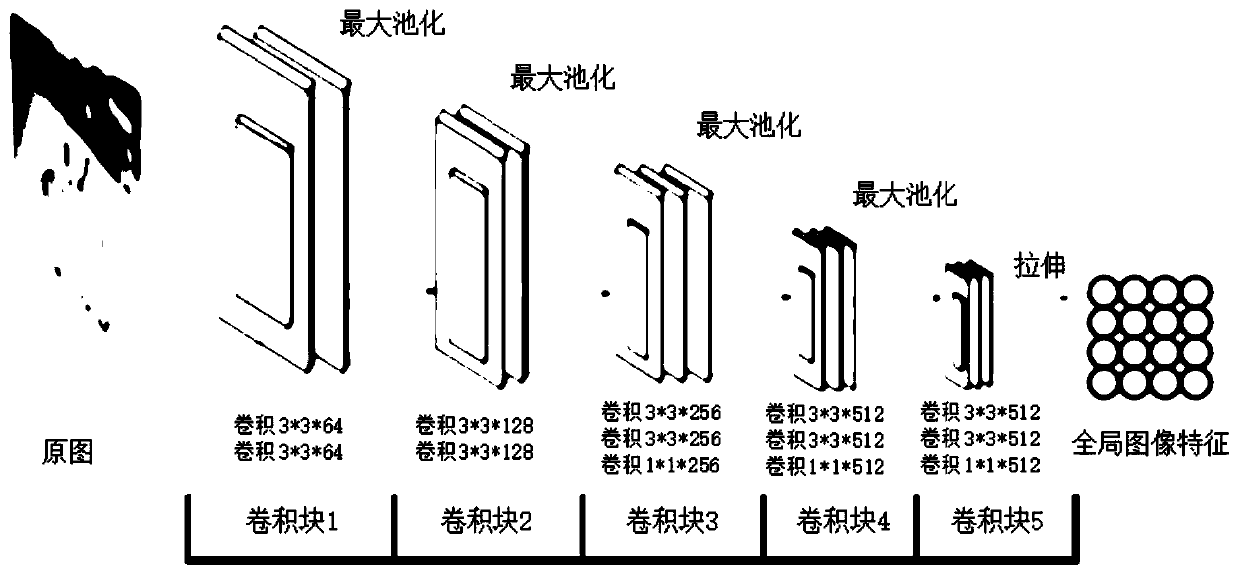

Image description method

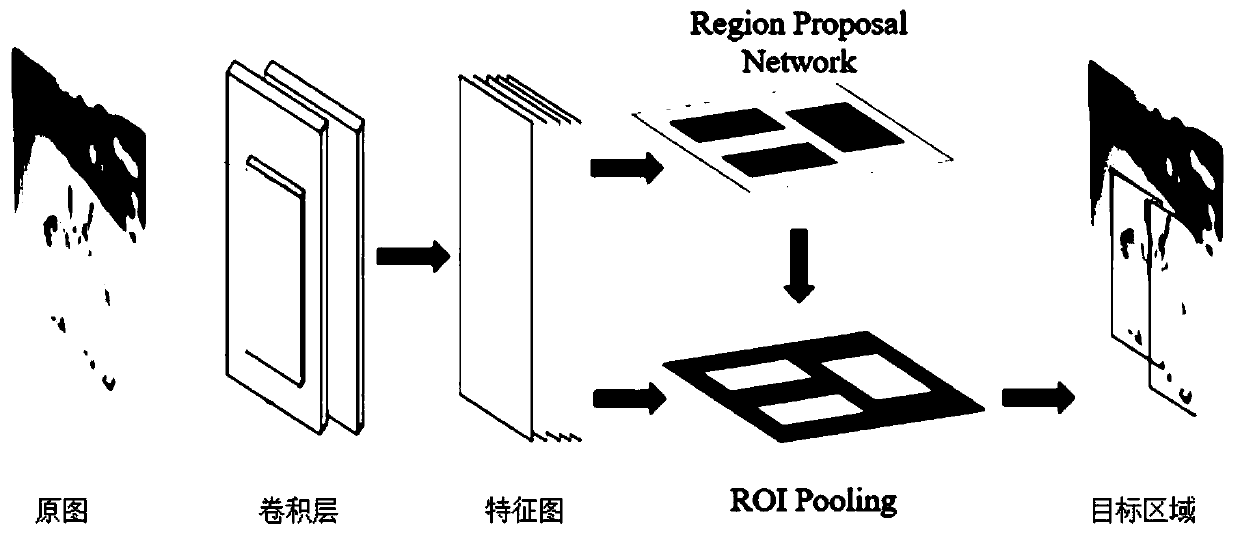

InactiveCN110390363AReduce the impactImprove performanceCharacter and pattern recognitionNatural language data processingFault toleranceImage description

The invention discloses an image description method, and the method comprises the steps: extracting global image features in a picture through a VGG convolution neural network, and extracting local image features in picture by using Faster R-CNN network, fusing global image features and local image features through a global-local feature fusion algorithm to acquire the image fusion features; processing image fusion features through a bidirectional long-short-term memory network with an attention mechanism; and generating a preliminary image description statement, performing WordNet word vectorsimilarity calculation based on the image target information obtained during local image feature extraction and nouns in the preliminary image description statement, correcting the image descriptionstatement, and generating a final image description statement. According to the method, the influence of useless information is reduced, the expression of key information is enhanced, the fault tolerance and generalization ability of the model are enhanced, and the accuracy of statement description is improved.

Owner:SHANGHAI MARITIME UNIVERSITY

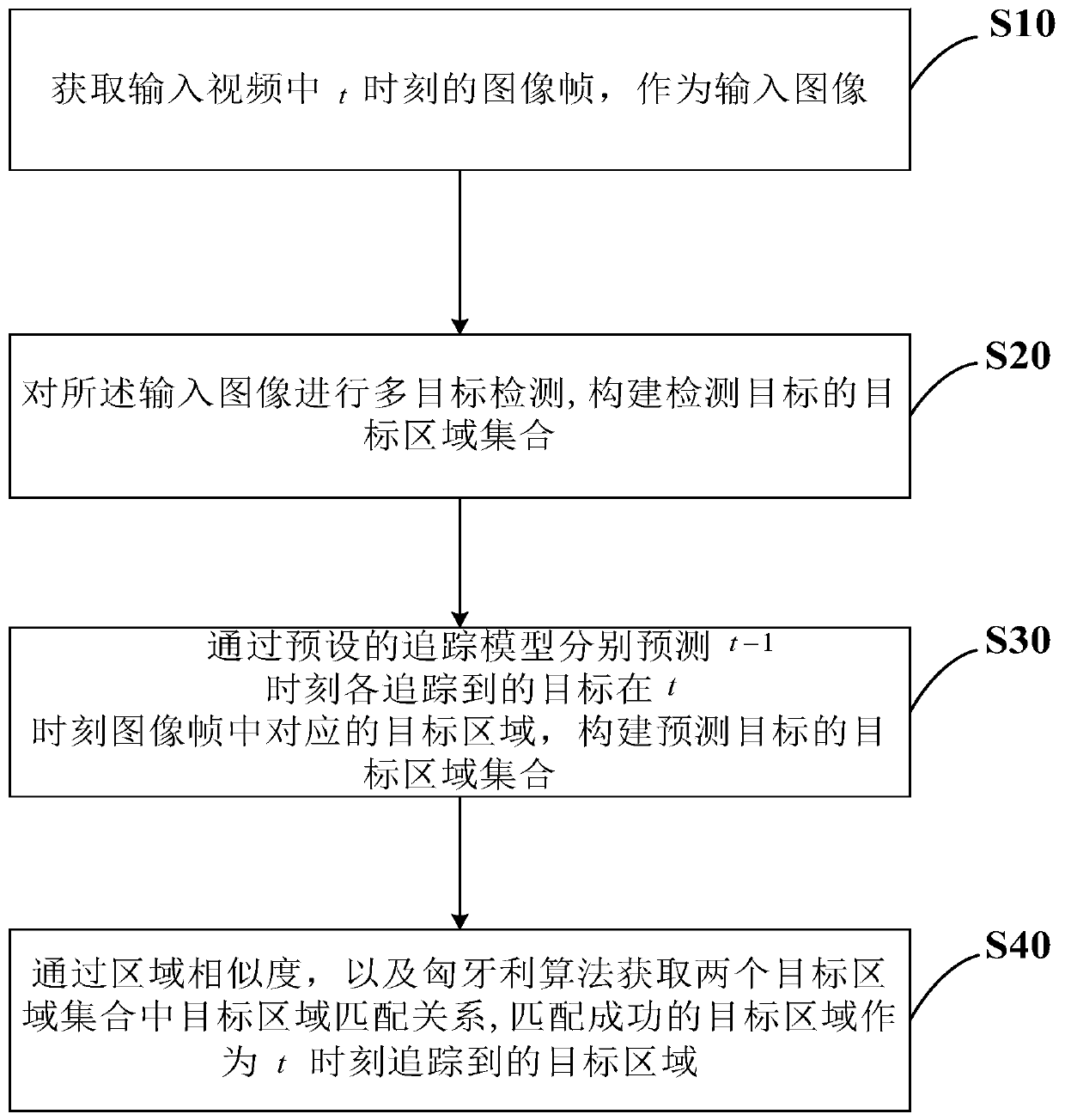

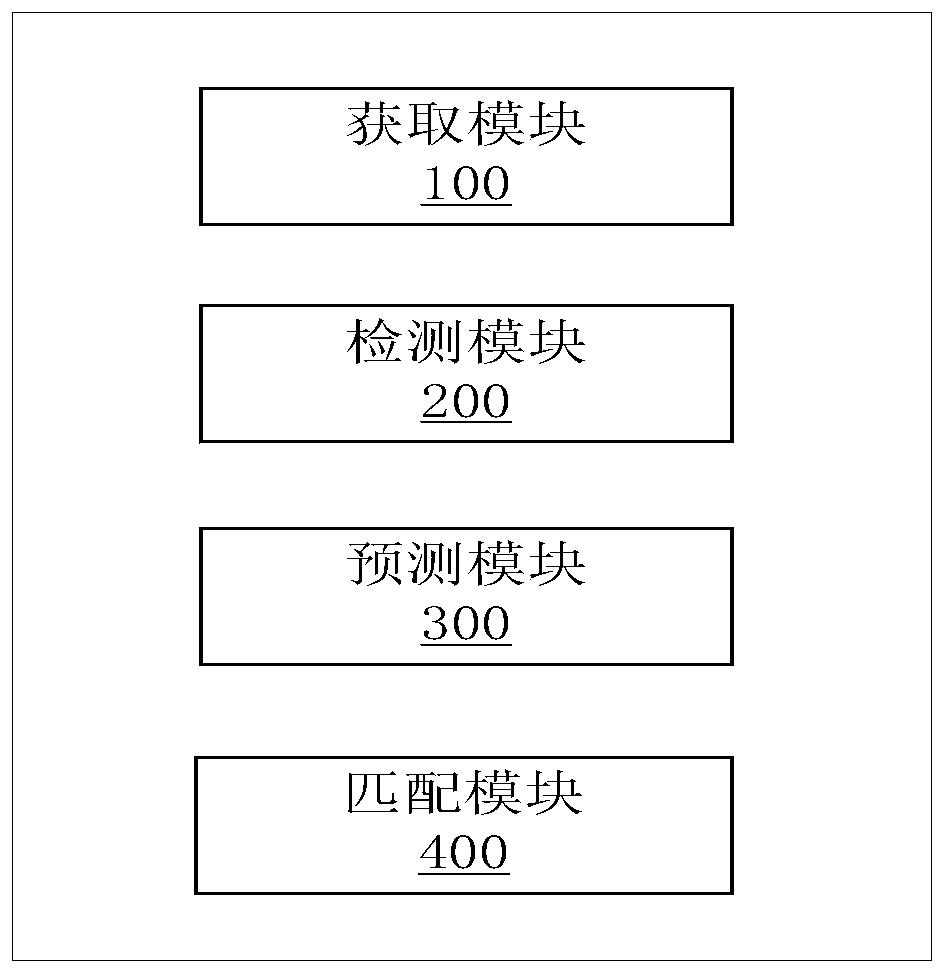

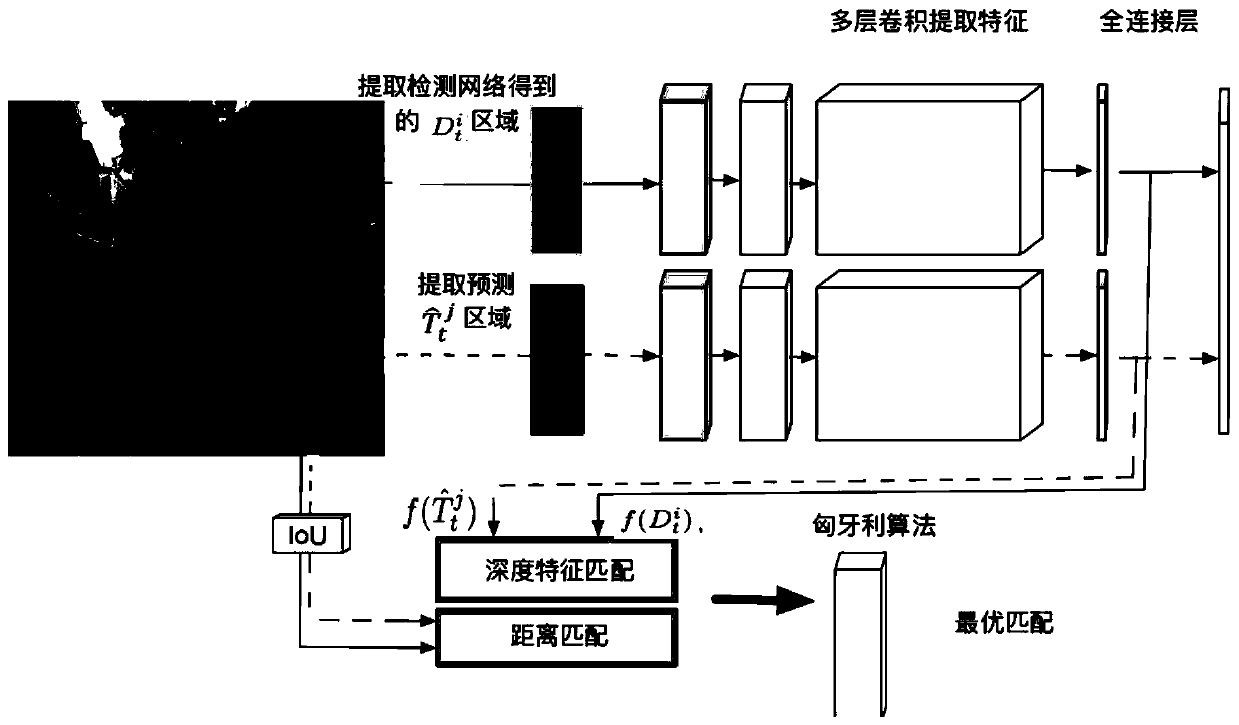

Multi-target tracking method, system and device based on optical flow and Kalman filtering

ActiveCN110415277AHigh degree of associationImprove accuracyImage enhancementImage analysisTracking modelMulti target tracking

The invention belongs to the field of intelligent driving, particularly relates to a multi-target tracking method, system and device based on optical flow and Kalman filtering, and aims to solve the problem that multi-target tracking excessively depends on detection and is high in matching difficulty. The method of the system comprises the following steps: acquiring an image frame at t moment in an input video; performing multi-target detection on the image frame, and constructing a target region set of detection targets; according to the target tracked at time t-1, predicting the corresponding target area of the target in the image frame at time t by the preset tracking model, and constructing the target area set of the predicted target; for the target area sets of the detection target and the prediction target, obtaining a target area matching relationship in the two target area sets through area similarity and a Hungary algorithm; and taking the successfully matched target area in the target area set of the detection target as the target area tracked at the t moment. According to the invention, accurate prediction of multiple targets is realized, and the accuracy of position matching and tracking of multiple frames of targets is improved.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

