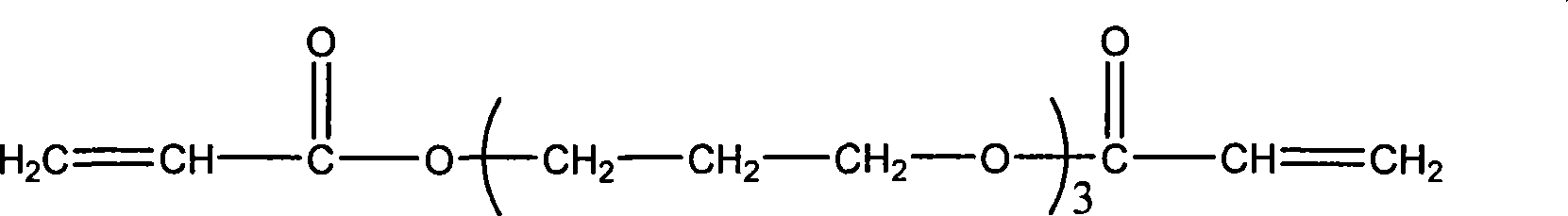

Method for preparing polymer dispersion liquid crystal material by ultraviolet-heating step-polymerization process

A technology of dispersing liquid crystal and step-by-step polymerization, used in liquid crystal materials, chemical instruments and methods, etc., can solve problems such as insufficient adhesion, detachment of ITO plastic film, and impact on product economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

