Heat-insulating coating for inner wall

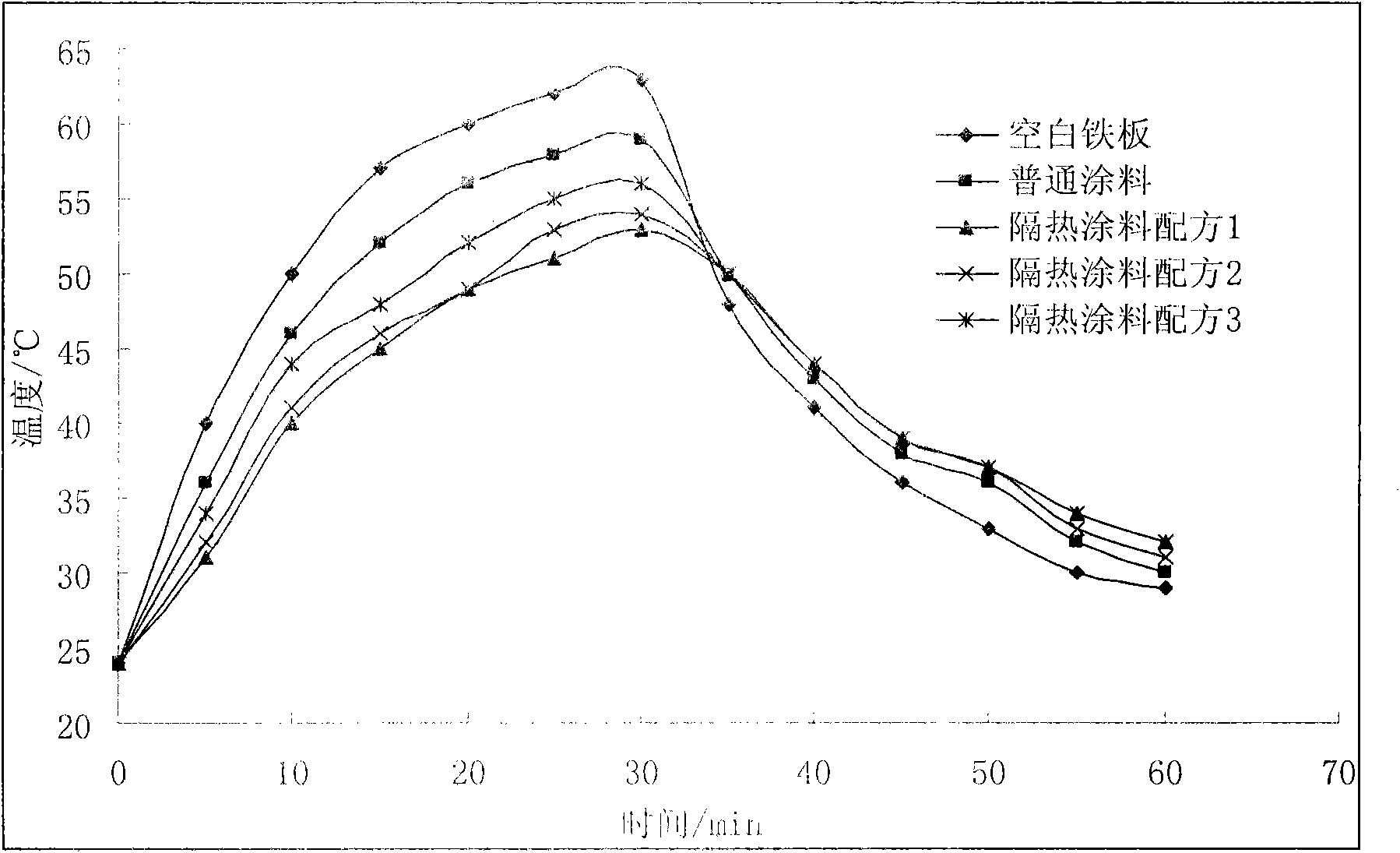

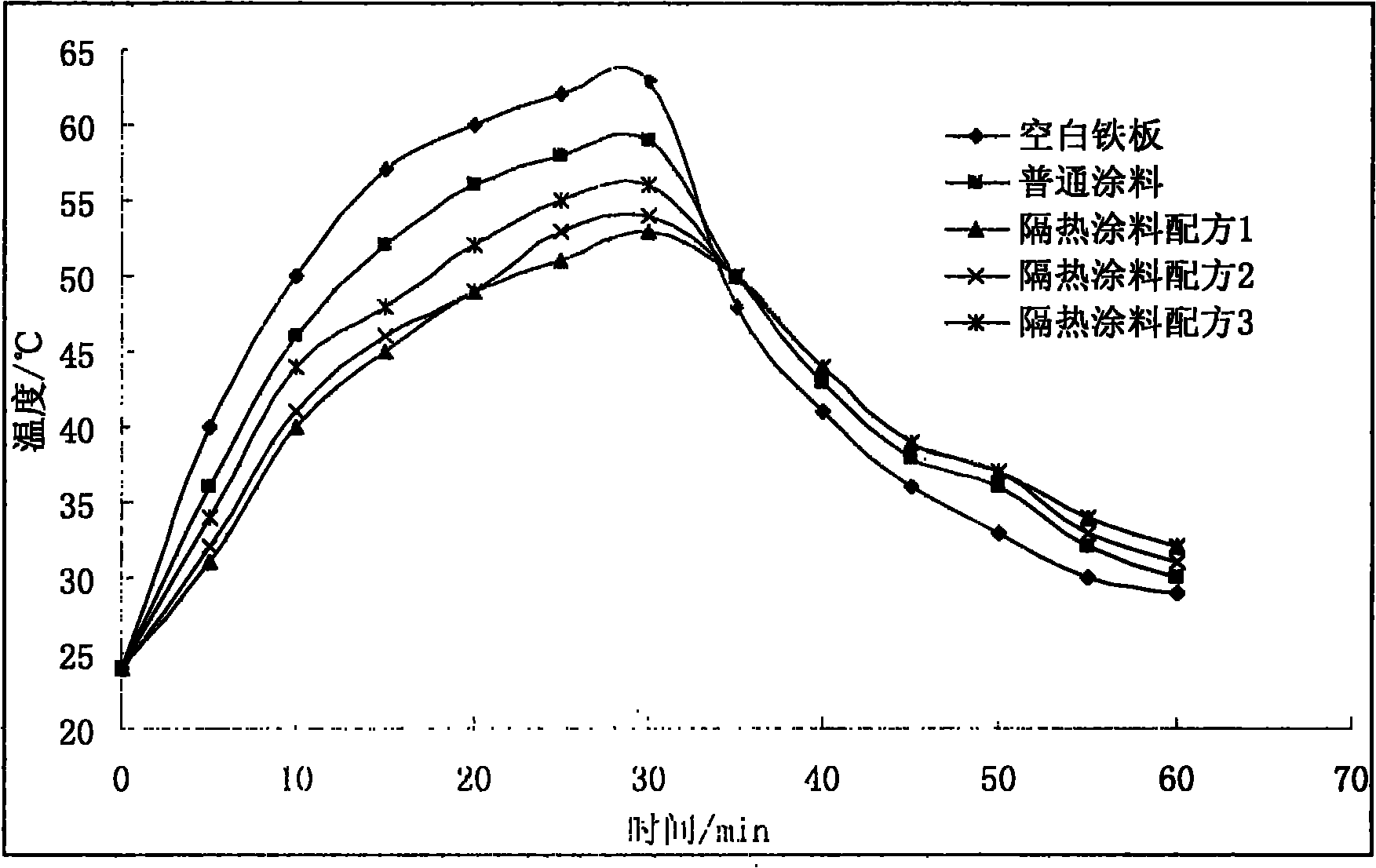

A technology for heat insulation and coating, applied in the direction of coating, can solve the problems of unsatisfactory effect and reduce the thermal conductivity of coating, and achieve the effect of low density, low thermal conductivity and slow temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