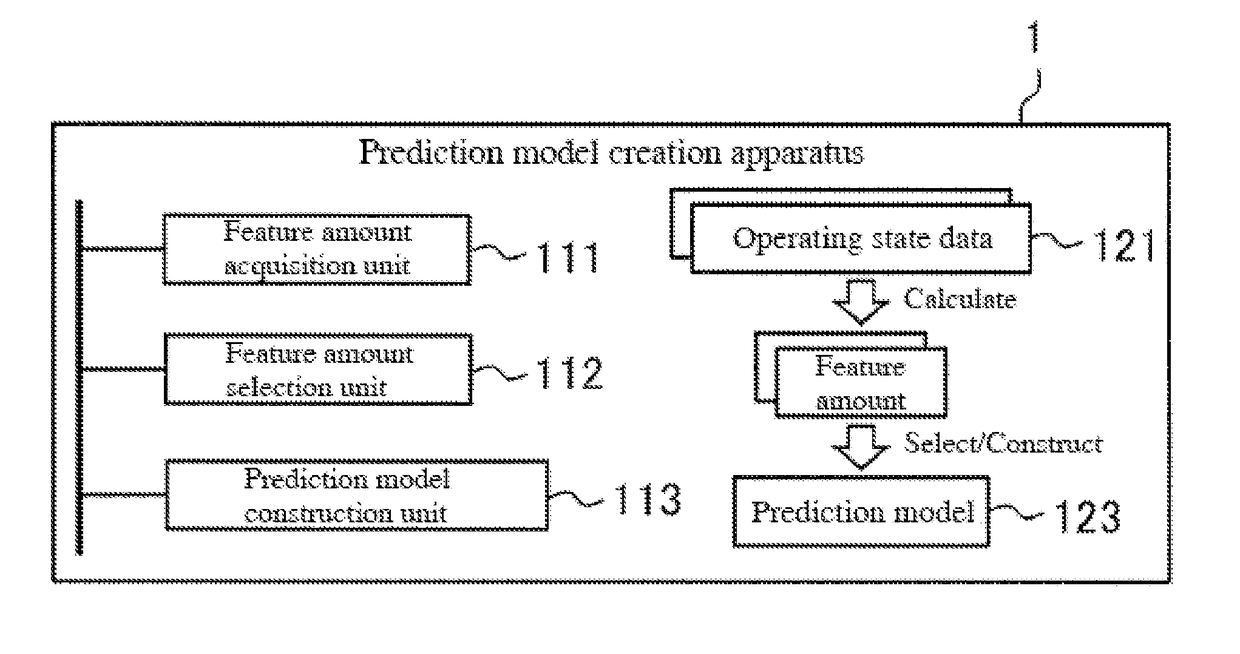

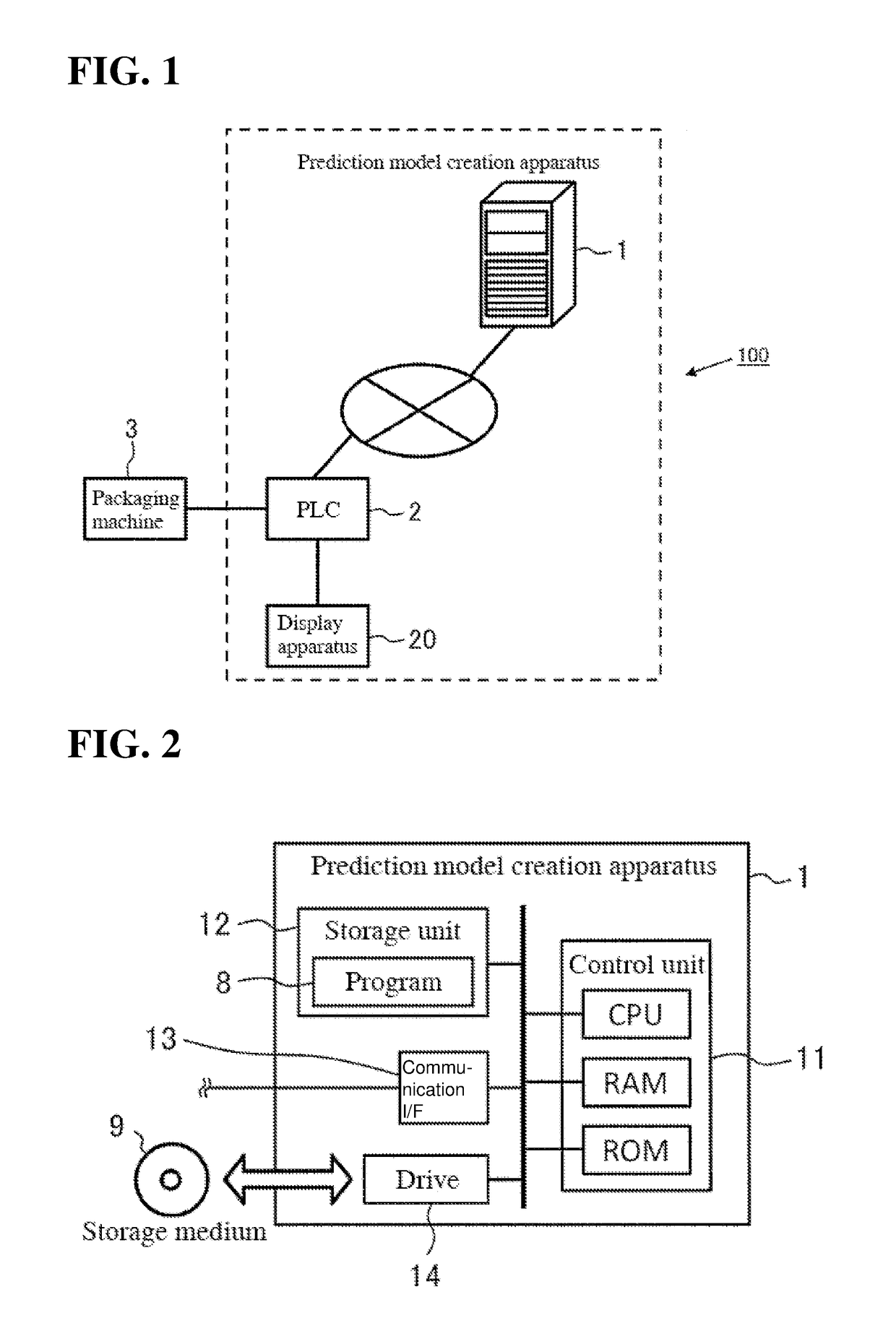

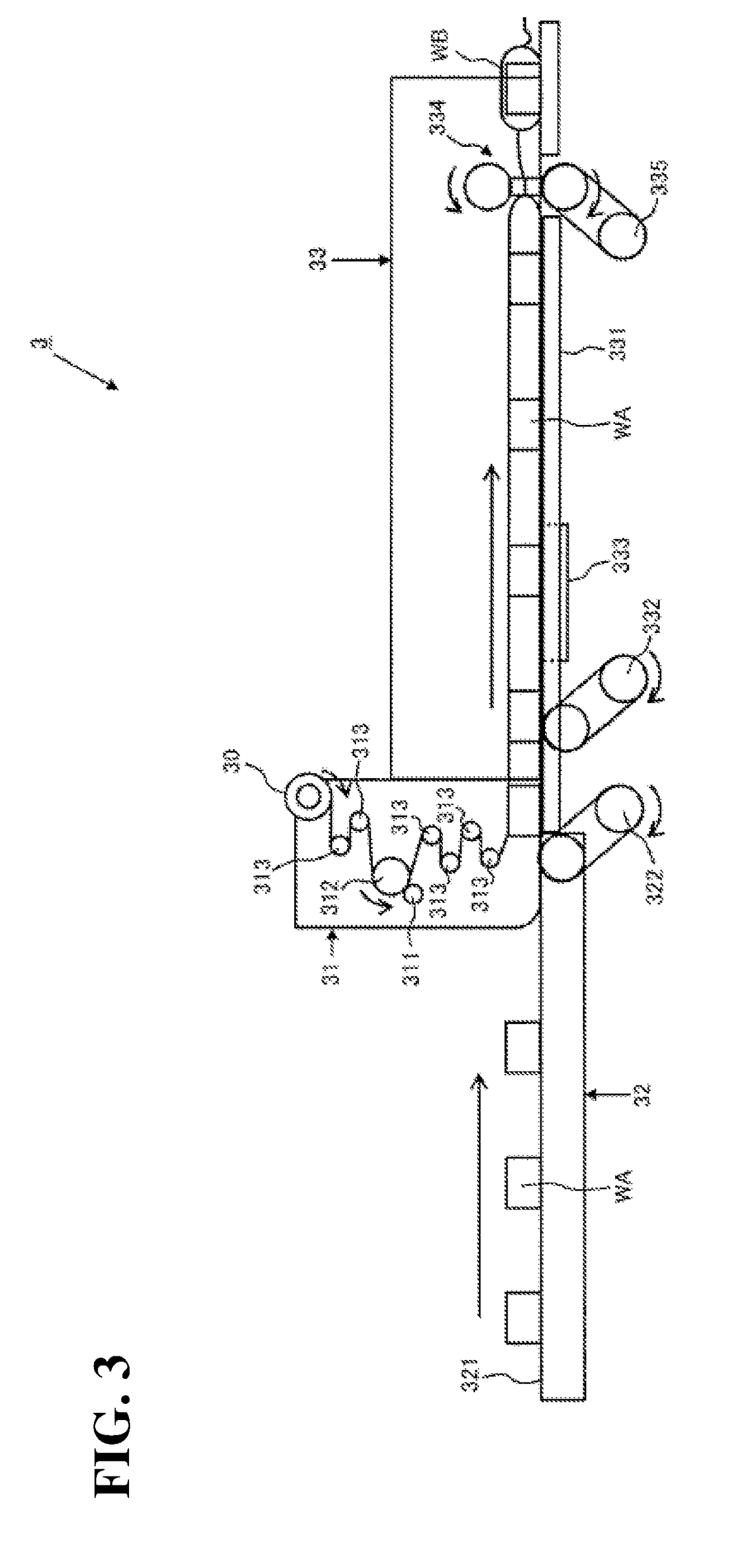

Prediction model creation apparatus, production facility monitoring system, and production facility monitoring method

ActiveUS20180203439A1Effective predictionHigh degree of associationElectric testing/monitoringBiological neural network modelsMonitoring systemEngineering

A prediction model creation apparatus includes a feature amount acquisition unit that acquires values of types of feature amounts that are calculated from operating state data indicating an operating state of a production facility that produces a product, for both a normal time at which the production facility produces the product normally and a defective time at which a defect occurs in the product that is produced, a feature amount selection unit that selects a feature amount effective in predicting the defect from among the acquired types of feature amounts, based on a predetermined algorithm that specifies a degree of association between the defect and the types of feature amounts, from the values of the types of feature amounts acquired at the normal time and the defective time, and a prediction model construction unit that constructs a prediction model for predicting occurrence of the defect, using the selected feature amount.

Owner:ORMON CORP

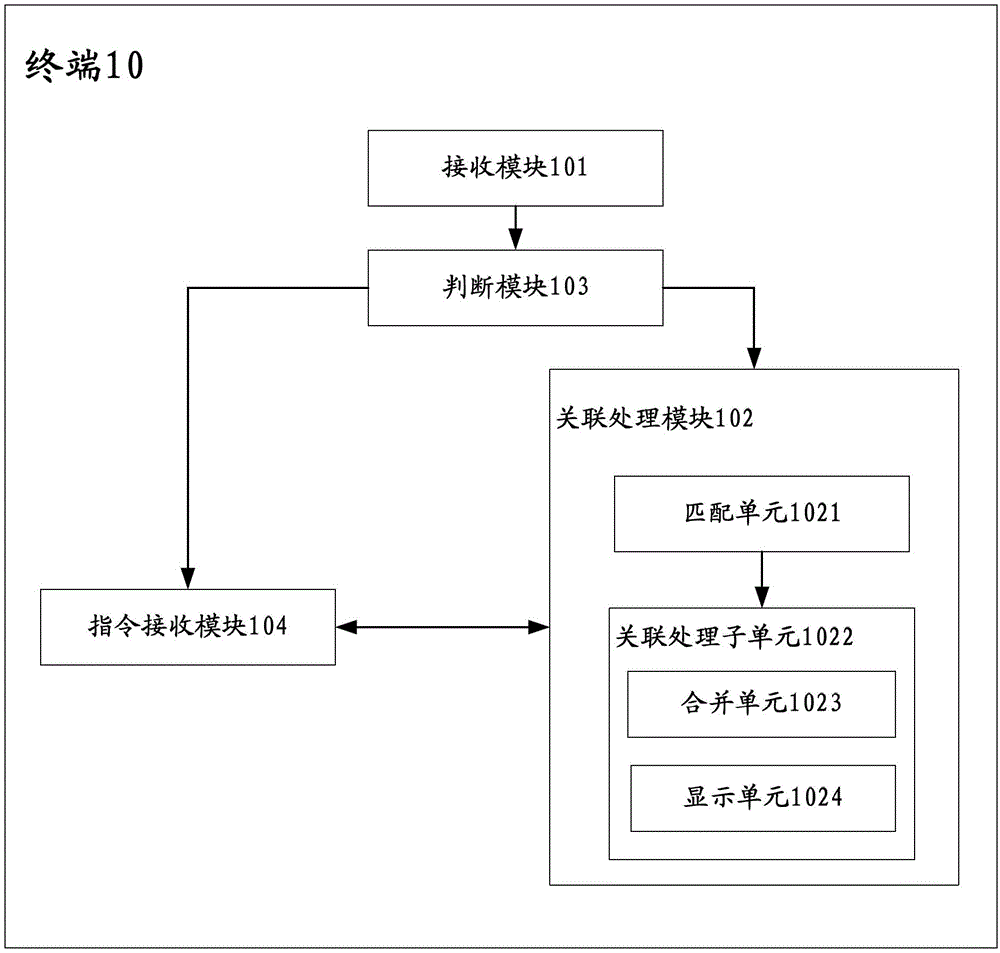

Mail processing method and terminal

InactiveCN103338147AAvoid the cumbersome process of operating aloneImprove operational efficiencyData switching networksEmail attachmentAssociative processing

The invention discloses a mail processing method and terminal. By associatively processing attached documents in one or more received electronic mails, the complicated process of operating the attached documents in the mails in sequence or independently is avoided, the operation steps are effectively reduced, the operation efficiency of a user is improved, and the user is enabled to obtain good operation experience. Meanwhile, according to the application, different electronic mails can be matched according to at least one of mail content, mail subjects, sender information and attached document names in the mails, for example, the mails are matched according to names of sub-volume compressed files, so that the association degrees of the attached documents of the matched electronic mails are higher and the associative processing accuracy of the attached documents is improved.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

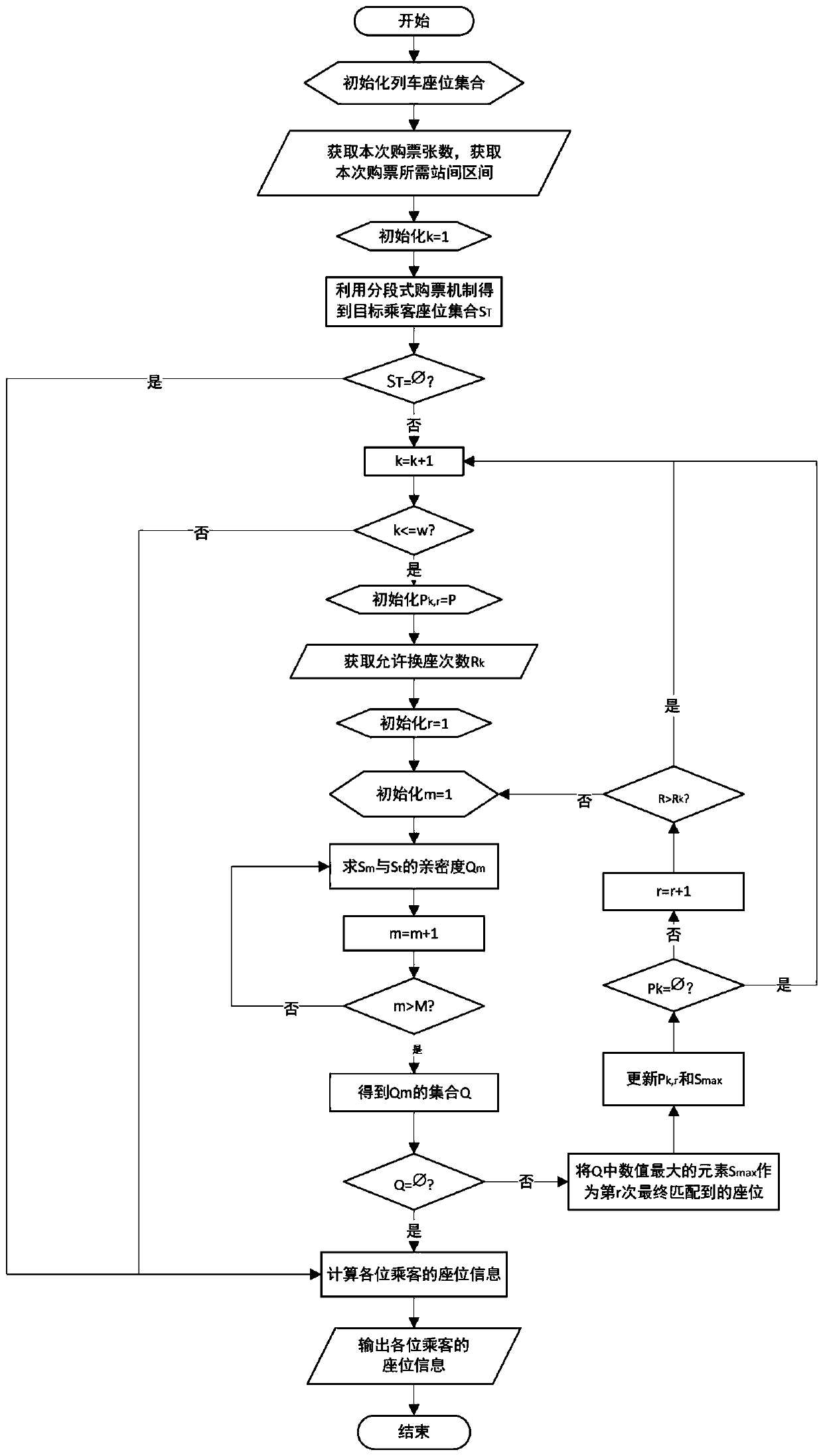

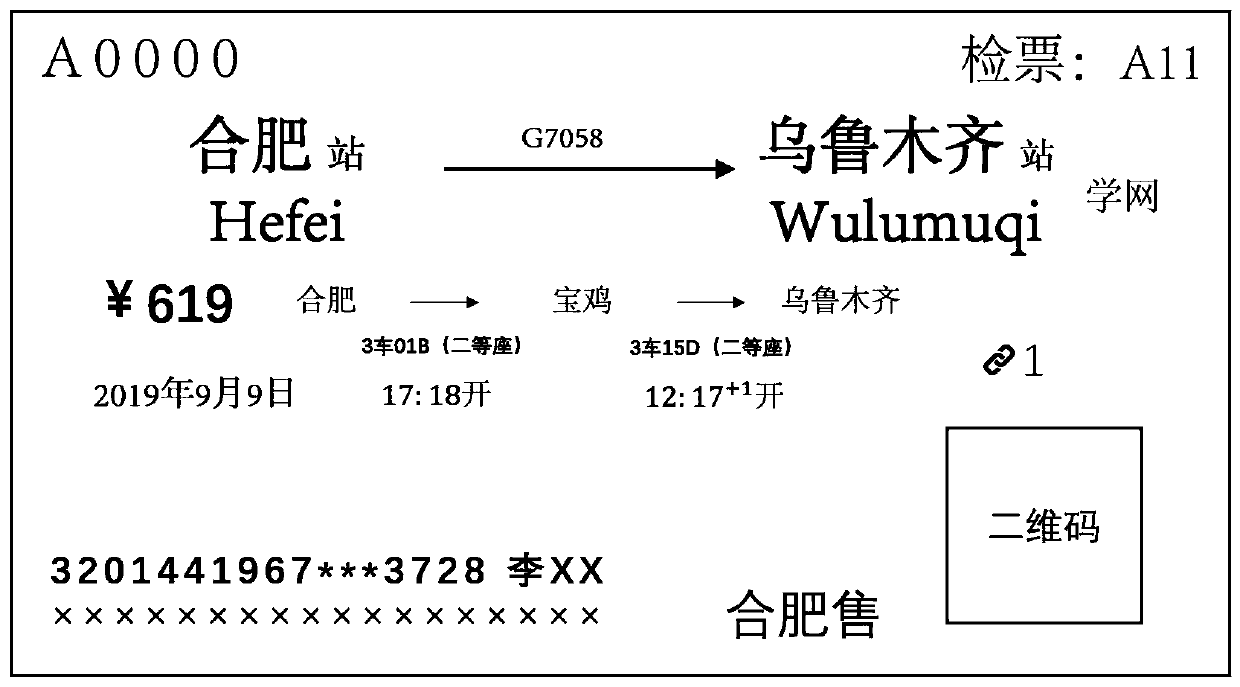

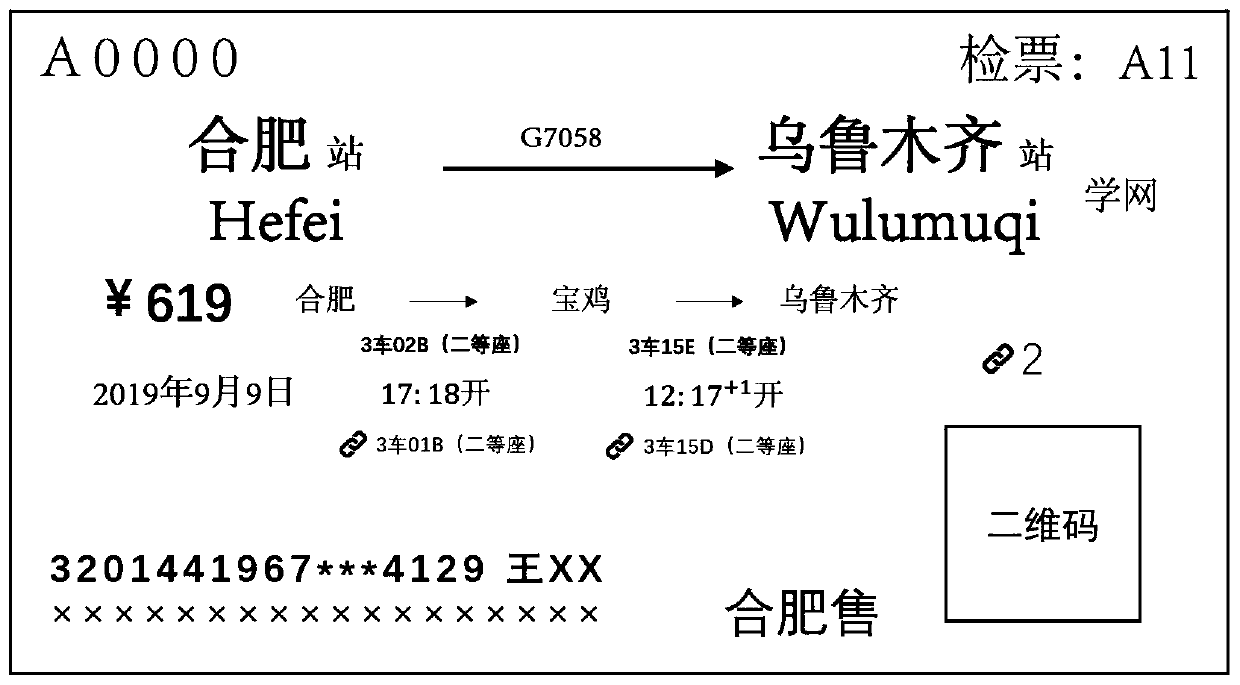

Segmented seat-associated ticket-selling method for train

ActiveCN110648407ASolve the disadvantages of the random allocation ticket sales modelEfficient and reasonable useMachines for printing and issuing ticketsTicketSeating capacity

The invention discloses a segmented seat-associated ticket-selling method for a train. The ticket-selling method comprises steps: 1, establishing a database about total numbers of seats in a train; 2initializing seat information in the train and information of a plurality of passengers participating in ticket purchase in which a first passenger who buys a ticket is set as a target passenger and remaining passengers are set as related passengers; 3, acquiring ticket-buying information of the target passenger and the related passengers in the related ticket purchase, including numbers of passengers, boarding interval, and number of seat changes allowed; 4, matching the target passenger to the most suitable seat in the seat database and updating the seat information; 5, matching the relatedpassengers to the seat most close to the target passenger in the seat database and updating the seat information; 6, outputting ticket information of each passenger. The segmented seat-associated ticket-selling method for the train can further improve segmented ticket-buying mode to obtain a plurality of tickets with seats as close to each other as possible for a long time, providing more convenience for passengers traveling with a group or buying tickets in a group, and making the ticket-selling system more user-friendly.

Owner:HEFEI UNIV OF TECH

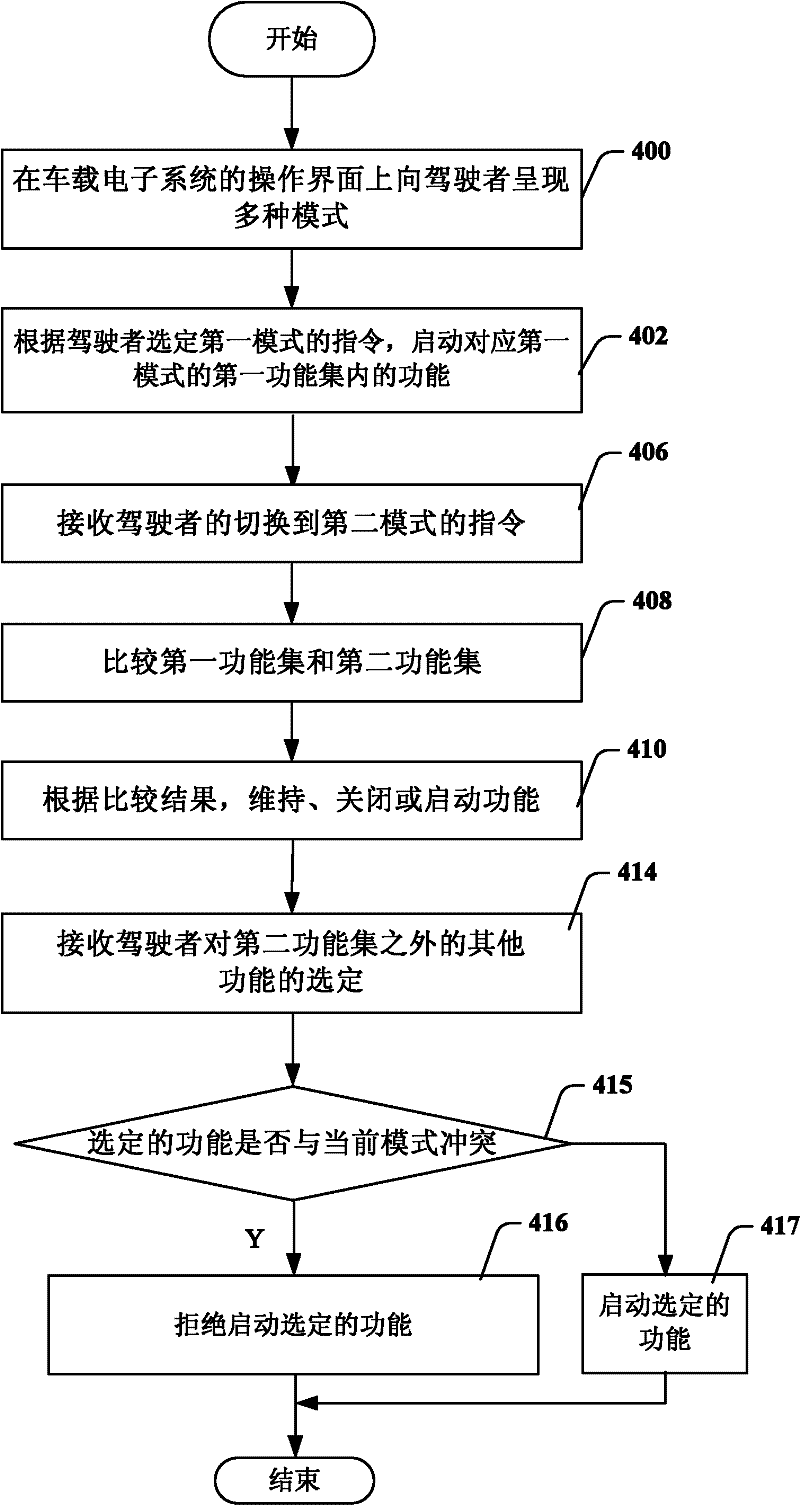

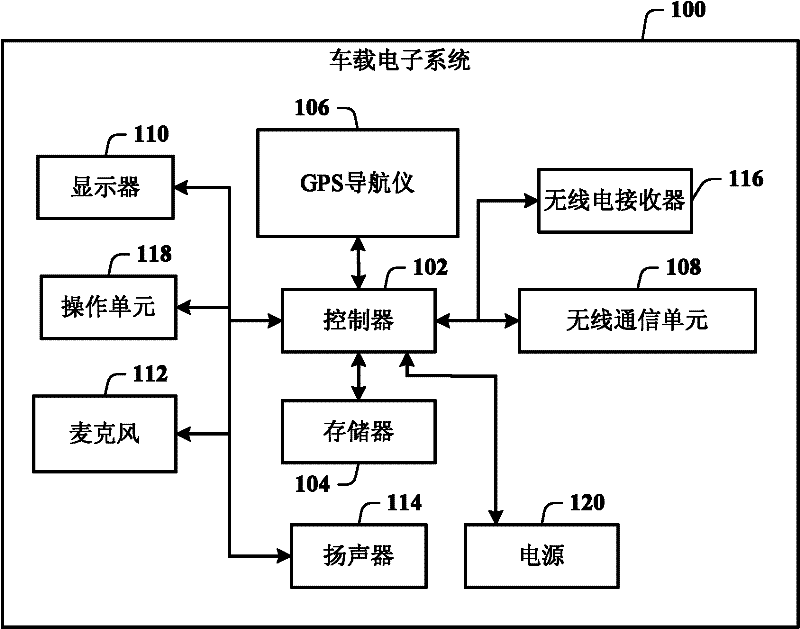

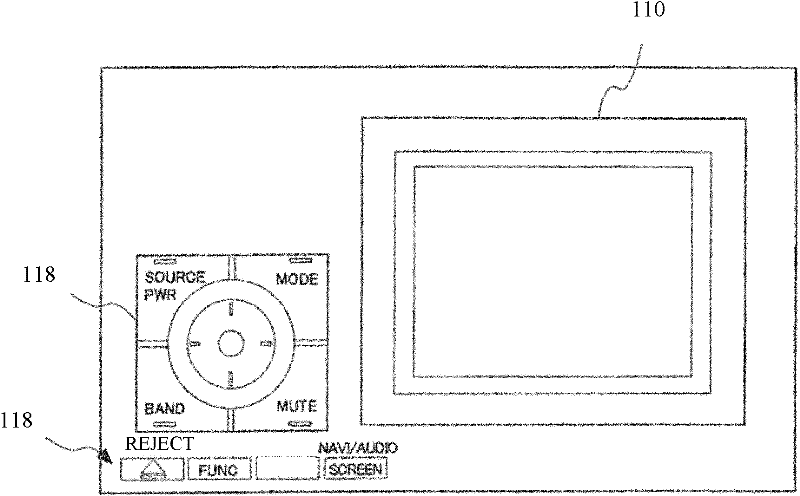

Mode switching method for vehicle-mounted electronic system

ActiveCN102541415AHigh degree of associationStrong importanceInput/output processes for data processingElectronic systemsMode switch

