Soft chemical preparation method for hollow glass micro-balloon, prepared hollow glass micro-balloon and application thereof

A hollow glass microsphere, soft chemical technology, applied in the field of soft chemical method, can solve the problems of high cost, low energy consumption, difficult to control particle size distribution and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

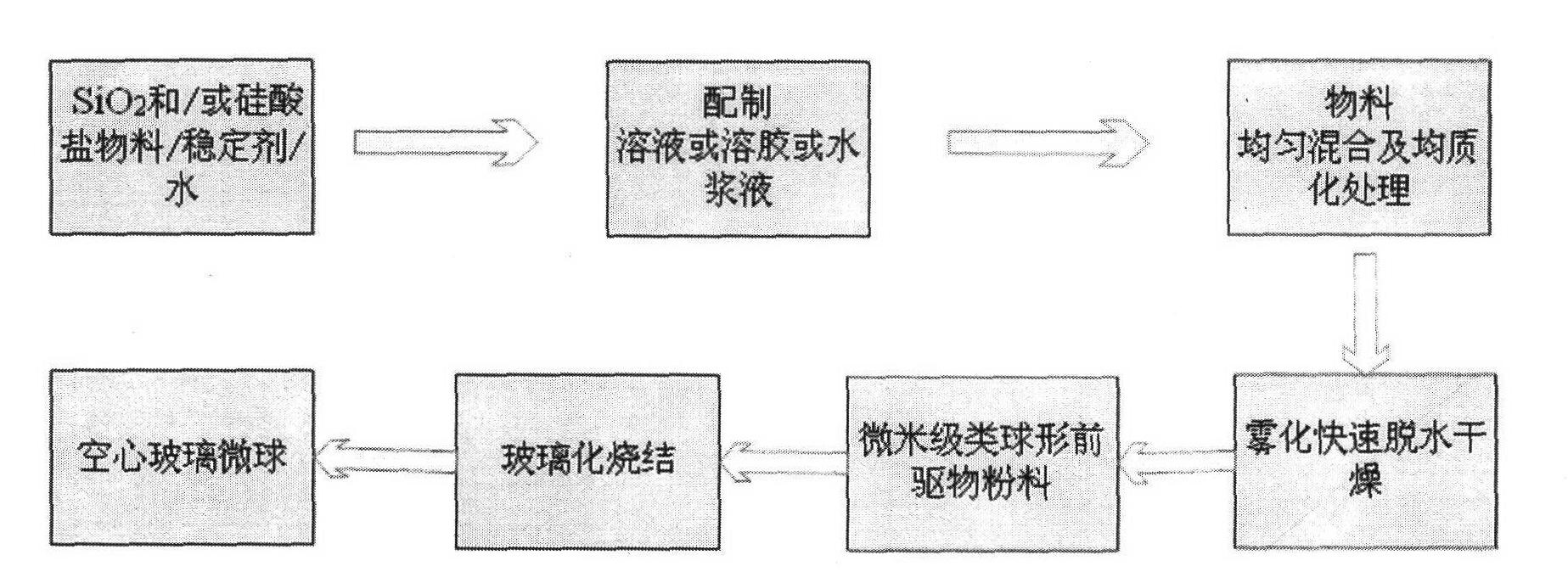

Method used

Image

Examples

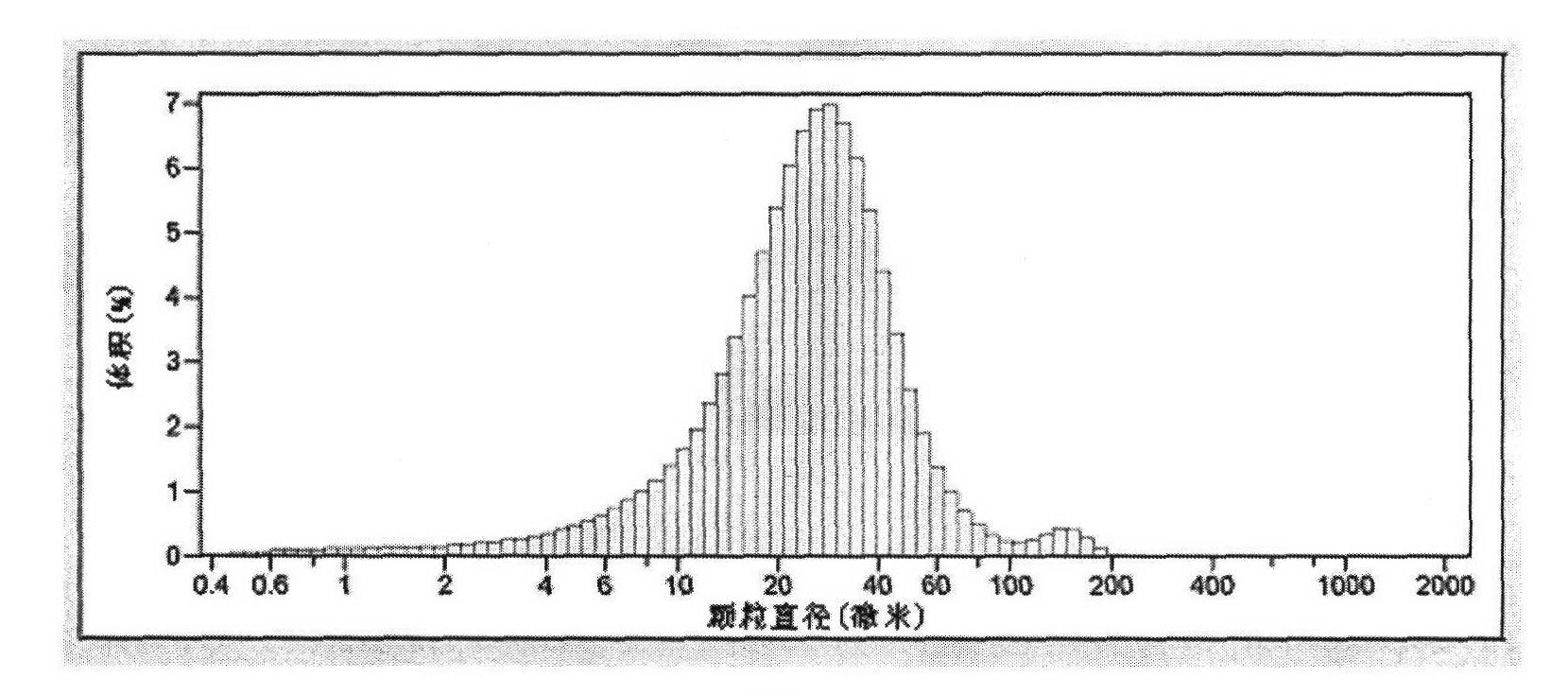

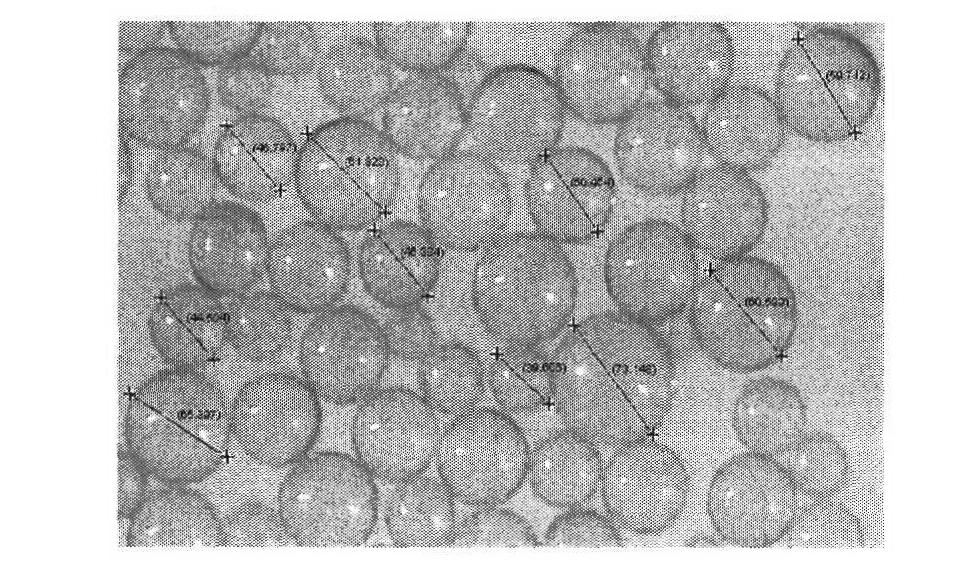

Embodiment 1

[0041] The first step is the synthesis of the feed-liquid system of hollow glass microspheres:

[0042] Mix 4000g slurry containing 600g fumed silica and 485g sodium silicate solution (containing 121g of silicon dioxide and 39g of sodium oxide) with 517g containing 60g of borax, 60g of sodium nitrate, 90g of calcium carbonate, 40g of magnesium chloride, and 40g of potassium nitrate 1. The aqueous solution of 20g of lithium carbonate is prepared into a water slurry material, and then it is fully mixed with a high-speed mixer at 30°C and normal pressure, and after reaction, 200ml of high molecular polymer glue containing 10g of stable dispersant polyethylene oxide is added , Grinding by a colloid mill to form a homogenized slurry, so that the particle size of the solid particles in the slurry is at least less than 2 microns. Wherein, gas-phase silica and sodium silicate account for 15.2% by weight in the feed liquid, inorganic salts account for 6.2% by weight in the feed liquid,...

Embodiment 2

[0046] The first step is the synthesis of the feed-liquid system of hollow glass microspheres:

[0047] Prepare 4000g of slurry containing 600g of gas-phase self-carbon black and 364g of sodium silicate solution (containing 91g of silicon dioxide and 29g of sodium oxide) and 350g of aqueous solution containing 40g of borax, 60g of sodium sulfate, 90g of calcium nitrate, and 20g of potassium nitrate Form a water slurry material, then fully mix it with a high-speed mixer at 30°C and normal pressure, after reaction, add 200ml of high-molecular polymer glue containing 5.5g of stable dispersant polyethylene oxide, and grind it through a colloid mill to form Homogenized slurry, so that the particle size of solid particles in the slurry is at least less than 2 microns. Wherein, gas-phase silica and sodium silicate account for 15.3% by weight in the feed liquid, inorganic salts account for 4.5% by weight in the feed liquid, and stable dispersants account for 0.12% by weight in the fee...

Embodiment 3

[0051] The first step is the synthesis of the feed-liquid system of hollow glass microspheres:

[0052] Mix 3333g slurry containing 500g fumed silica and 198g sodium potassium silicate solution (containing 53.3g of silicon dioxide, 8.9g of sodium oxide, and 17.8g of potassium oxide) with 440g of 60g of boric acid, 50g of sodium sulfate, and 90g of calcium carbonate , 20g of magnesium sulfate aqueous solution is prepared into a water slurry material, and then it is fully mixed with a high-speed mixer at 80°C and normal pressure, and after reaction, add a high molecular polymer glue containing 5.0g of a stable dispersant polyethylene oxide 200ml, through the colloid mill to form a homogenized slurry, so that the particle size of the solid particles in the slurry is at least less than 2 microns. Wherein, gas-phase silica and potassium sodium silicate account for 14.6% by weight in the feed liquid, inorganic salts account for 5.5% by weight in the feed liquid, and stable dispersan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com