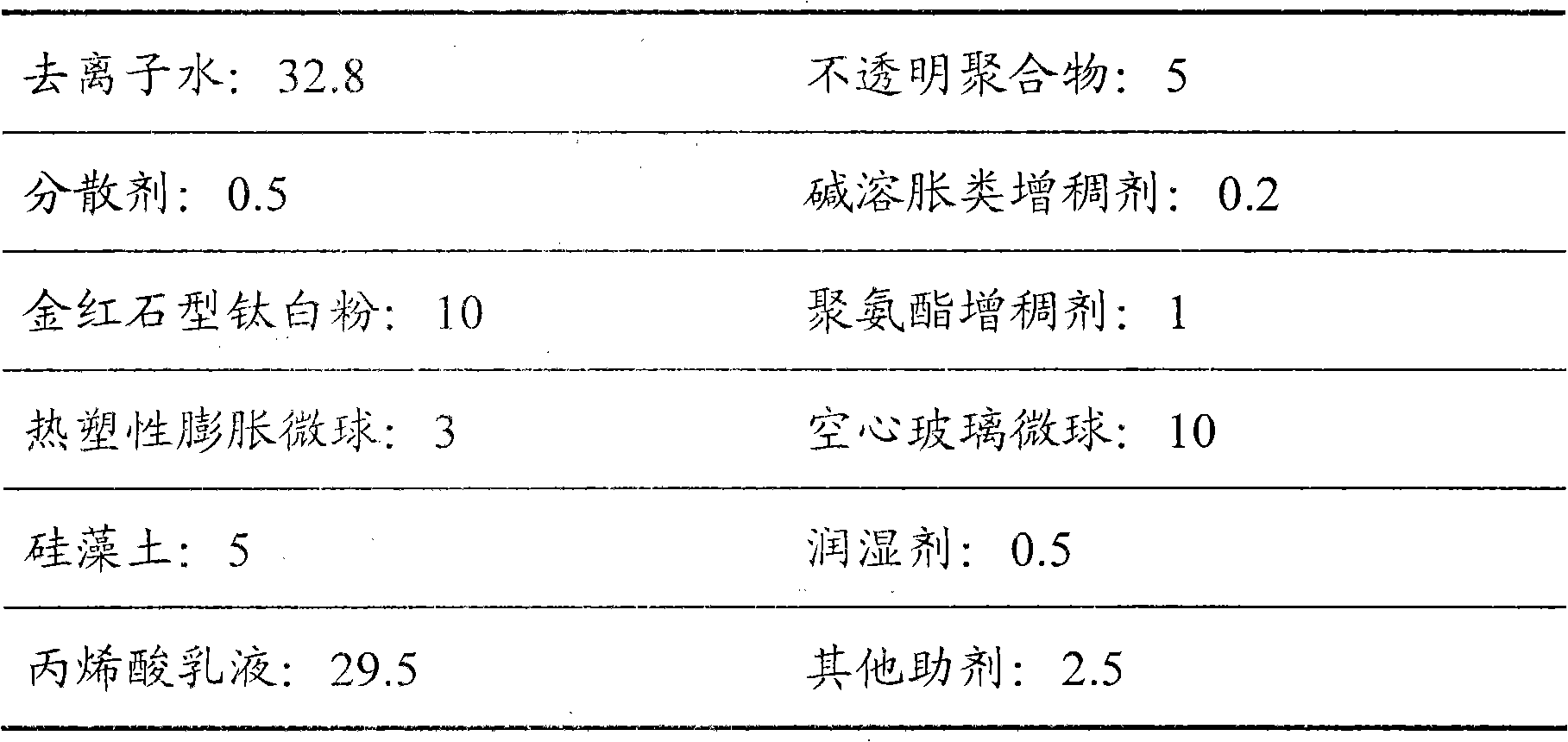

[0036] The specific implementation method: novel thermal insulation coating, its formula ratio is (percentage by weight):

[0037]

[0038] The manufacturing method of the new thermal insulation coating, first weigh the raw materials according to the formula ratio, add 15 parts of deionized water, 0.5 parts of wetting agent, 0.5 parts of dispersing agent, 10 parts of rutile titanium dioxide, 5 parts of diatomaceous earth, polyurethane 0.5 parts of thickener, after the above raw materials are added, disperse at high speed for 15 minutes, then stir at medium speed, add 29.5 parts of emulsion, 10 parts of hollow glass microspheres, 5 parts of opaque polymer, add alkali swelling thickener under low speed stirring 0.2 parts and 0.5 parts of polyurethane thickener, add thermoplastic expansion microspheres, remaining water and other ingredients, stir for 15 minutes, filter, weigh and pack.

Embodiment 2

[0040] The formula ratio of the new thermal insulation coating is (percentage by weight):

[0041]

[0042] The manufacturing method of the new thermal insulation coating: first weigh the raw materials according to the formula ratio, add 15 parts of deionized water, 0.5 parts of wetting agent, 0.5 parts of dispersing agent, 10 parts of rutile titanium dioxide, 10 parts of diatomaceous earth, polyurethane 0.5 parts of thickener, after the above raw materials are added, disperse at high speed for 15 minutes, then stir at medium speed, add 31.5 parts of emulsion, 8 parts of hollow glass microspheres, 3 parts of opaque polymer, add alkali swelling thickener under low speed stirring 0.2 parts and 0.5 parts of polyurethane thickener, add thermoplastic expansion microspheres, remaining water and other ingredients, stir for 15 minutes, filter, weigh and pack.

Embodiment 3

[0044] The formula ratio of the new thermal insulation coating is (percentage by weight):

[0045]

[0046]

[0047] The manufacturing method of the new thermal insulation coating: first weigh the raw materials according to the formula ratio, add 15 parts of deionized water, 0.5 parts of wetting agent, 0.5 parts of dispersing agent, 12 parts of rutile titanium dioxide, 8 parts of diatomaceous earth, polyurethane 0.5 parts of thickener, after the above raw materials are added, disperse at high speed for 15 minutes, then stir at medium speed, add 33.5 parts of emulsion, 5 parts of hollow glass microspheres, 10 parts of opaque polymer, add alkali swelling thickener under low speed stirring 0.2 parts and 0.5 parts of polyurethane thickener, add thermoplastic expansion microspheres, remaining water and other ingredients, stir for 15 minutes, filter, weigh and pack.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com