The invention discloses a mode switching method for a vehicle-mounted electronic system, which allows a driver to switch modes each of which has one or more functions according to a particular driving scene. The method comprises: showing the driver a plurality of modes on the operation interface of the vehicle-mounted electronic system, wherein each mode corresponds to a function set, and each function set comprises functions selected from a group of auxiliary driving functions and / or a group of non-auxiliary driving functions; starting the functions in a first functional set corresponding to a first mode according to the instructions of the first mode selected by the driver, and entering the first mode; receiving the instruction sent by the driver for switching to a second mode; comparing a second function set corresponding to the second mode with the first function set; and according to the result of the comparison, keeping the common functions of the first function set and the second function set, temporarily stopping, closing or suspending the functions only included in the first function set, starting the functions only included in the second function set, and thus entering the second mode.

Owner:SHANGHAI PATEO ELECTRONIC EQUIPMENT MANUFACTURING CO LTD

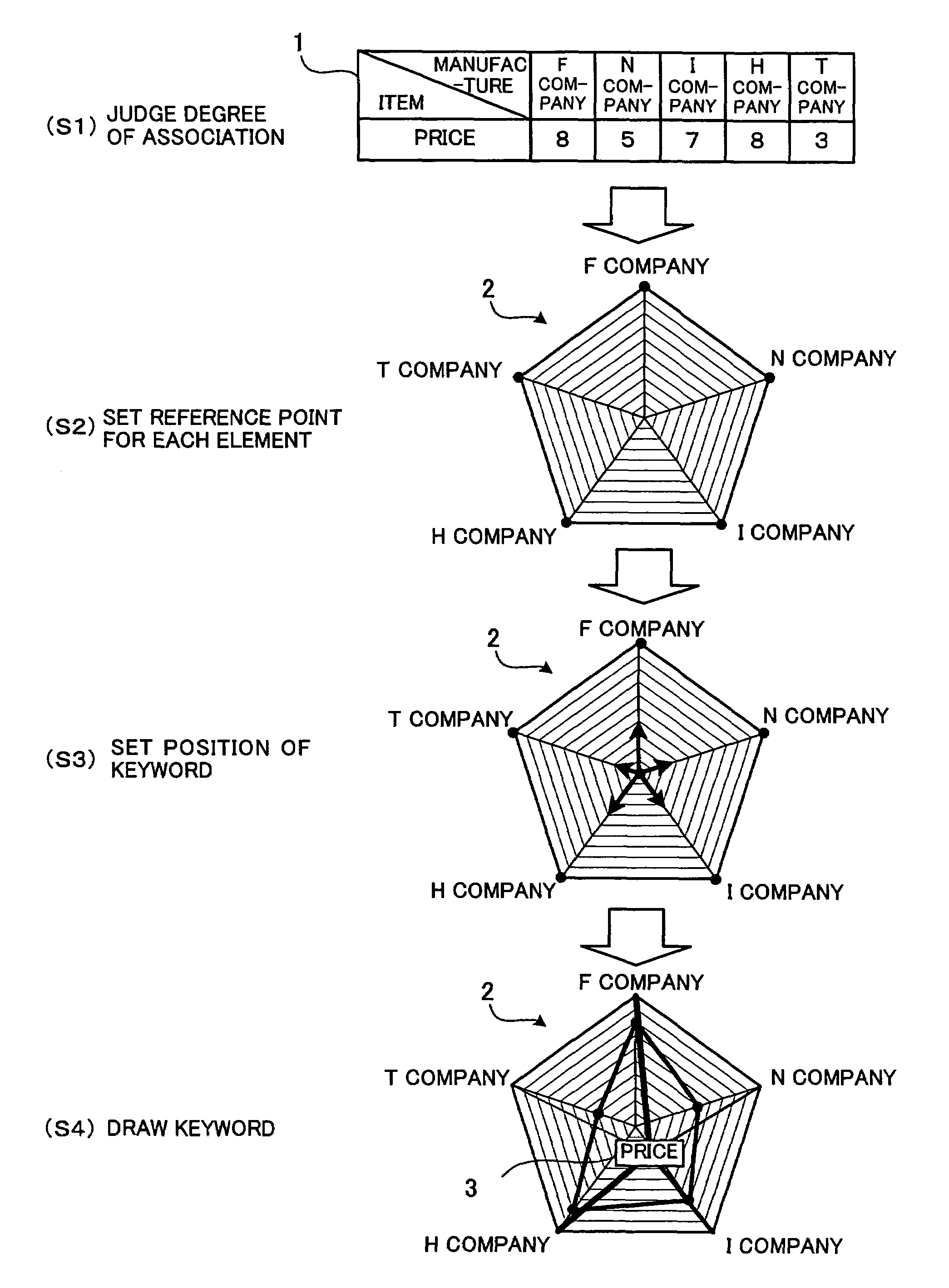

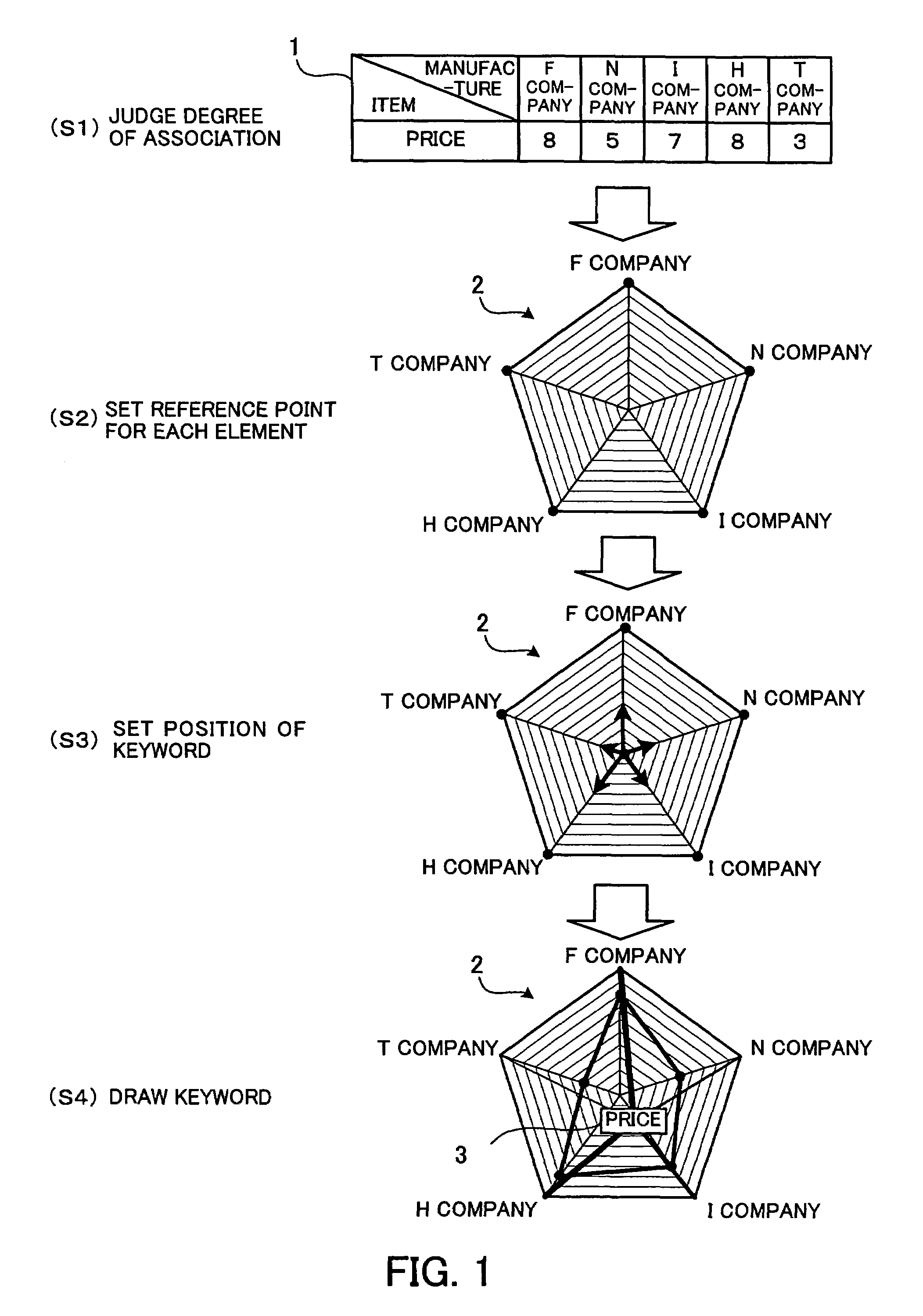

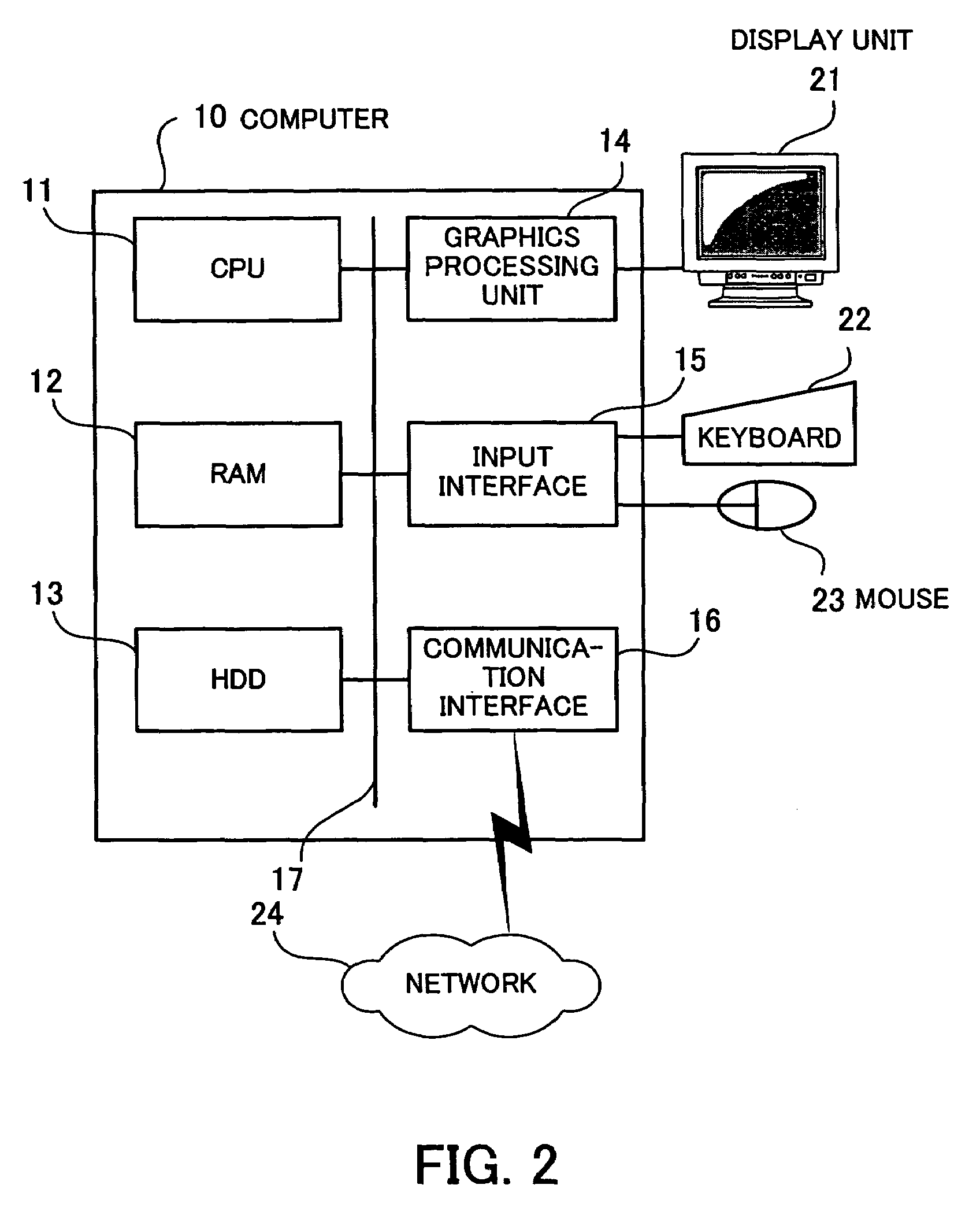

Program and method for displaying a radar chart

InactiveUS7290212B2High degree of associationDigital data information retrievalDrawing from basic elementsRadarComputer science

With spreadsheet software, such as the MICROSOFT EXCEL, a radar chart can be compiled by the use of data in a table made.