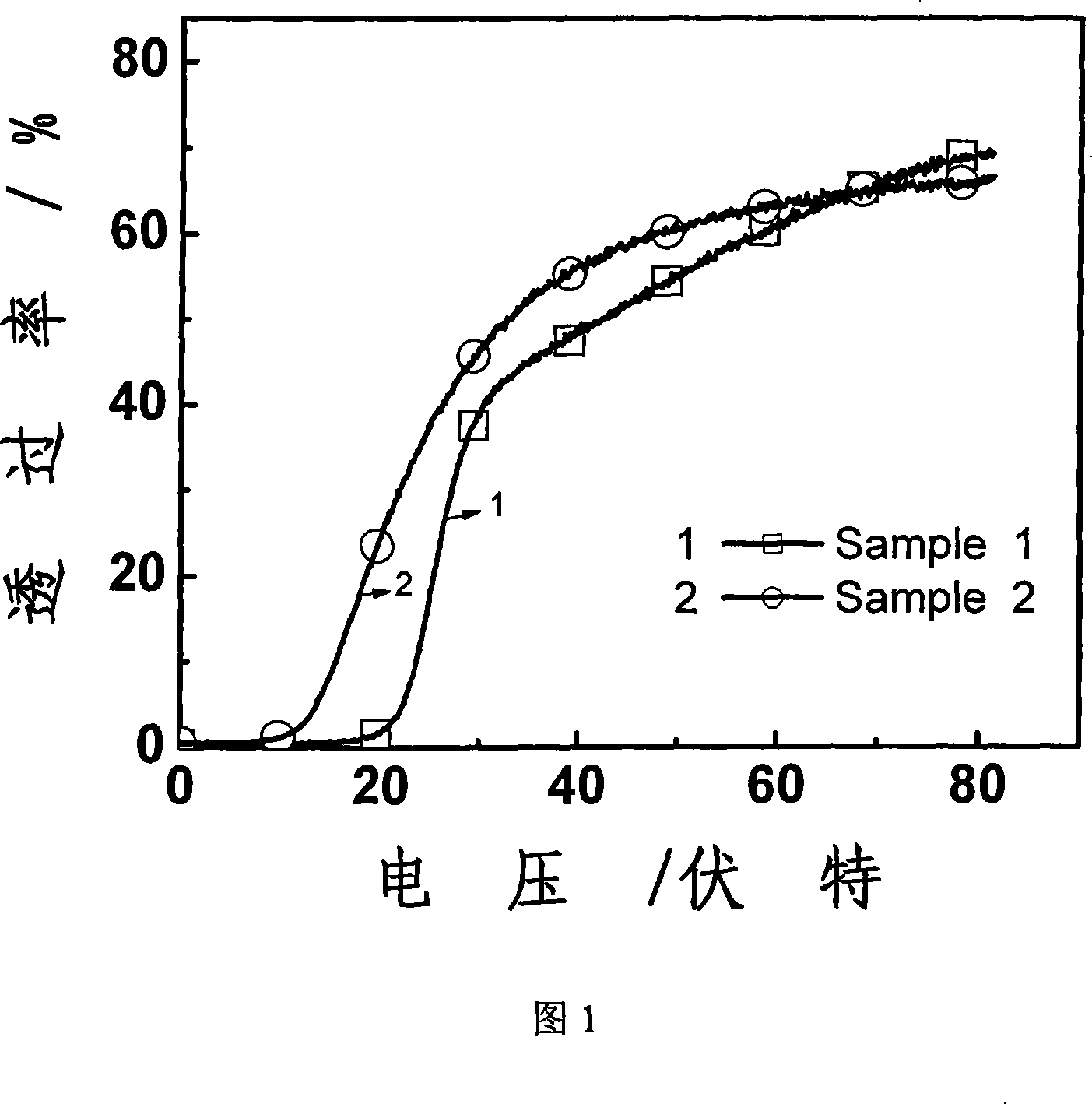

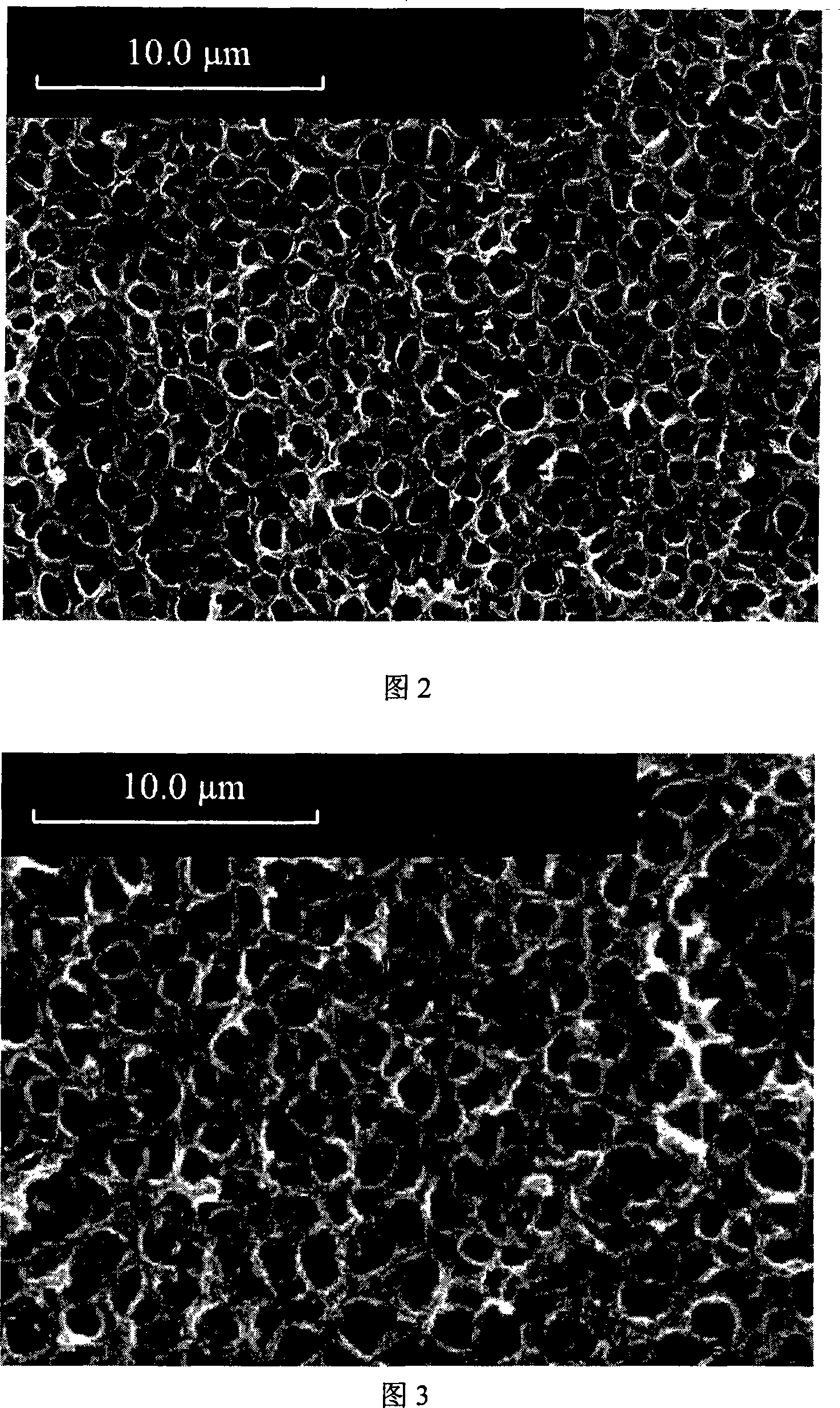

[0031] Tripropylene glycol diacrylate (TPGDA) containing acrylate functional groups and pentaerythritol triacrylate (PETA) were mixed uniformly in a mass ratio of 2:1 as a UV-polymerizable monomer; DGEBA containing conjugated epoxy groups Epoxy resin and Jeffamine D-400, an aliphatic amine epoxy curing agent, were uniformly mixed at a mass ratio of 1:1 as a UV-polymerizable monomer. The above-mentioned ultraviolet light polymerizable monomer and thermal polymerizable monomer are mixed in a mass ratio of 1.5:1, and the mixed system is used as a polymerizable monomer. The above two polymerizable monomeric materials were obtained from commercially available products without further purification. The nematic liquid crystal selected in the present invention is SLC1717 (Shijiazhuang Yongsheng Huaqing Liquid Crystal Co., Ltd., Tc=92° C.). The nematic liquid crystal and the above-mentioned compounded polymerizable monomer are uniformly mixed at a mass ratio of 7:3, and an isotropic l...

Embodiment 2

[0037]The nematic liquid crystal in embodiment 1, ultraviolet light polymerizable monomer, photoinitiator, thermopolymerizable monomer and nano microbead are uniformly mixed, after the ultraviolet light polymerization process identical with embodiment 1, the sample obtained Put it into an oven, the heating temperature is 90° C., and the heating time is 6 hours. After the sample is cooled to room temperature in the air, the PDLC film of Example 2 is obtained.

Embodiment 3

[0039] The nematic liquid crystal in embodiment 1, ultraviolet light polymerizable monomer, photoinitiator, thermopolymerizable monomer and nano microbead are uniformly mixed, after the ultraviolet light polymerization process identical with embodiment 1, the sample obtained Put it into an oven, the heating temperature is 90° C., and the heating time is 8 hours. After the sample is cooled to room temperature in the air, the PDLC film of Example 3 is obtained.

[0040] The experimental results show that the electro-optic properties of the PDLC films in Examples 2-3 are not much different from those of the PDLC films prepared in Example 1. This also shows that in the above examples, when the thermal polymerization process is heated for 5 hours, the reaction between the epoxy resin and the aliphatic amine epoxy curing agent is basically completed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com