Owner:FUJITSU LTD

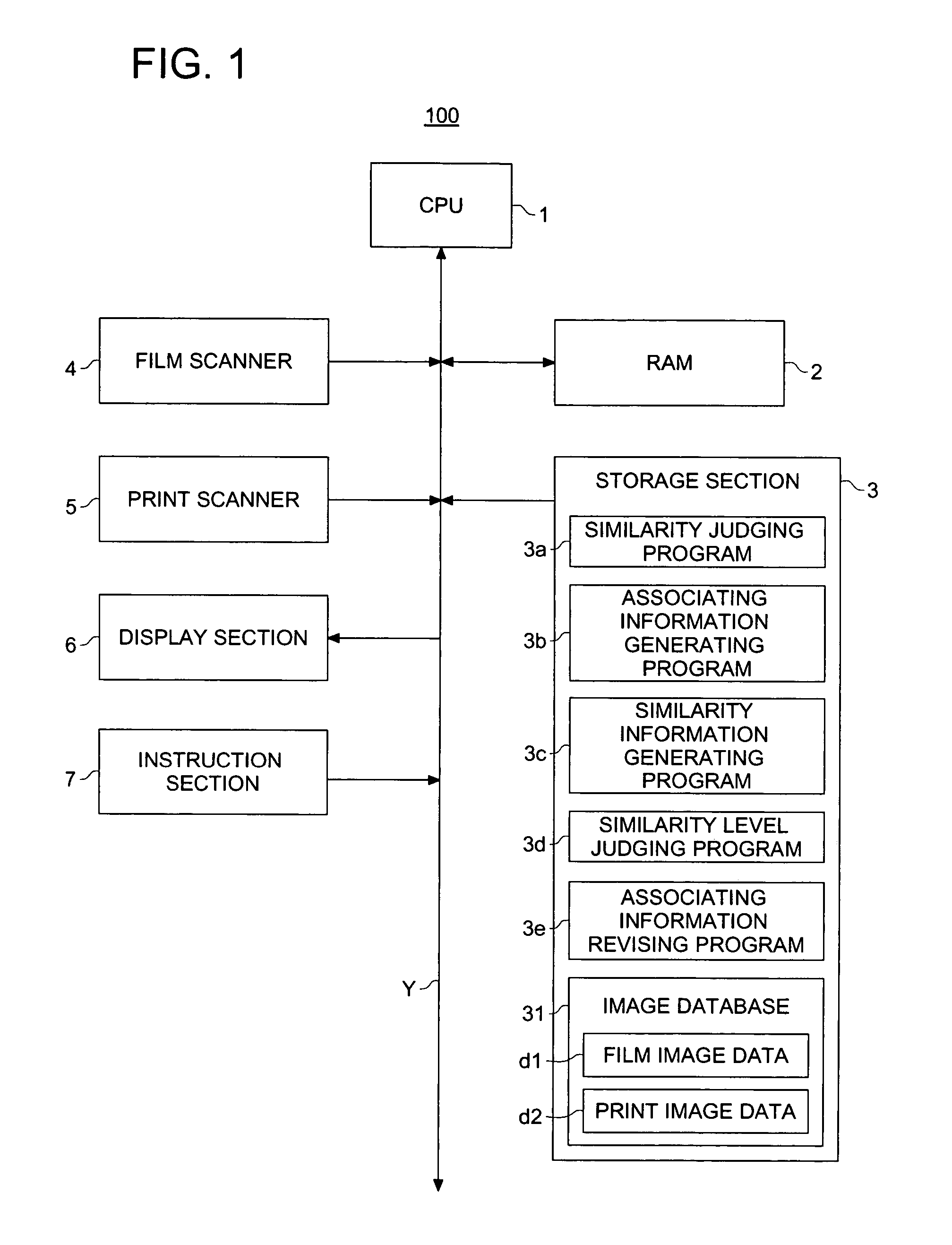

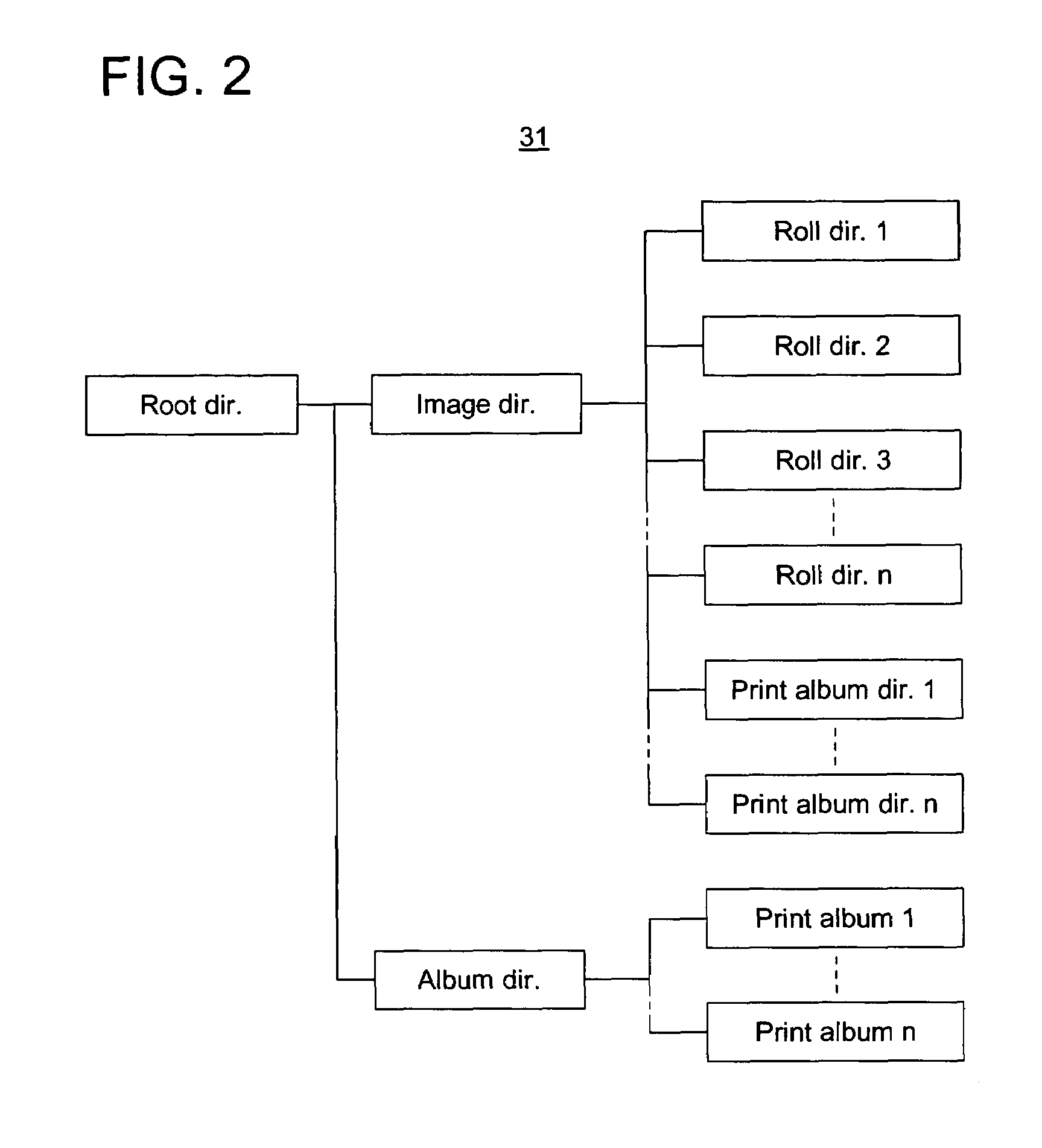

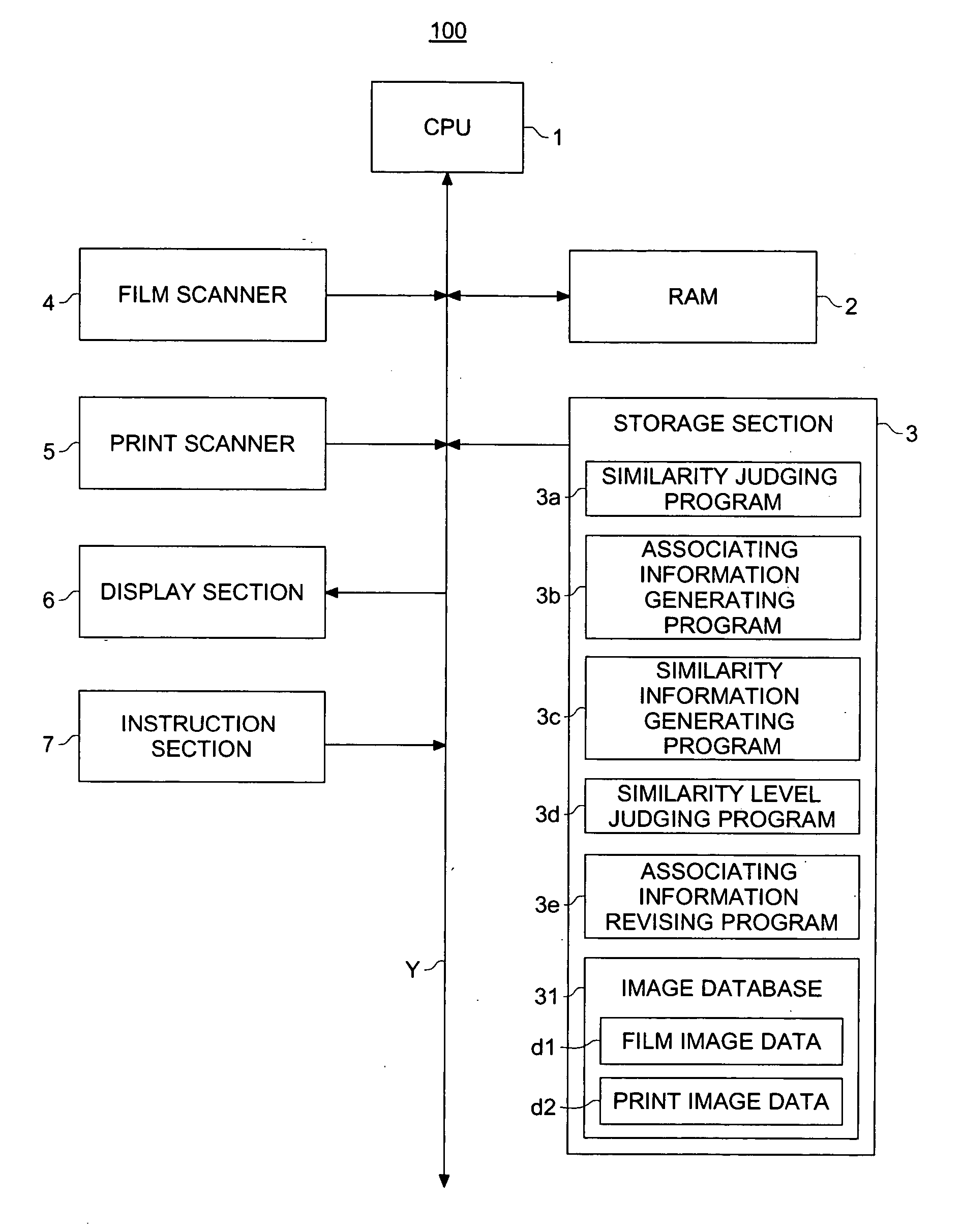

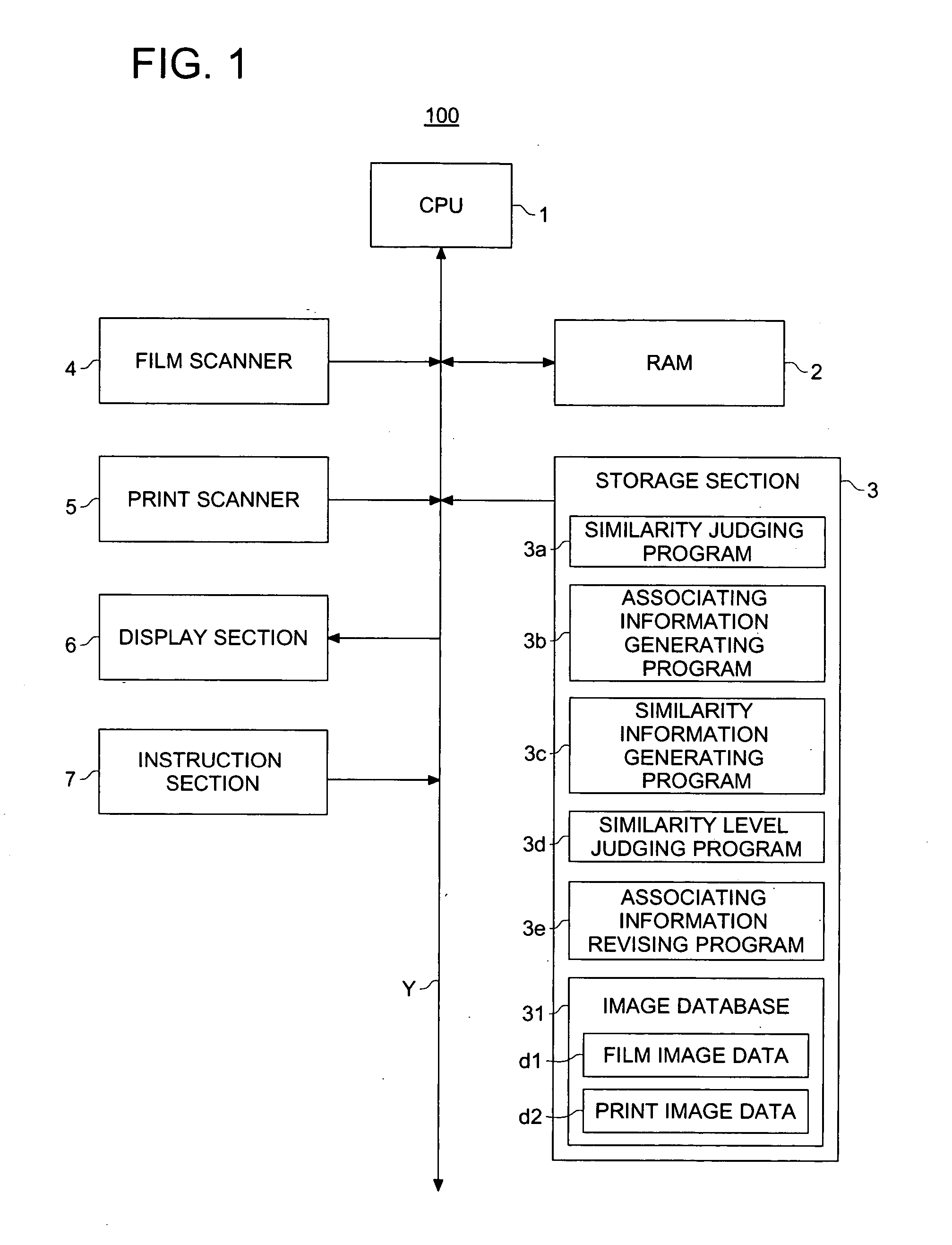

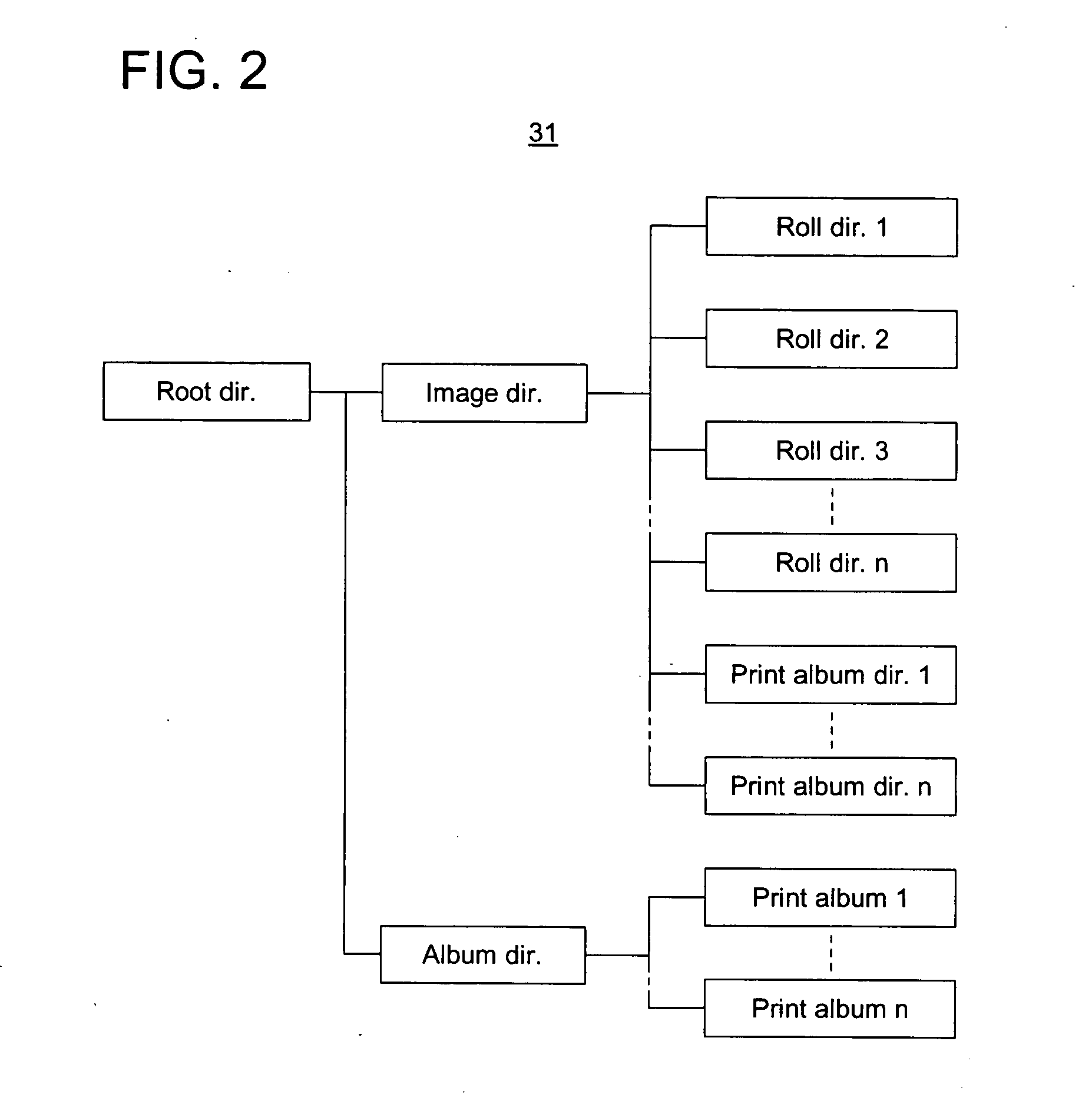

Image control apparatus, image control method and program

InactiveUS7515754B2Easy to usePrecise arrangementImage analysisData processing applicationsComputer scienceControl equipment

An image control apparatus having an image database storing plural pieces of image information, for controlling the plural pieces of image information, the image control apparatus including: a first image information acquiring device for acquiring first image information; a second image information acquiring device for acquiring second image information; a similarity determining section for determining a similarity through comparison between the first image information and the second image information; and an associating information generating section for generating associating information to associate the first image information with the second image information, based on a judgment result of the similarity determining section, wherein the plural pieces of image information are controlled based on the associating information generated by the associating information generating section.

Owner:KONICA MINOLTA INC

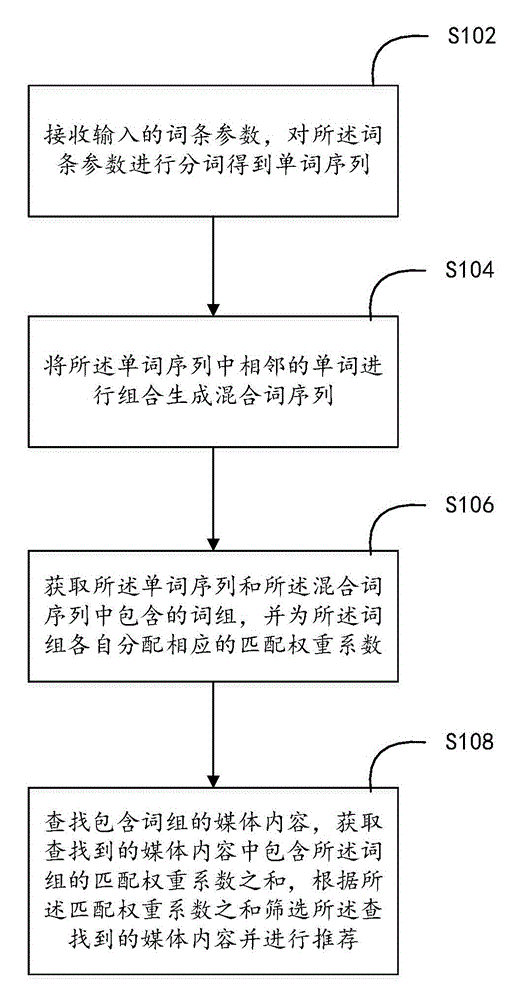

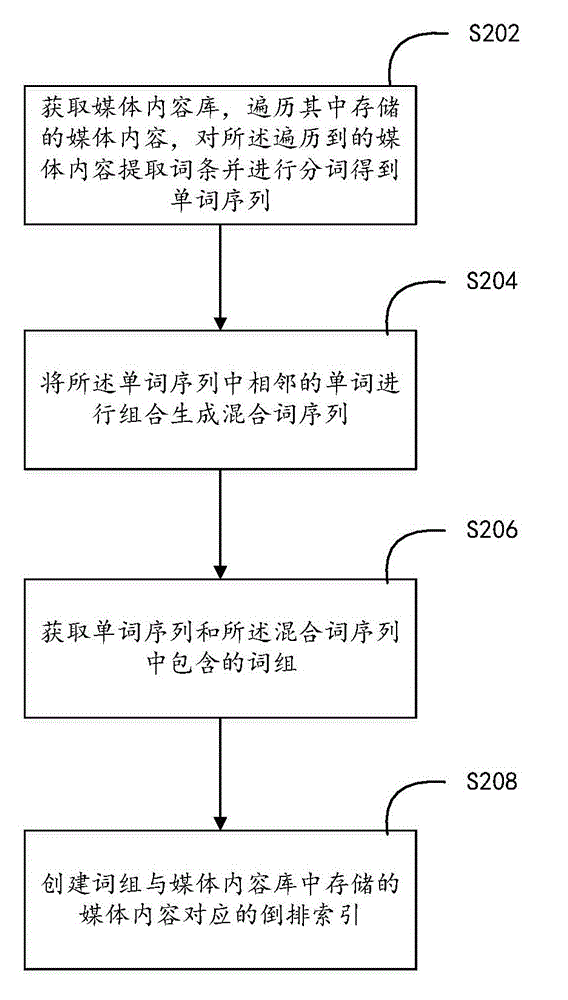

Media content recommendation method and device

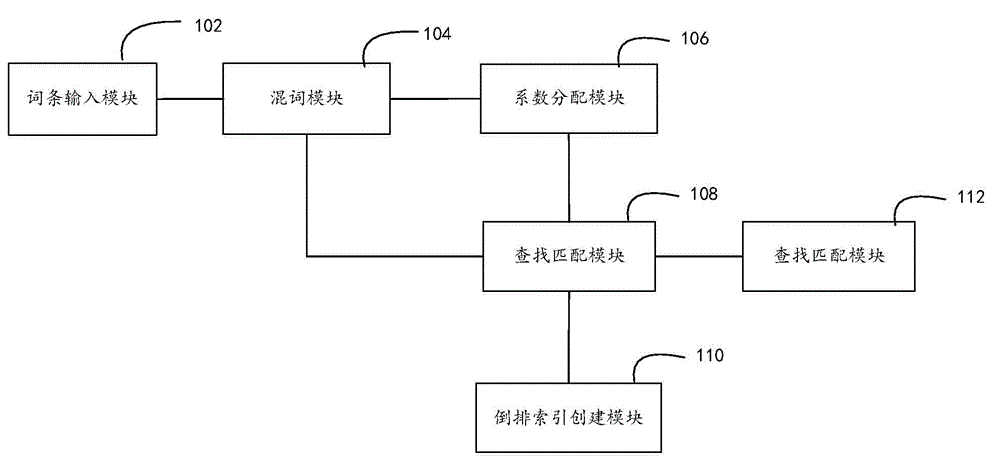

ActiveCN104978314AHigh degree of associationImprove accuracyWeb data indexingSpecial data processing applicationsMediaFLOWord group

A media content recommendation method includes: receiving an input entry parameter, and performing word segmentation on the entry parameter to obtain a word sequence; combining adjacent words in the word sequence to generate a mixed word sequence; acquiring phrases included in the word sequence and the mixed word sequence, and separately allocating a corresponding matching weight coefficient to a phrase; searching for media content including the phrase, acquiring a matching weight coefficient sum of phrases included in the found media content, and screening the found media content according to matching weight coefficient sums and performing recommendation. In addition, a media content recommendation apparatus is also provided.

Owner:SHENZHEN TENCENT COMP SYST CO LTD

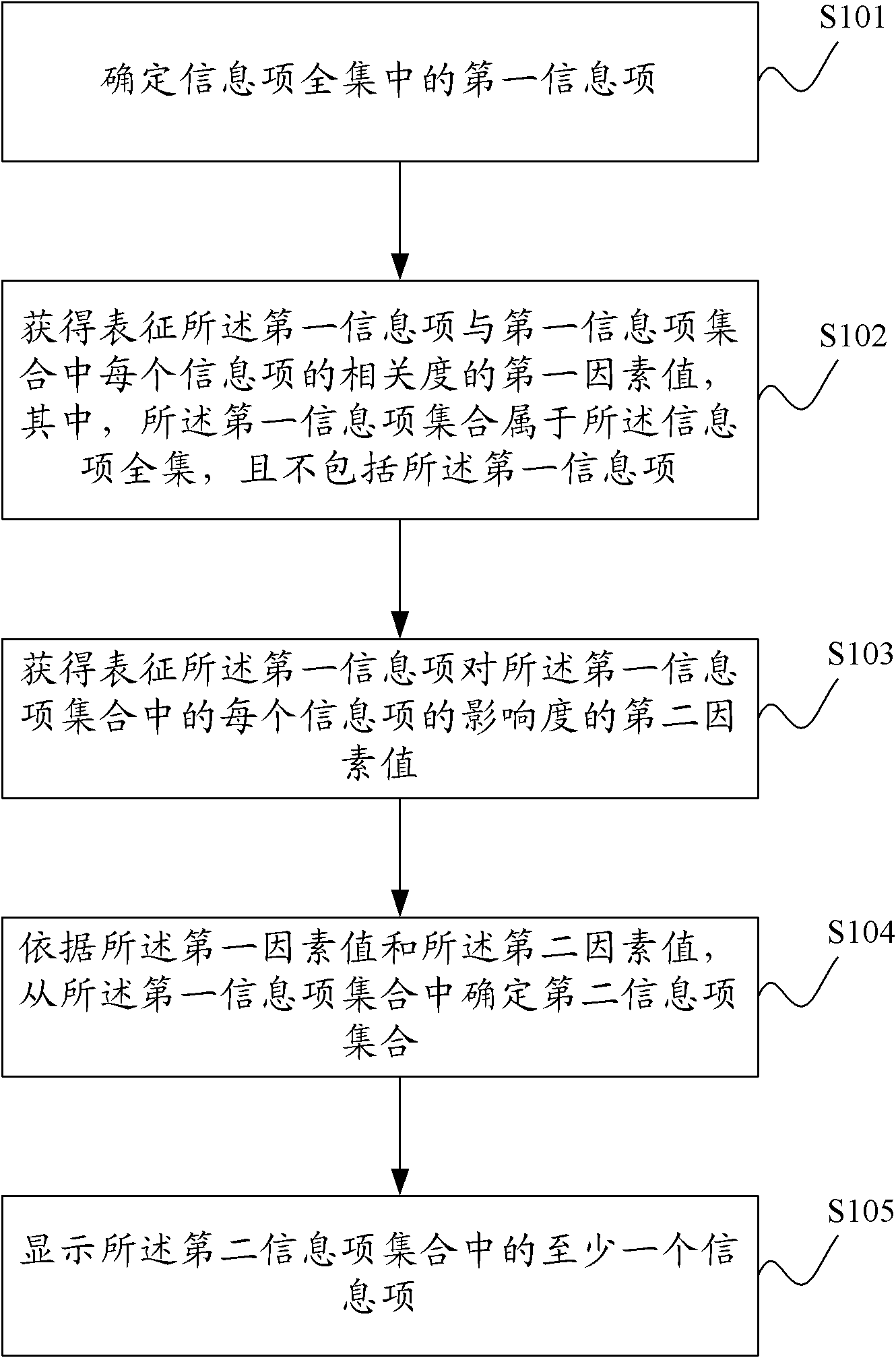

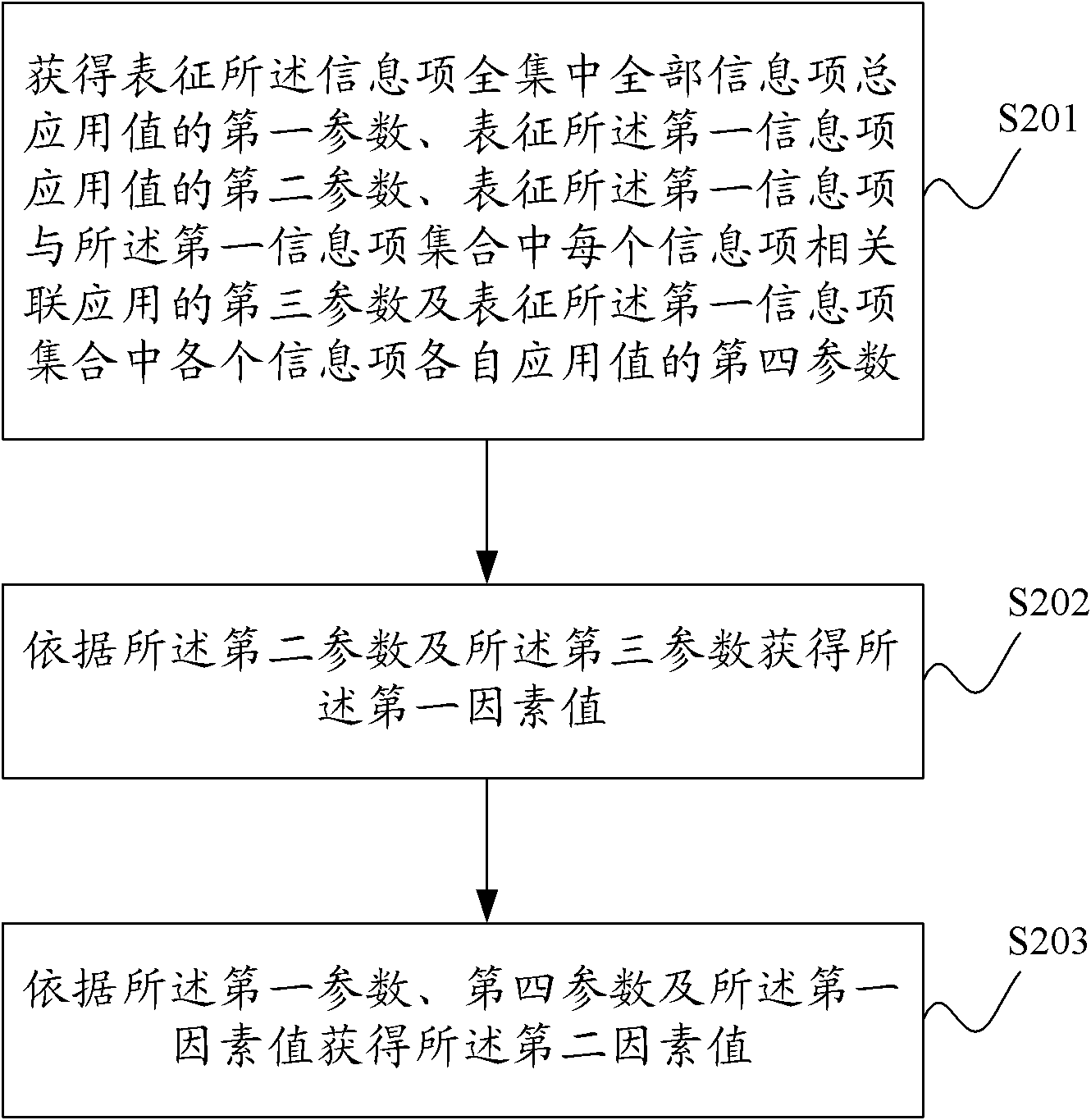

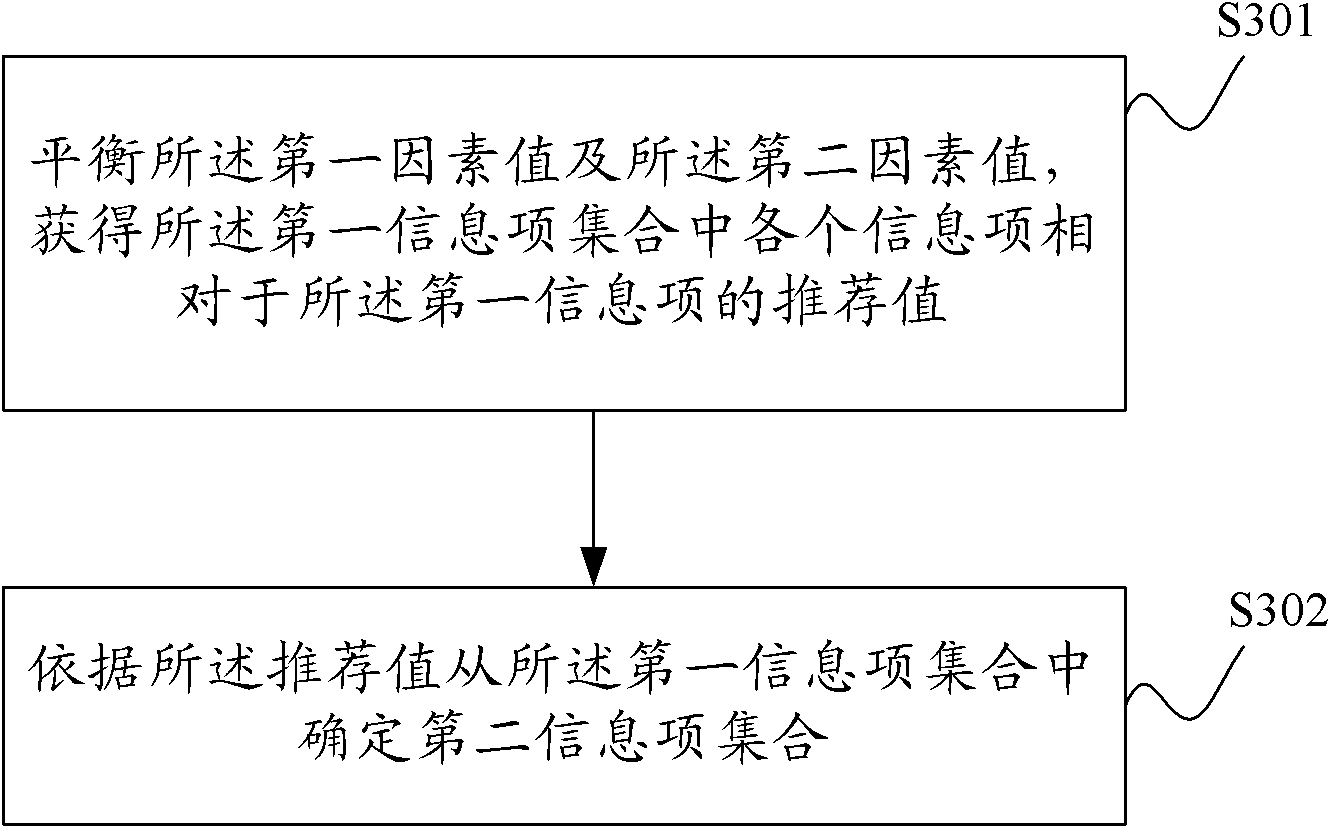

Information item recommendation method and system

ActiveCN103218726AMeets requirementsHigh degree of associationSpecial data processing applicationsMarketingRelevant informationData mining

The invention provides an information item recommendation method and system. The information item recommendation method comprises the steps of determining a first information item in an information item universal set; obtaining a first factor value representing the relevant degree between the first information item and each information item in a first information item set, wherein the first information item set belongs to the information item universal set and does not include the first information item; obtaining a second factor value representing the influence degree between the first information item and each information item in the first information item set; determining a second information item set from the first information item set according to the first factor value and the second factor value; and displaying at least one information item in the second information item set. According to the information item recommendation method and system, relevant information items recommended to a user is high in relevant degree, the recommended information items meet requirements of the user, and the precision rate of recommendation is high.

Owner:LENOVO (BEIJING) LTD

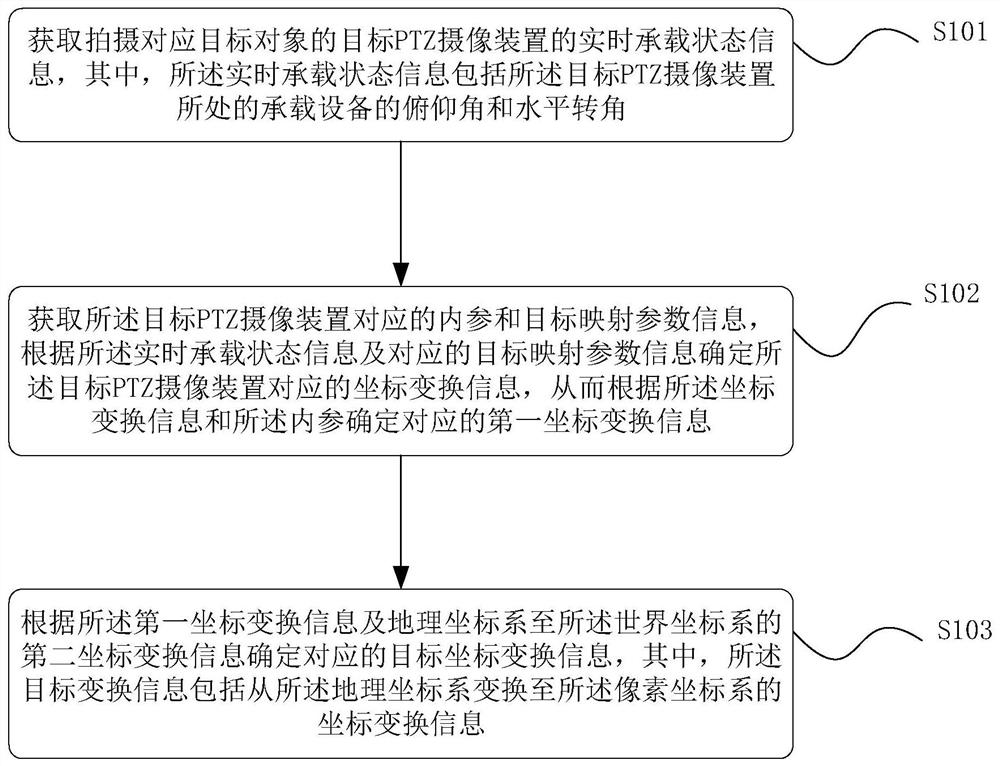

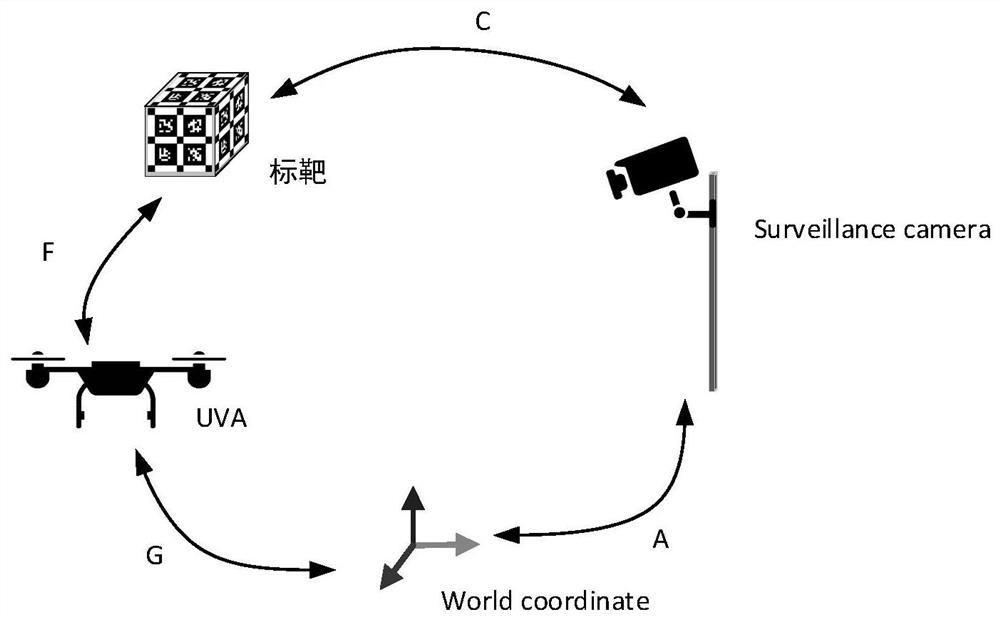

Method and equipment for determining target coordinate transformation information

ActiveCN113345028AImprove Image UtilizationIncrease profitImage enhancementImage analysisPattern recognitionComputer graphics (images)

The invention aims to provide a method and equipment for determining target coordinate transformation information. The method specifically comprises the following steps: acquiring real-time bearing state information of a target PTZ (Pan / Tilt / Zoom) camera shooting a corresponding target object; obtaining an internal reference and target mapping parameter information corresponding to the target PTZ camera device, determining coordinate transformation information corresponding to the target PTZ camera device according to the real-time bearing state information and the corresponding target mapping parameter information, and determining corresponding first coordinate transformation information according to the coordinate transformation information and the internal reference; and determining corresponding target coordinate transformation information according to the first coordinate transformation information and second coordinate transformation information from the geographic coordinate system to the world coordinate system. According to the method and the device, coordinate transformation of the image frame and the electronic map in the PTZ camera device can be realized, so that data linkage of the GIS information in the electronic map and the shot image frame is completed, and the image utilization rate of the PTZ camera device is improved.

Owner:HISCENE INFORMATION TECH CO LTD

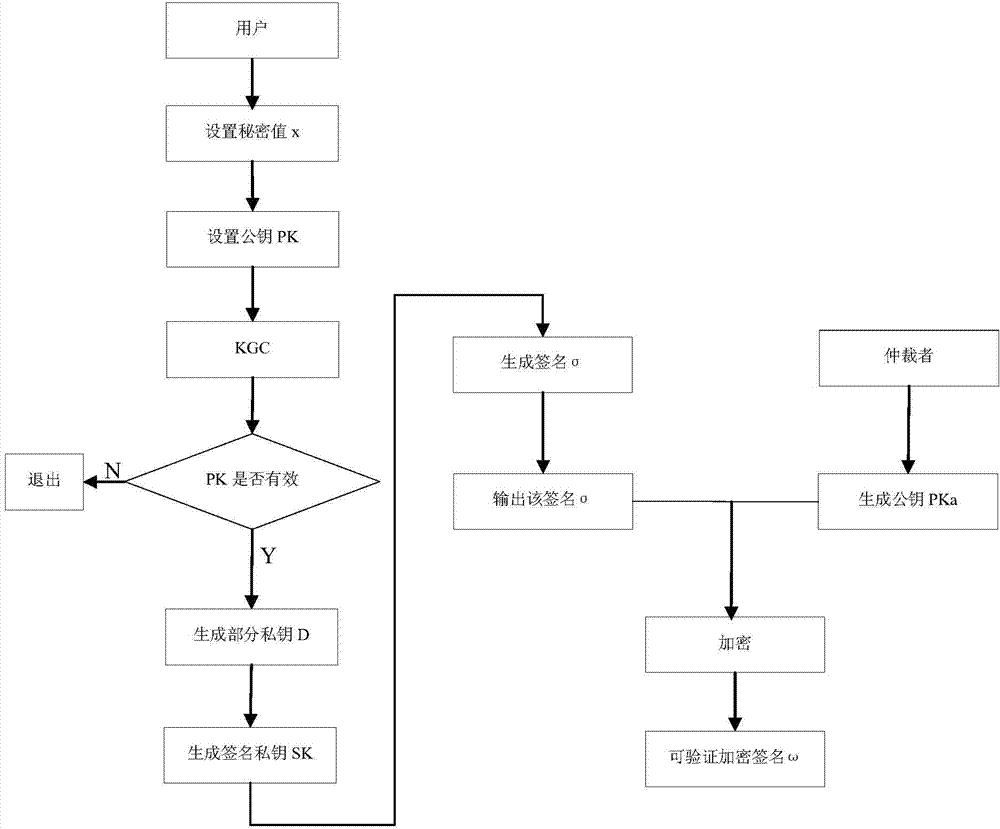

Certificateless verifiable encrypted signature method with forward security

InactiveCN104780047AResistant to Substitution AttacksHigh degree of associationUser identity/authority verificationHash functionTimestamp

The invention provides a certificateless verifiable encrypted signature method with forward security, and belongs to the technical field of computer network and information security. According to the method, the timestamp is embedded into secret values of a certificateless signature algorithm, secret values which are not used is safely deleted, and signature key evolution and digital signature are really combined; a traditional certificateless signature algorithm sequence is changed, the set secrete values are generated before part of private keys are generated, meanwhile, public keys are bound to a Hash function, the parameter correlation degree in the signature algorithm is increased, and two types of enemy attacks of the certificateless environment are resisted; a generated verifiable encrypted signature comprises the user secret values and has the forward security; the computation burden of a signature scheme is small, the signature is short, and the whole performance is advantageous. The certificateless verifiable encrypted signature method with the forward security has very high security and fairness.

Owner:NANJING UNIV OF POSTS & TELECOMM

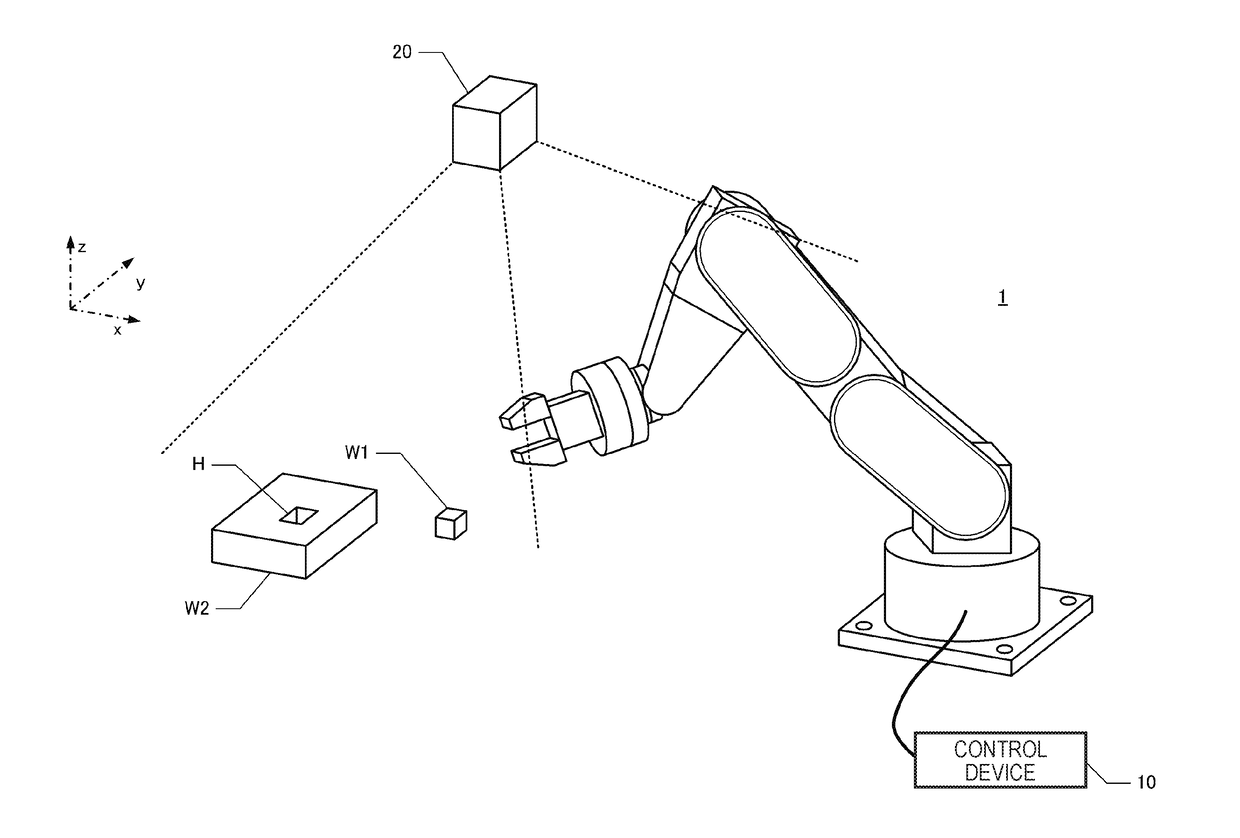

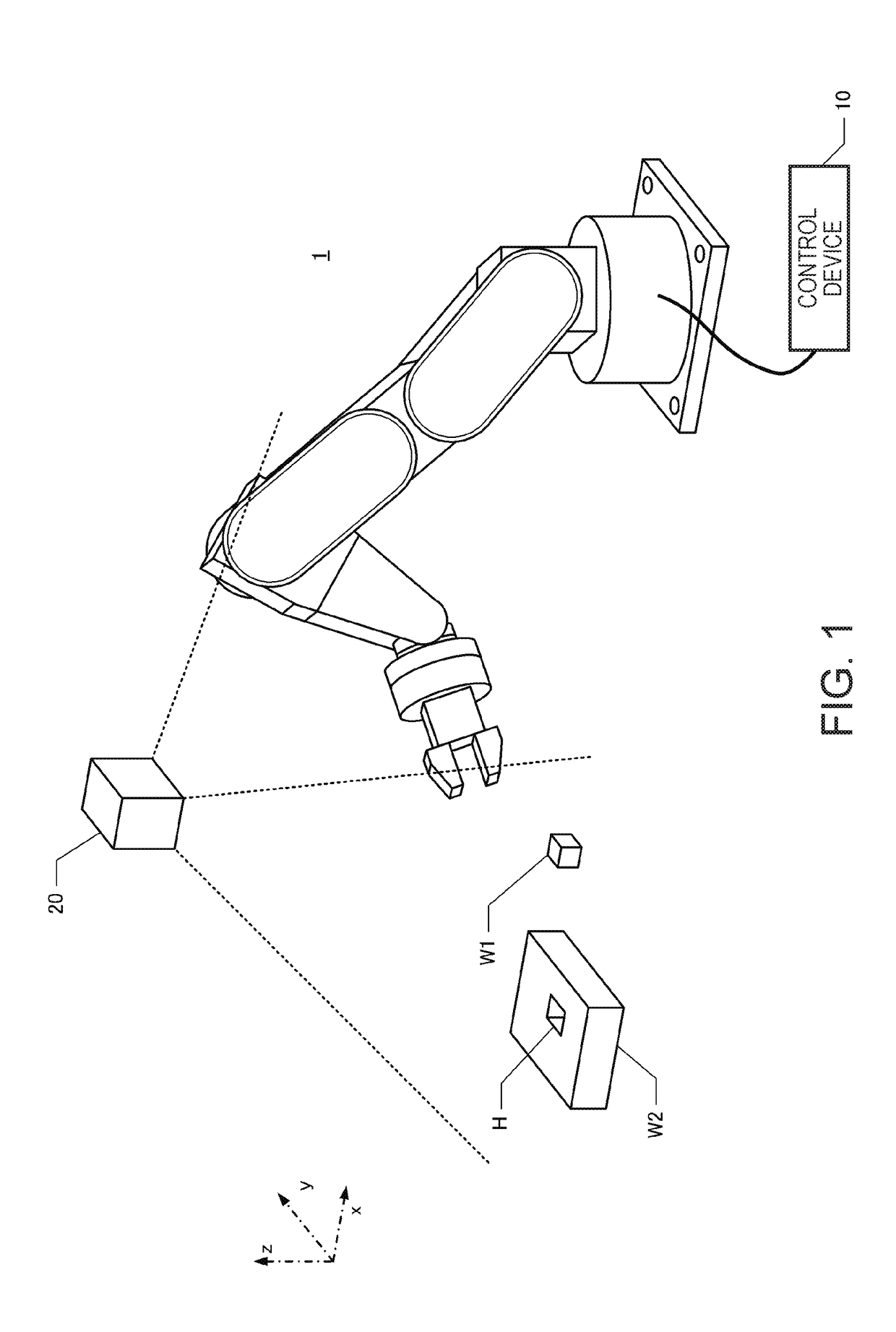

Object attitude detection device, control device, and robot system

ActiveUS20180285684A1Easy to detectRaise the possibilityProgramme controlProgramme-controlled manipulatorRobotic systemsDegree of similarity

An object attitude detection device includes: a picked-up image acquisition unit which acquires a picked-up image of an object; a template image acquisition unit which acquires a template image for each attitude of the object; and an attitude decision unit which decides an attitude of the object, based on the template image having pixels such that a distance between pixels forming a contour in the picked-up image and pixels forming a contour of the template image is shorter than a first threshold and that a degree of similarity between a gradient of the pixels forming the contour in the picked-up image and a gradient of the pixels forming the contour of the template image is higher than a second threshold.

Owner:SEIKO EPSON CORP

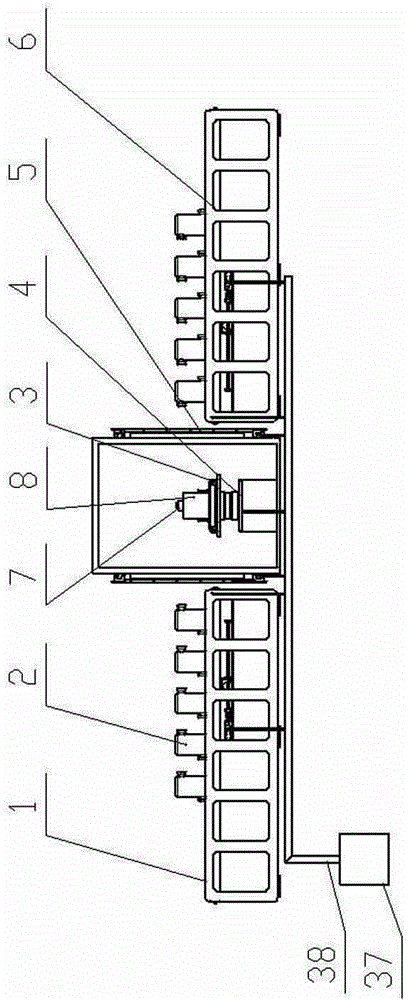

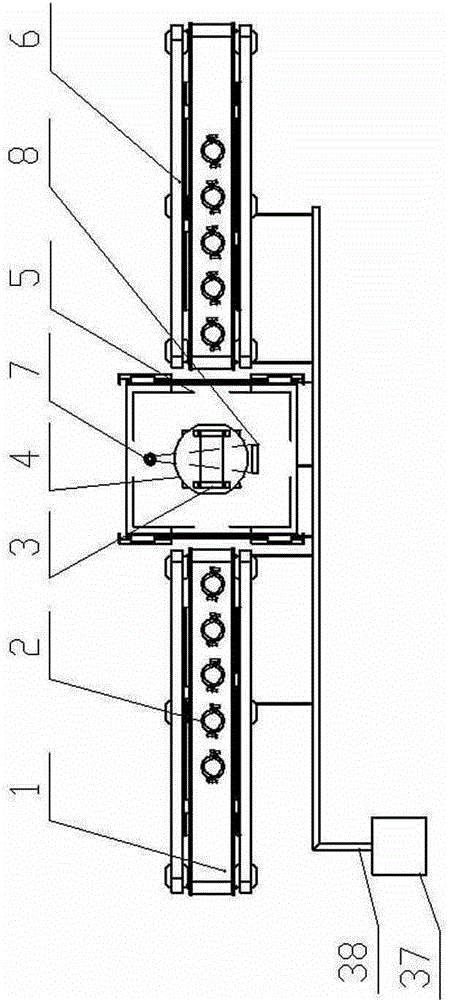

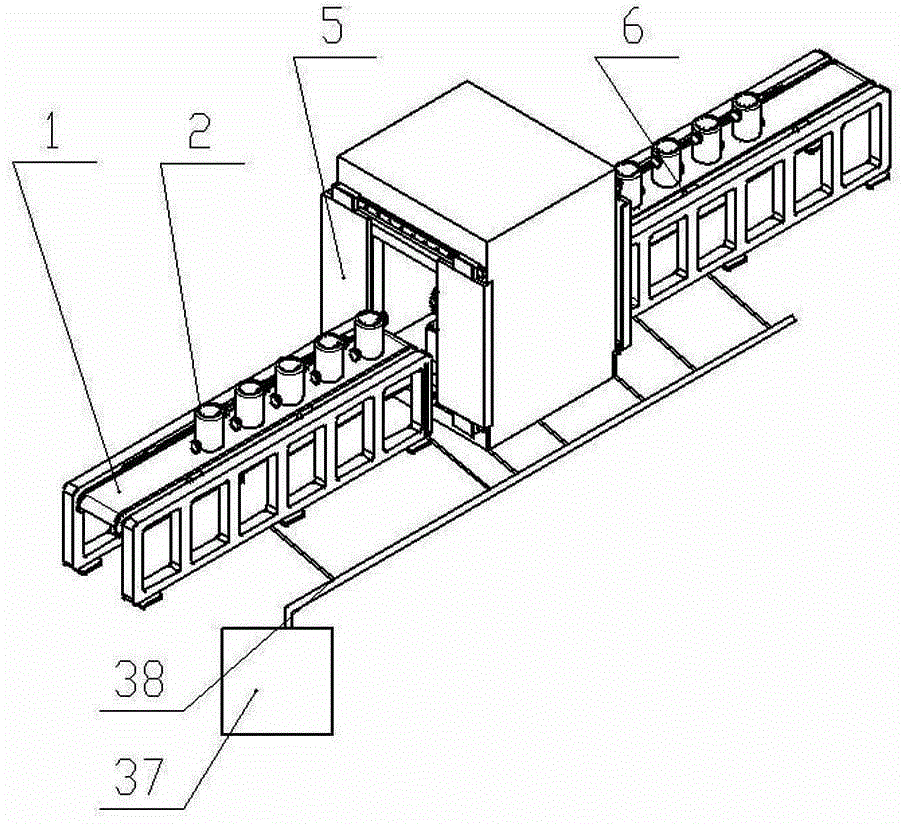

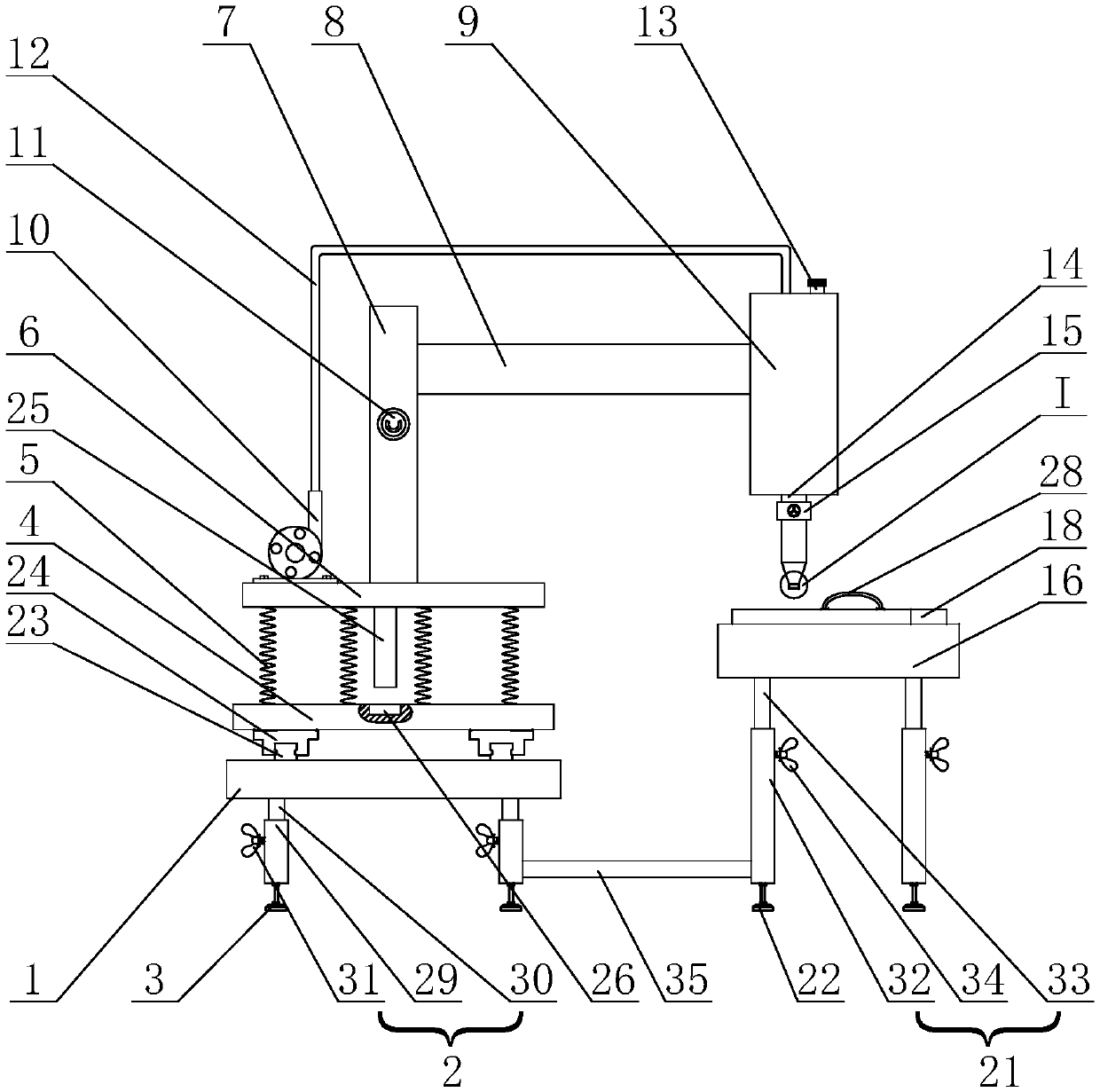

Online CT (computed tomography) nondestructive testing device

ActiveCN104458769AFast shippingShipped accuratelyMaterial analysis using wave/particle radiationFlat panel detectorComputed tomography

Disclosed is an online CT (computed tomography) nondestructive testing device. A testing platform is mounted in a protective lead room, an X-ray tube and a flat-panel detector are fixed on the left wall and the right wall of a lead room frame in the protective lead room respectively, a feeding conveying line and a discharging conveying line are mounted on the left side and the right side of the protective lead room, a platform conveying line is mounted on the testing platform, and control signal input ends and control signal output ends of components controlled by a control device are connected with an input end and an output end of the control device through cables. The device is high in conveying accuracy and automation degree and convenient to operate, a workpiece can be rapidly and accurately conveyed to the test position, the association degree between all actions is high, the workpiece can enter and exit the device by one key, an X-ray begins to acquire an image, the position of the workpiece can be manually adjusted through an imaging screen when deviating, the X-ray does not need to be closed, and the service life of the X-ray tube is prolonged.

Owner:DONGDAN AOLONG RADIATIVE INSTR GRP

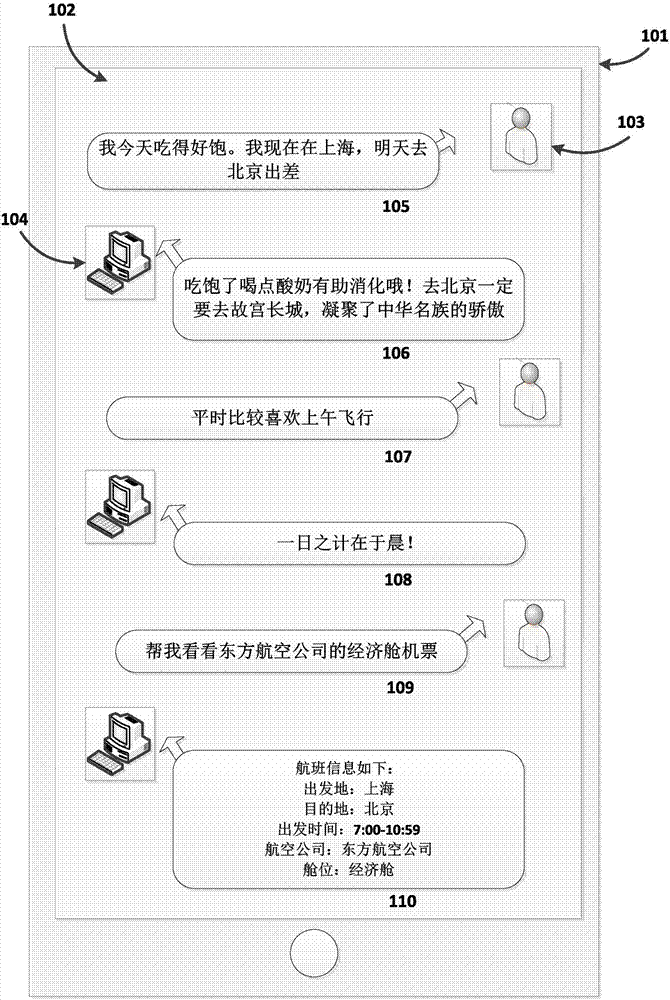

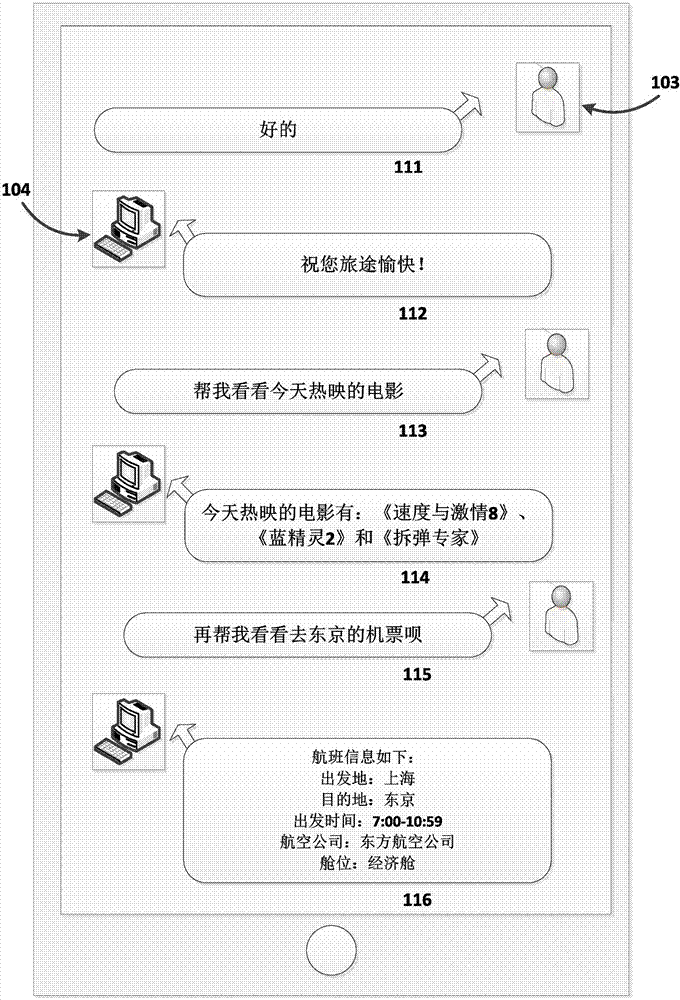

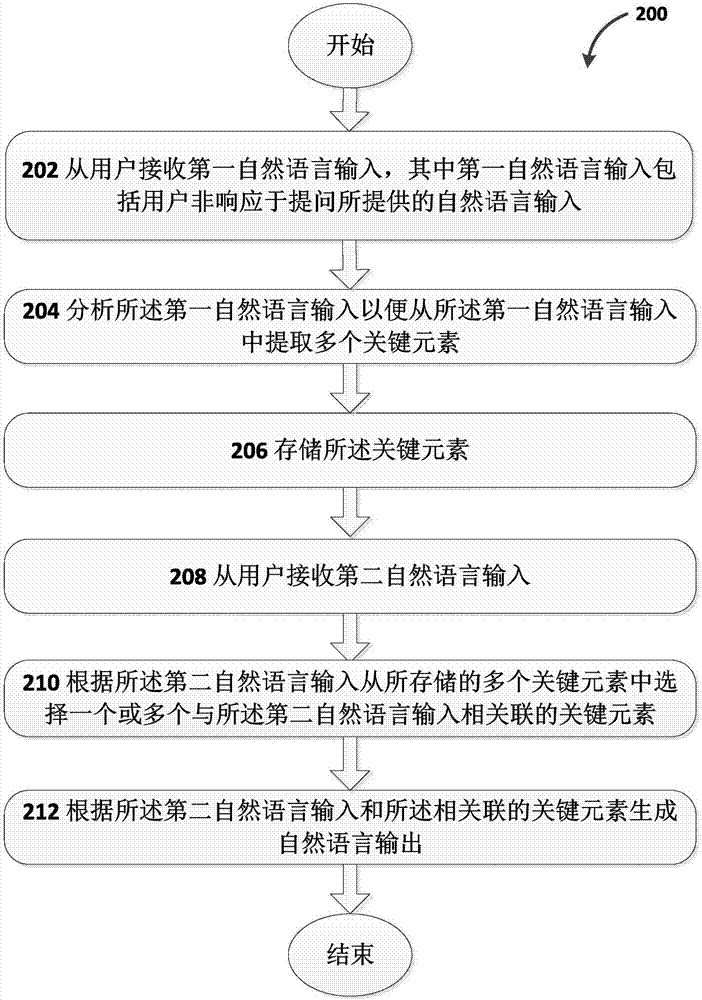

Interactive-context-based natural language processing method

ActiveCN107239450AGuaranteed continuityDisambiguationNatural language translationSemantic analysisContext processingContext based

The invention discloses an interactive-context-based natural language processing method. The method comprises the following steps of receiving first natural language input from a user, wherein the first natural language input comprises natural language input provided by not responding to question asking by the user; analyzing the first natural language input so that multiple key elements can be extracted from the first natural language input; storing the key elements; receiving second natural language input from the user; according to the second natural language input, selecting one or more key elements associated with the second natural language input from the multiple stored key elements; according to the second natural language input and the associated key elements, generating natural language output. According to the method, the mode that a robot obtains useful information can be expanded, and the scene interactive continuity can be ensured.

Owner:上海对岸信息科技有限公司

Waterborne wood coating with zero VOC volatilization and preparation method of waterborne wood coating

ActiveCN106243984AGood film formingHigh degree of associationFireproof paintsPolyurea/polyurethane coatingsChemistryCastor oil

The invention relates to the technical field of waterborne coatings, in particular to a waterborne wood coating with zero VOC volatilization and a preparation method of the waterborne wood coating. The waterborne wood coating comprises a component A, a component B and water, wherein the component A comprises the following raw materials in parts by weight: starch, castor oil, emulsifiers, a preservative, a water-based defoamer, an aqueous catalyst and purified water, and the component B is water dispersible type modified polyisocyanate; the ratio in parts by weight of the component A to the component B to water is 1: (0.3-1): (0.3-1). The waterborne wood coating with the zero VOC volatilization disclosed by the invention takes the castor oil and starch as raw materials, thereby being natural and environment-friendly, free of toxicity and having good cold resistance, heat resistance, dryness resistance and humidity resistance, excellent adhesion and high impact resistance; furthermore, the method is low in input equipment cost, simple and convenient in process and easy to operate.

Owner:董武齐

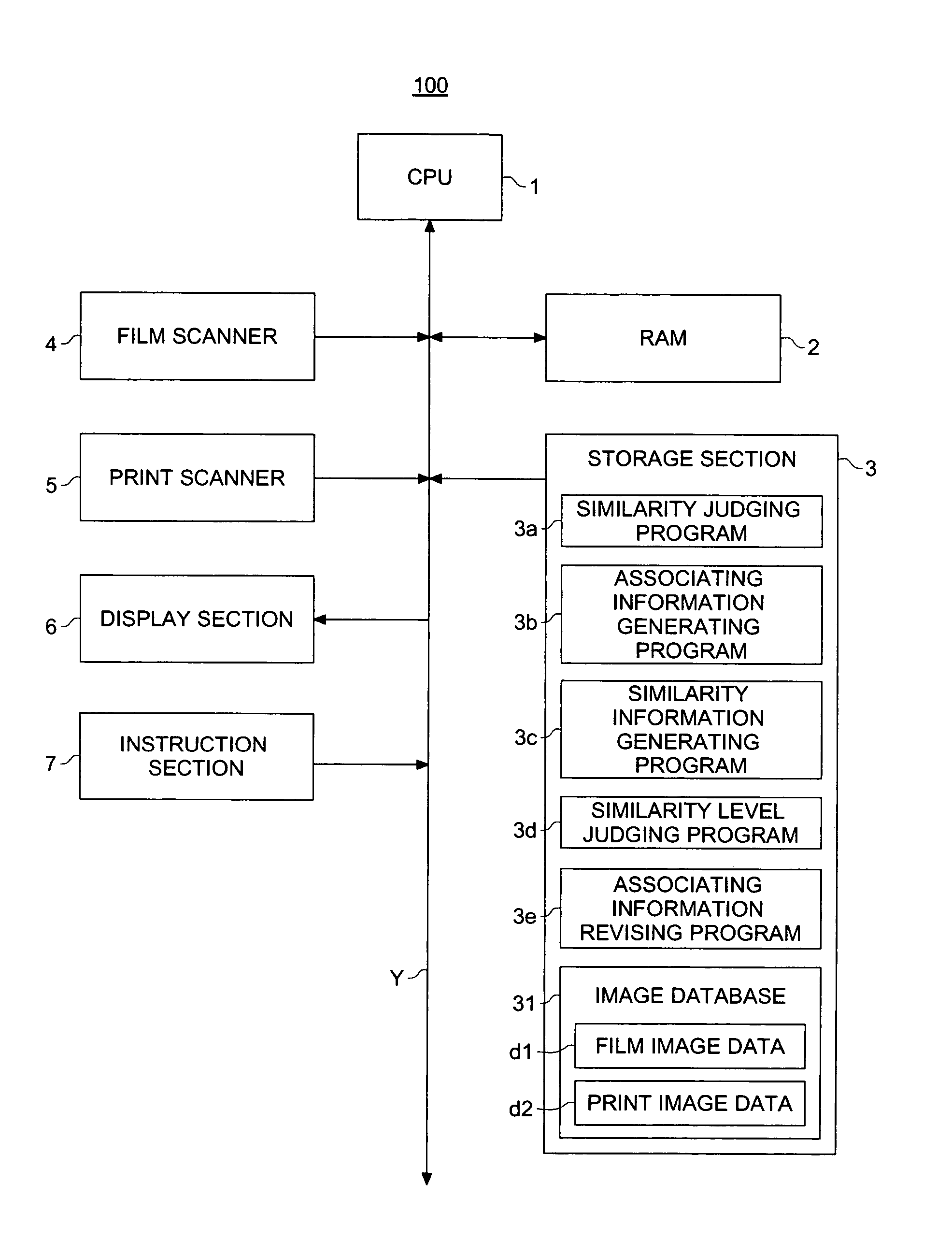

Image control apparatus, image control method and program

InactiveUS20050125454A1Precise arrangementEasy to useData processing applicationsImage analysisControl equipmentImage database

An image control apparatus having an image database storing plural pieces of image information, for controlling the plural pieces of image information, the image control apparatus including: a first image information acquiring device for acquiring first image information; a second image information acquiring device for acquiring second image information; a similarity determining section for determining a similarity through comparison between the first image information and the second image information; and an associating information generating section for generating associating information to associate the first image information with the second image information, based on a judgment result of the similarity determining section, wherein the plural pieces of image information are controlled based on the associating information generated by the associating information generating section.

Owner:KONICA MINOLTA INC

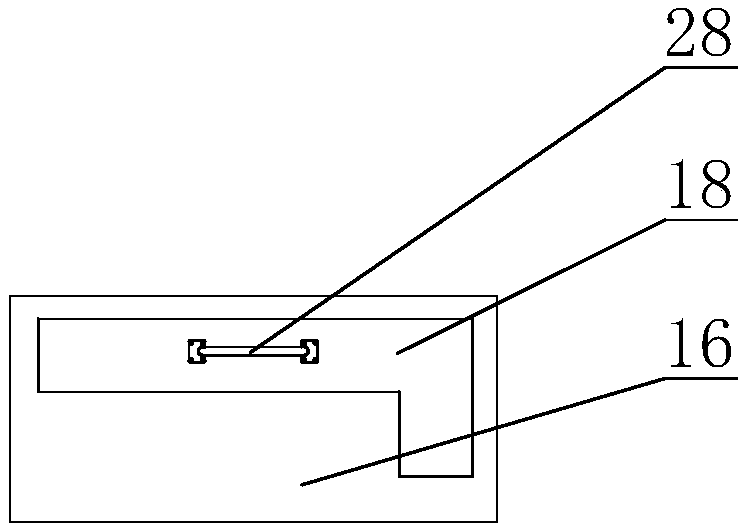

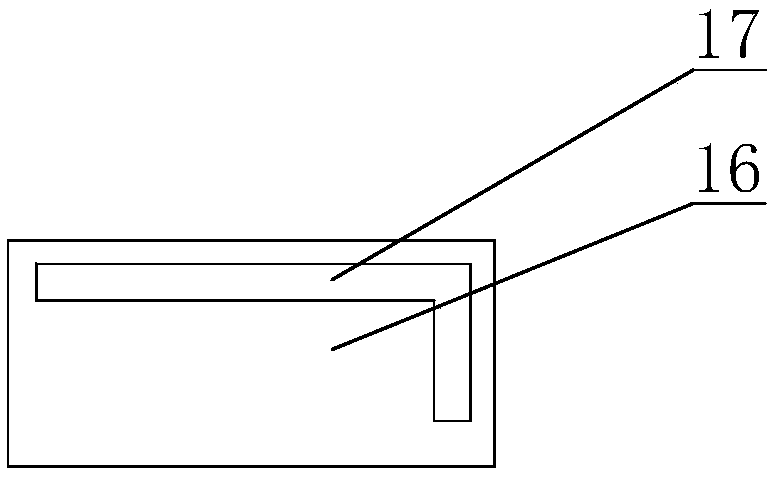

Gluing device for accountant

ActiveCN109605974AFlexible control of the stroke of smearingImprove the efficiency of smearing and bondingBookbinding adhesiveFixed frameEngineering

The invention discloses a gluing device for an accountant, and relates to the field of office supplies. The gluing device comprises a fixed plate. A sliding plate is arranged on the upper portion of the fixed plate and is in sliding connection with the fixed plate. Springs are arranged on the sliding plate and are compression springs. An adjusting plate is arranged on the springs and provided withan operation rod. A first connecting rod is arranged on one side of the operation rod. A glue box is arranged at the end, away from the operation rod, of the first connecting rod. A pressurization device is arranged on the glue box and comprises a gas pump. A gas pump switch is arranged on the operation rod. A gas conveying pipe is arranged on the gas pump. A glue adding pipe is arranged on the glue box. A glue outlet pipe is arranged at the bottom of the glue box and provided with a valve. A containing plate is arranged below the glue outlet pipe and provided with a sliding groove. A paper fixing frame is arranged on the containing plate. Multiple second supporting rods are arranged below the containing plate. The gluing device has the beneficial effects that the glue application strokecan be flexibly adjusted, the process and time of layer-by-layer bonding of data paper are shortened, and the application and bonding efficiency is improved.

Owner:JIANGSU INST OF ECONOMIC & TRADE TECH

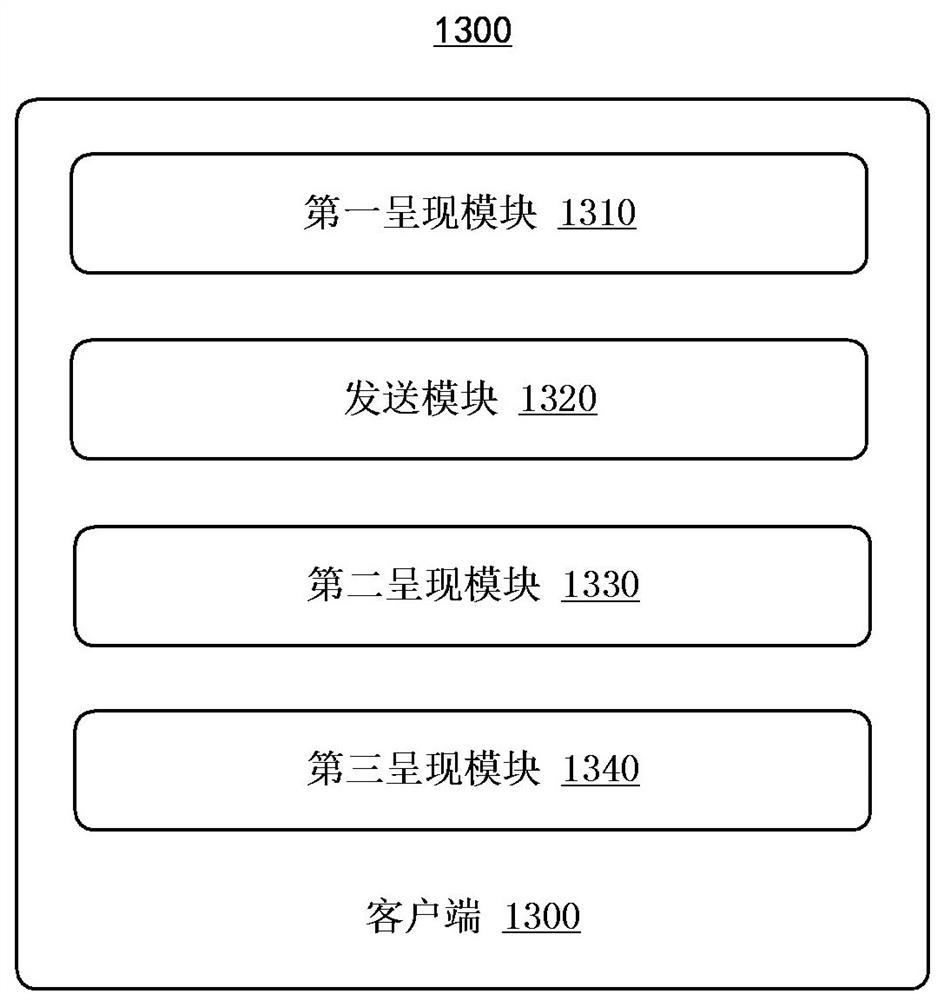

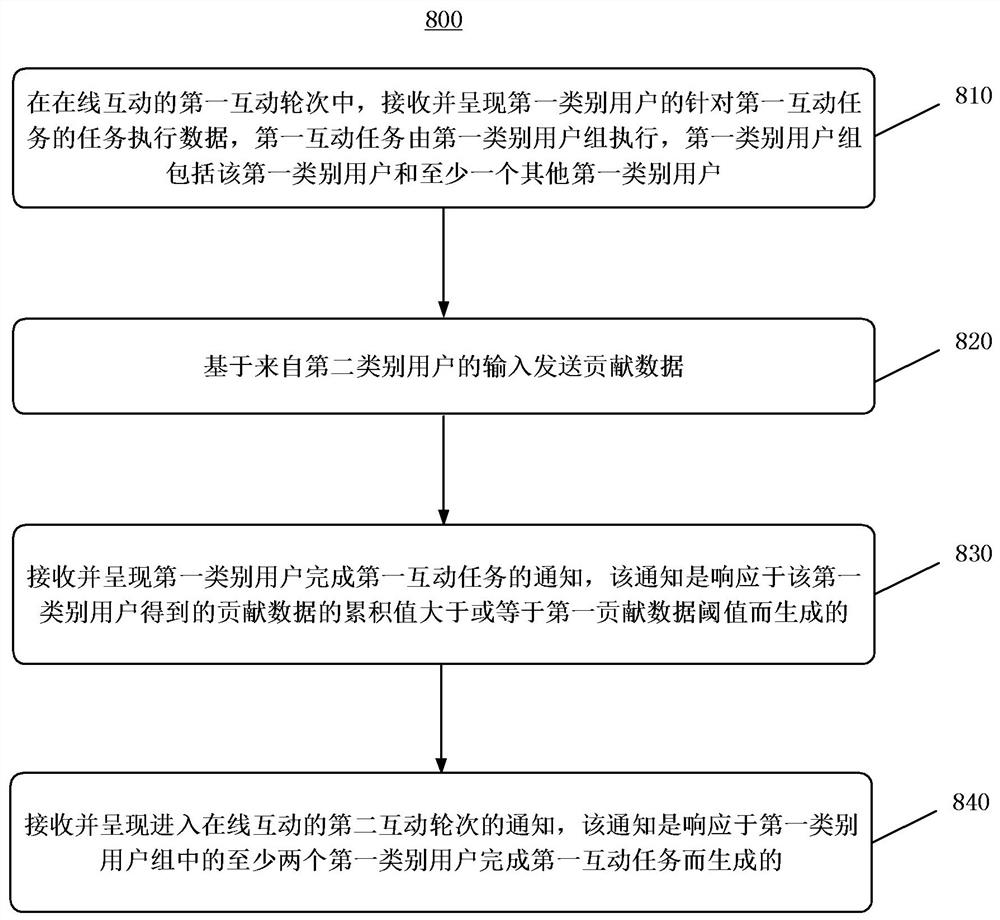

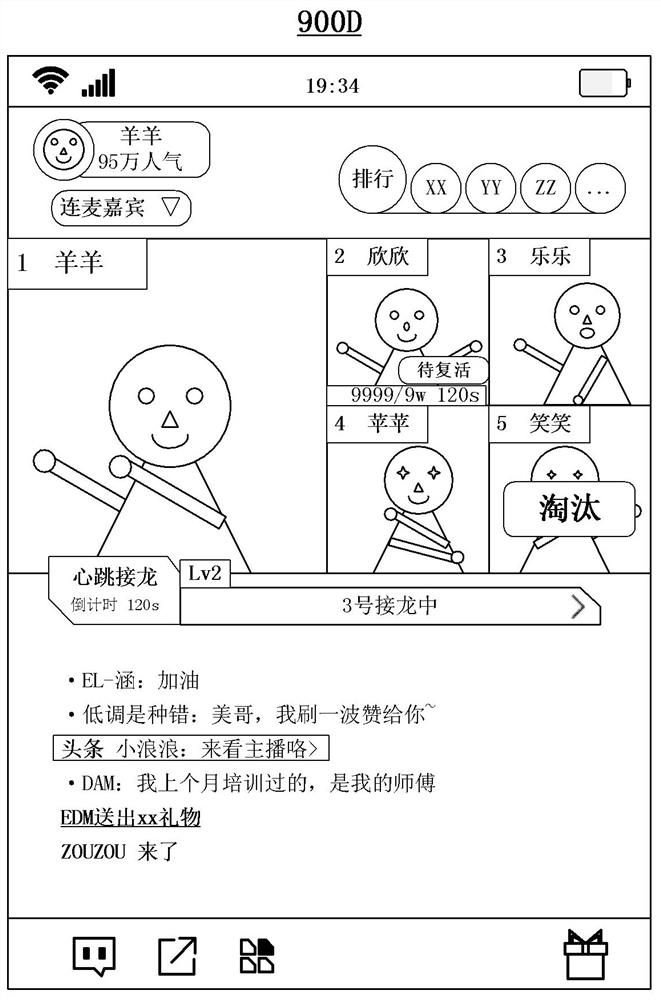

Online interaction method, client, server, computing device and storage medium

ActiveCN112423013AIncrease intent to engageImprove utilization efficiencySelective content distributionComputer networkUser participation

The invention provides an online interaction method for a client. The method comprises the following steps: in a first interaction round of online interaction, sending task execution data for a firstinteraction task based on input from a first category of users, and the first interaction task is executed by a first category user group comprising the first category of users and at least one otherfirst category of users; receiving and presenting a notification that the first category of users complete the first interaction task, the notification being generated in response to an accumulated value of contribution data obtained by the first category of users being greater than or equal to a first contribution data threshold, the contribution data being provided by a second category of usersbased on task execution data; and receiving and presenting a notification of entering a second interaction round of the online interaction, wherein the notification is generated in response to the fact that at least two first category of users in the first category user group complete the first interaction task. According to the method, the probability that the second category of users participatein interaction is improved, so that the utilization efficiency of online interaction resources is improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

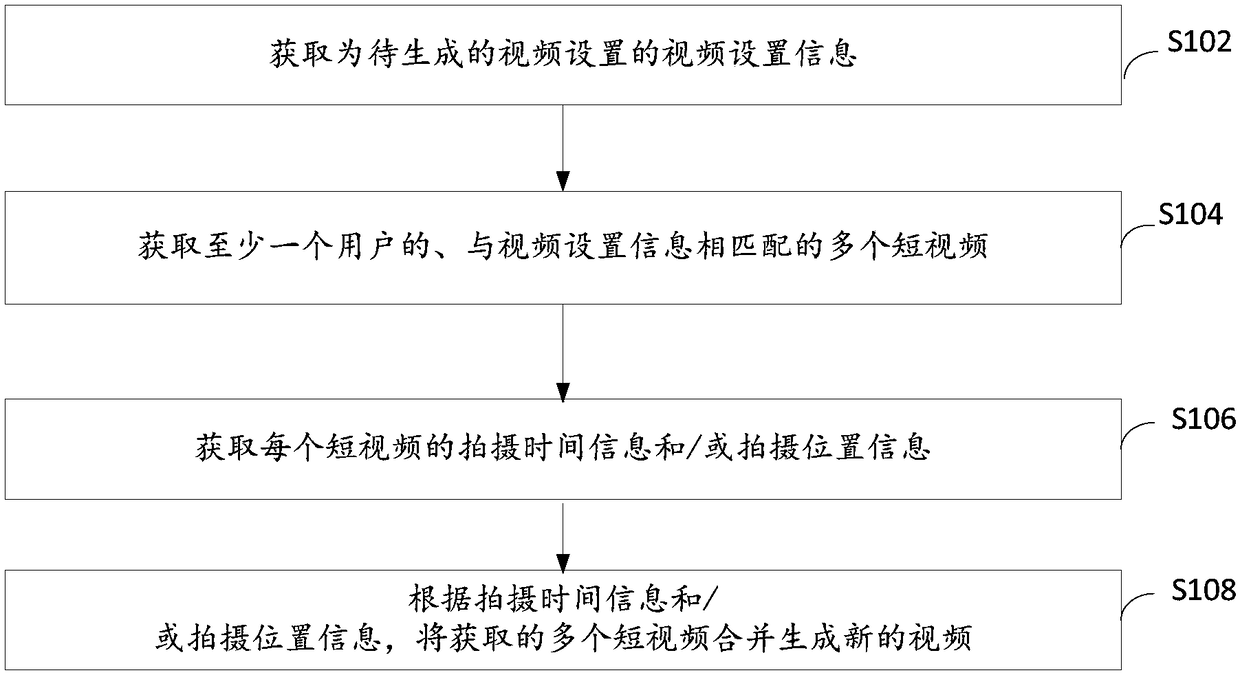

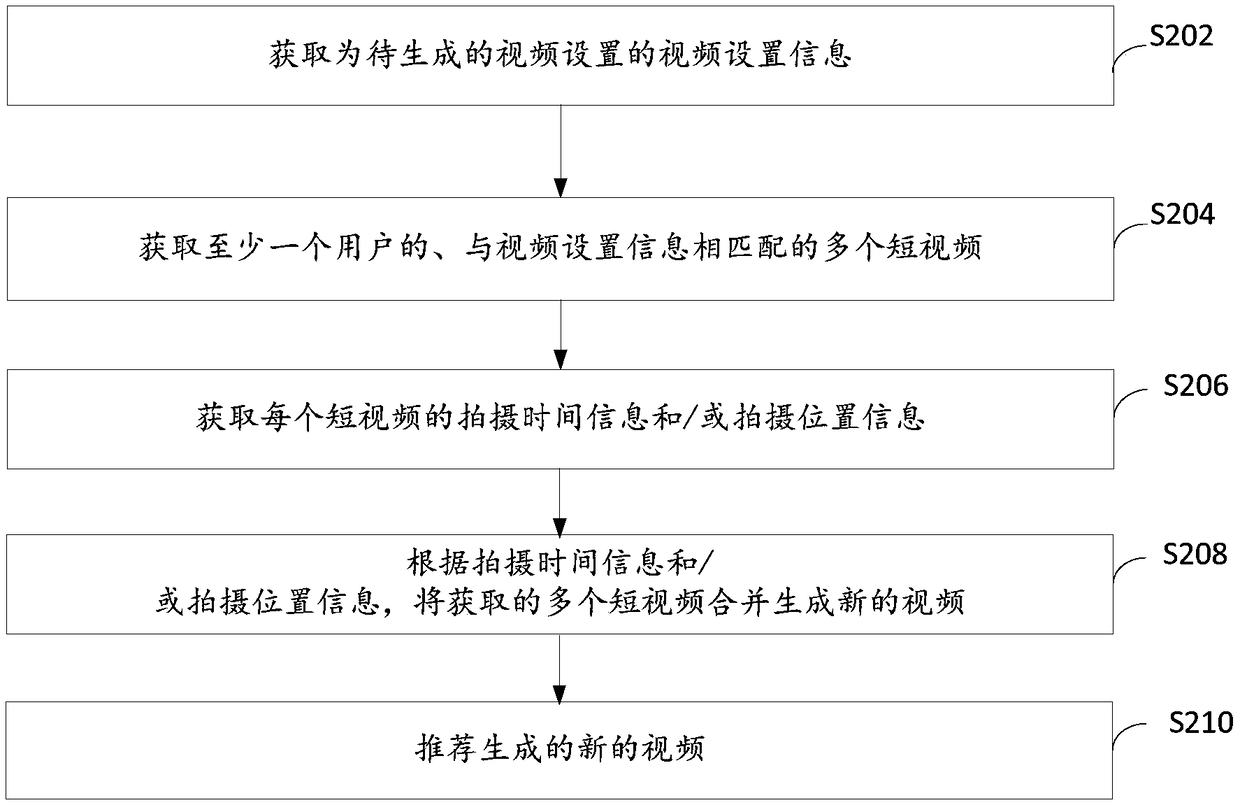

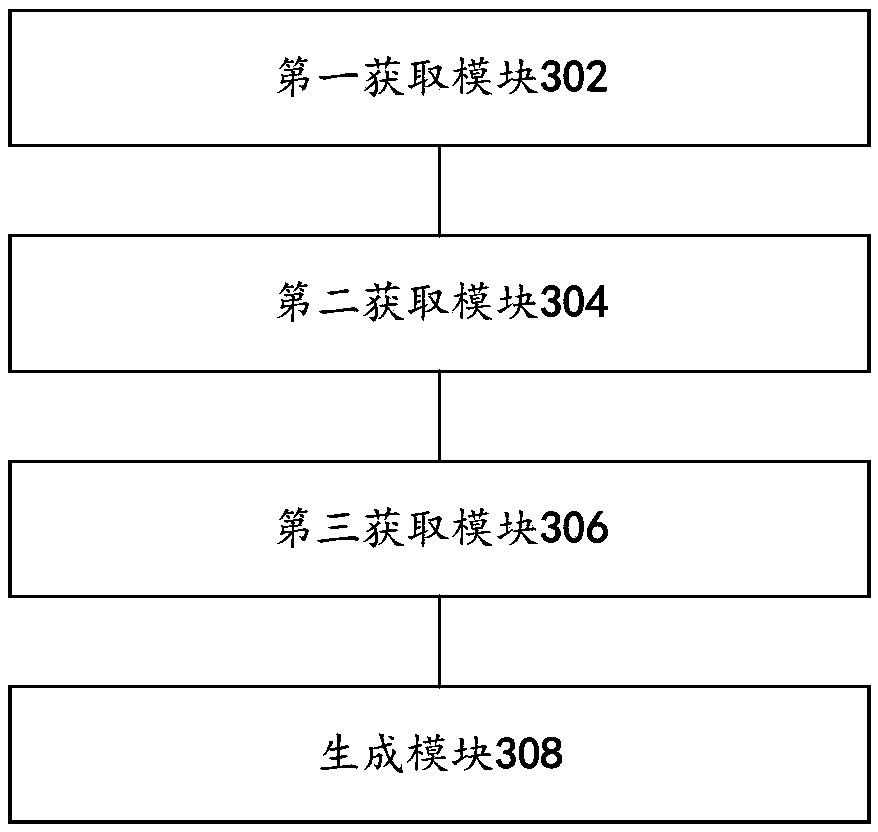

Method and device for processing video, equipment/terminal/server and computer readable storage medium

InactiveCN108965919AMeet individual needsHigh degree of associationSelective content distributionTime informationPersonalization

Embodiments of the invention provide a method and a device for processing a video, equipment / terminal / server and a computer readable storage medium, wherein the method comprises the steps of: acquiring video setting information set for a to-be-generated video, wherein the video setting information comprises time setting information and / or position setting information; acquiring a plurality of short videos matched with the video setting information from at least one user; acquiring shooting time information and / or shooting position information of the each short video; and merging the acquired plurality of short videos to generate a new video according to the shooting time information and / or the shooting position information. Through adoption of the method in the embodiment of the invention,current video contents can be enriched, at the same time, a correlation degree between the video contents and the users can be greatly improved, thereby meeting individual requirements of the users.

Owner:UCWEB SINGAPORE PTE LTD

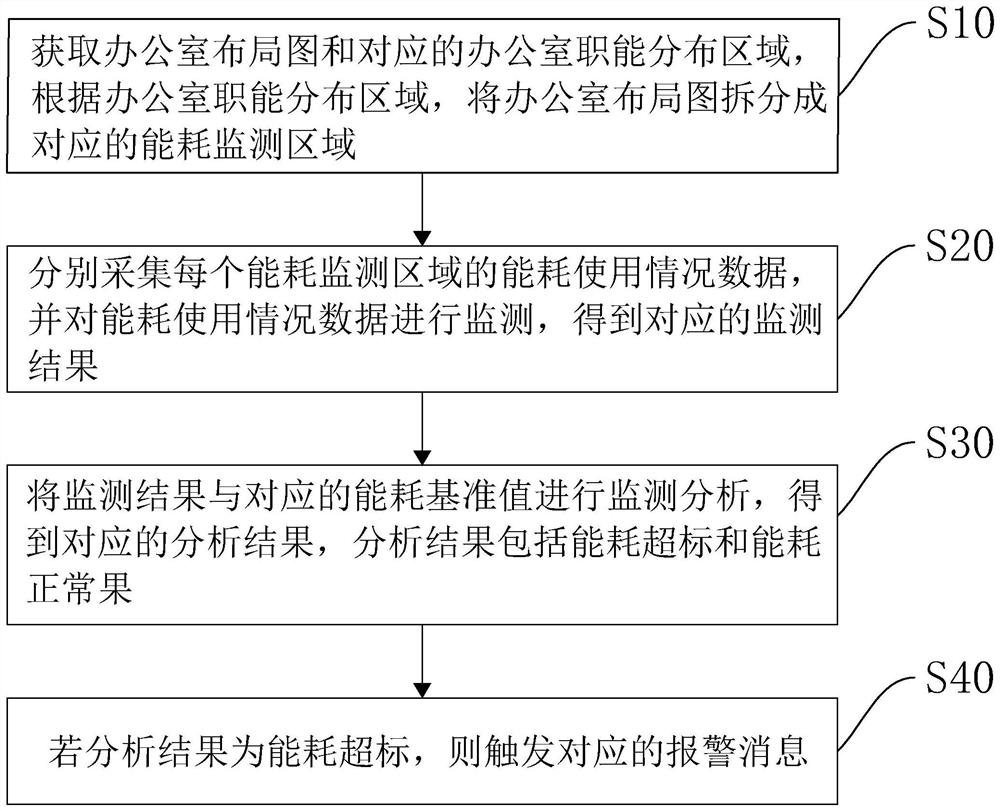

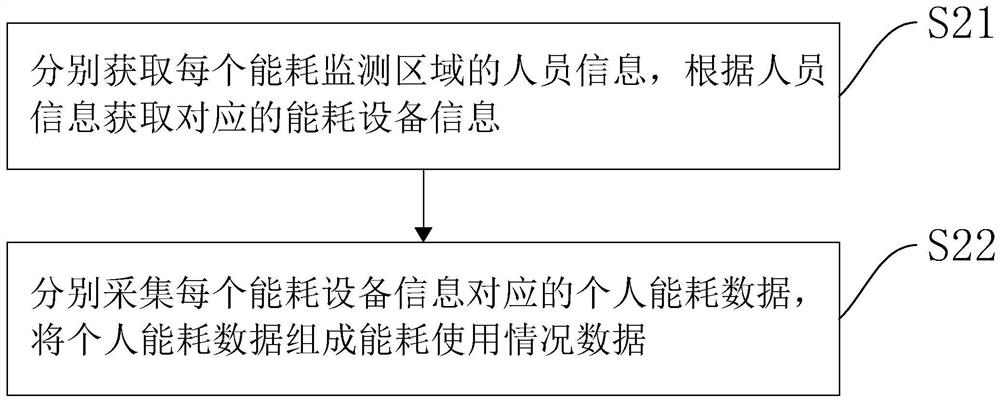

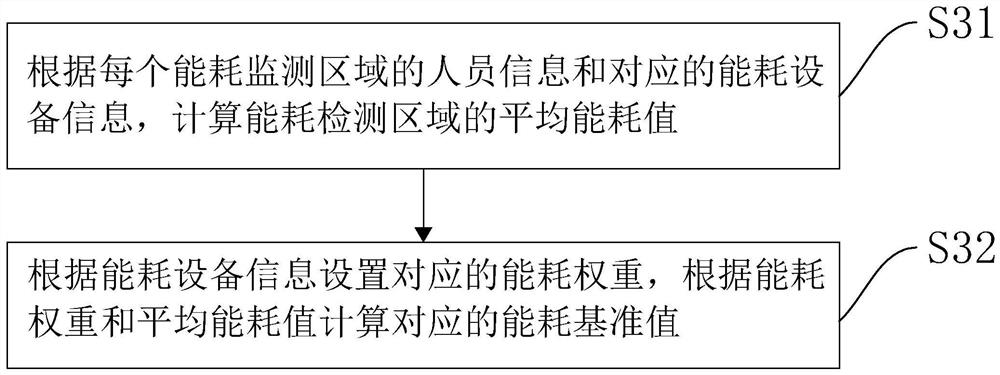

Office building independent room energy consumption collecting, monitoring, analysis and alarming system

PendingCN111929496AEasy to monitorHelp managementElectrical measurementsAlarm messageEnvironmental resource management

The invention relates to the technical field of energy monitoring, and in particular relates to an office building independent room energy consumption collecting, monitoring, analyzing and alarming system. The office building independent room energy consumption collecting, monitoring, analyzing and alarming method comprises the steps that an office layout diagram and a corresponding office function distribution area are obtained, and the office layout diagram is split into corresponding energy consumption monitoring areas according to the office function distribution area; energy consumption use condition data of each energy consumption monitoring area are collected, and the energy consumption use condition data are monitored to obtain a corresponding monitoring result; the monitoring result and the corresponding energy consumption reference value are monitored and analyzed to obtain a corresponding analysis result, and the analysis result comprises standard exceeding energy consumption and normal energy consumption; and if the analysis result shows that the energy consumption exceeds the standard, a corresponding alarm message is triggered. The system provided by the invention hasthe effects of monitoring the energy consumption in an office and giving an alarm.

Owner:广州天萌建筑设计有限公司

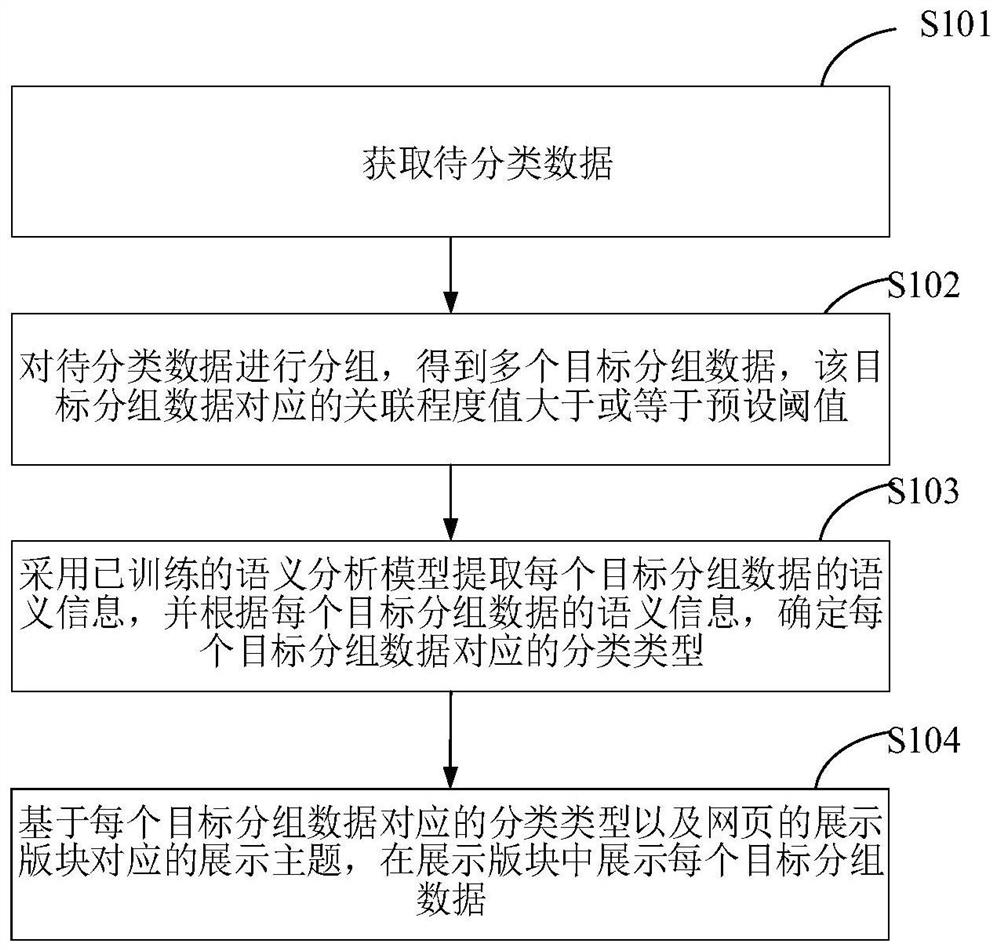

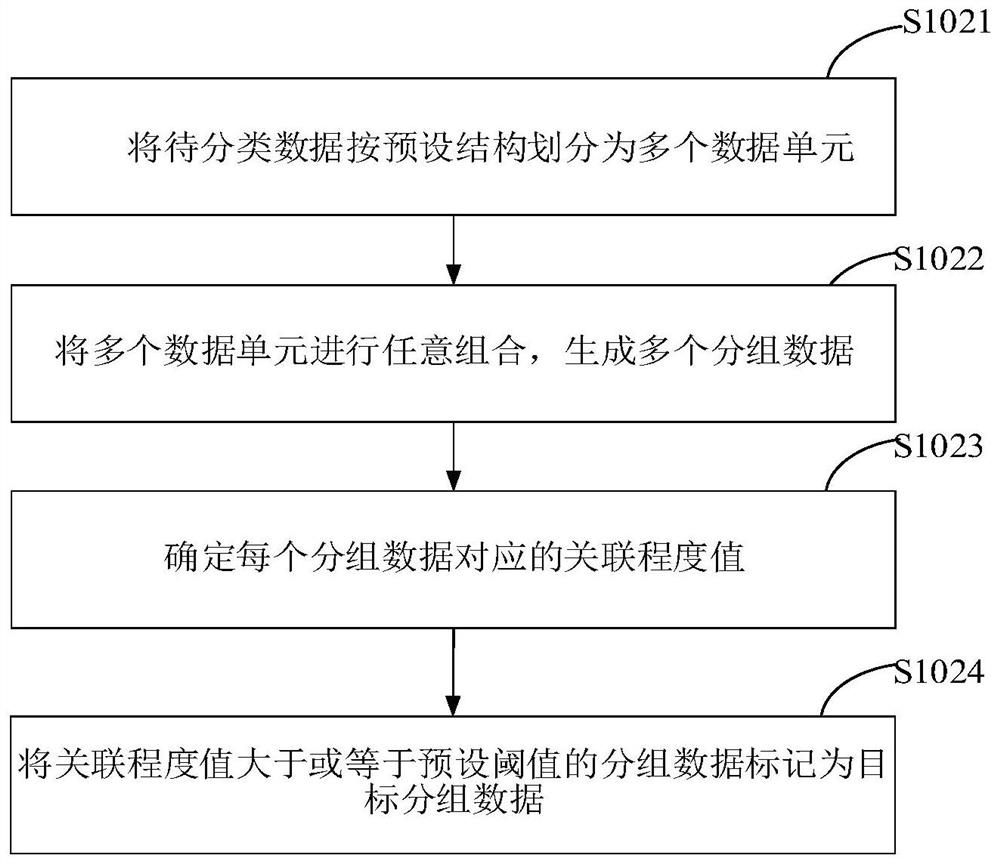

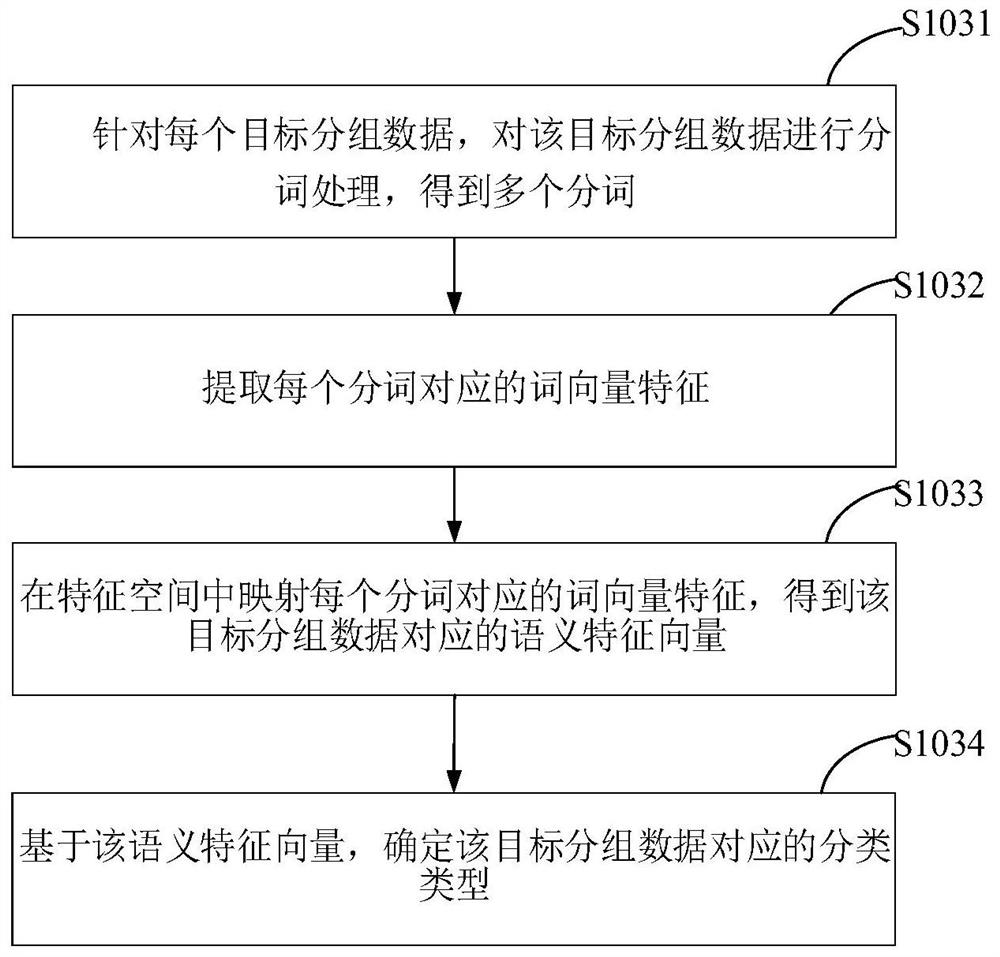

Data classification method and device, terminal and storage medium

PendingCN112818206AImprove accuracyIncrease processing rateSemantic analysisSpecial data processing applicationsAnalytic modelClassification methods

The invention is suitable for the technical field of computers, and provides a data classification method and device, a terminal and a storage medium. The method comprises the steps: obtaining to-be-classified data; grouping the to-be-classified data to obtain multiple pieces of target grouped data; adopting a semantic analysis model to extract semantic information of each piece of target grouped data, and determining a classification type corresponding to each piece of target grouped data according to the semantic information of each piece of target grouped data; and displaying each piece of target grouped data in a display section based on the classification type corresponding to each piece of target grouped data and a display theme corresponding to the display section of the webpage. According to the data classification method, the accuracy of data classification is improved, and then it is guaranteed that a user can accurately and rapidly find information wanted by the user in the webpage; and the target grouped data is processed through the semantic analysis model, and manual intervention is not needed, so that the data processing rate is increased, and the economic cost is saved.

Owner:平安消费金融有限公司

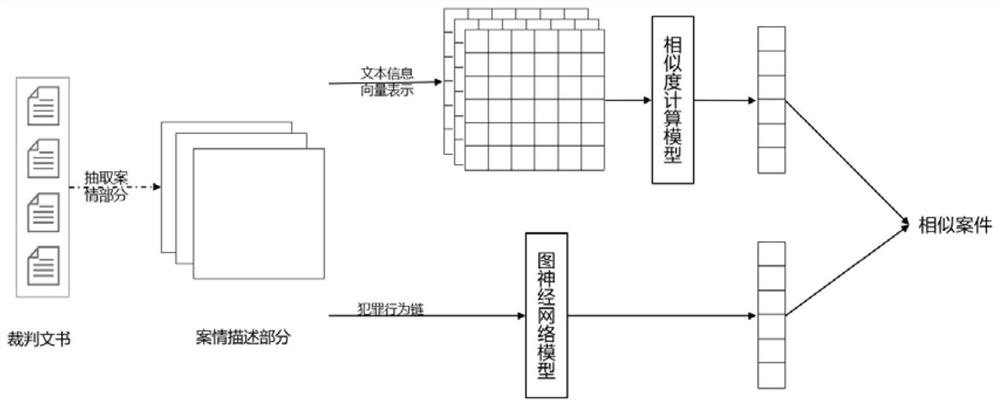

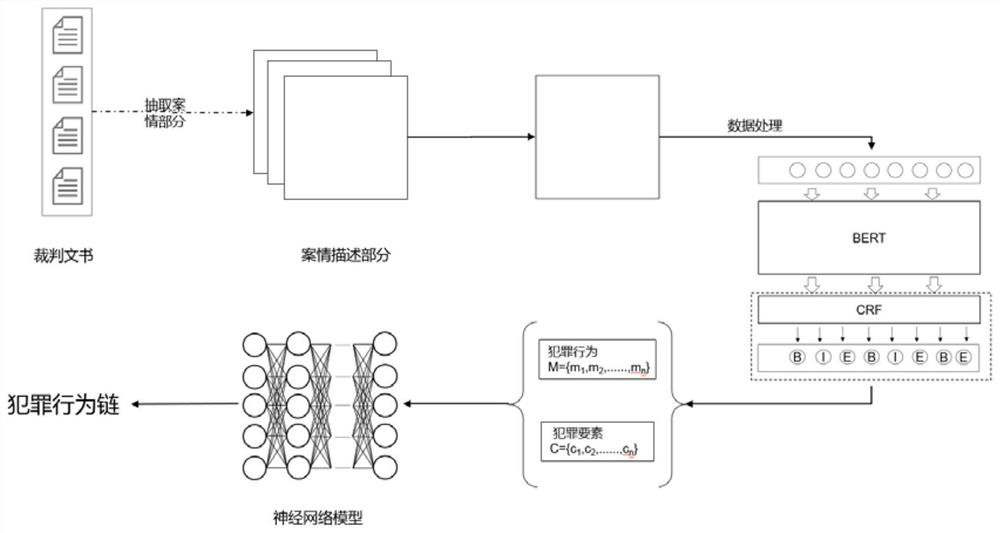

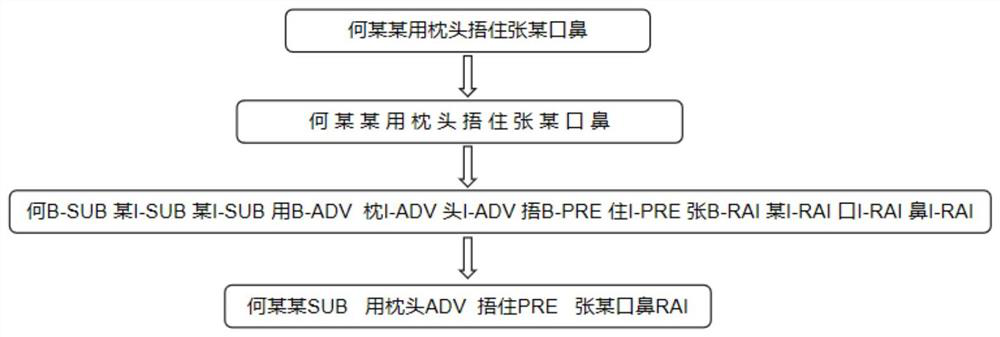

Similar case calculation method based on criminal behavior chain

InactiveCN111813906AClarify the development trendClear outlineData processing applicationsNeural architecturesTheoretical computer scienceComputational model

The invention discloses a similar case calculation method based on a criminal behavior chain, and the method comprises the following steps: 1, extracting related information from a case description part of a judgment document, employing Bert + Crf as a sequence labeling model, carrying out the extraction of key information, and finally constructing the criminal behavior chain; 2, based on the structural features of the criminal behavior chain, adopting a graph neural network model as a basic calculation model to realize similarity calculation of the criminal behavior chain; and 3, combining aresult obtained by the graph neural network model with the text content information to realize finding of similar cases by a crime behavior chain-based similarity calculation method. According to theinvention, the characteristics of a criminal behavior chain are fully utilized, a deeper calculation method is provided for traditional similar case searching, the similarity between similar cases isimproved, technical support is provided for pushing of class cases, and a very good effect is achieved.

Owner:GUIZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com